Scientists from Germany and Italy have collaborated on a new paper in the journal Polymers exploring the properties of edible polymers and bioactive compounds which can be used as food packaging.

Study: Edible Polymers and Secondary Bioactive Compounds for Food Packaging Applications: Antimicrobial, Mechanical, and Gas Barrier Properties. Image Credit: Igor Kovalchuk/Shutterstock.com

Conventional Food Packaging

Conventional food packaging is made from polymers manufactured from fossil fuels. Whilst these materials have beneficial characteristics such as good mechanical and physio-chemical properties, durability, and waterproofing abilities, there are several drawbacks to them.

Traditional fossil-fuel-based polymers used in food packaging are not biodegradable, and once disposed in the environment can last for a long time. They can degrade via mechanical, thermal, and bacterial means to produce toxic by-products and microplastics. Furthermore, due to factors such as contamination with organic material, they are difficult to recycle.

Food packaging is responsible for around one-third of all plastic waste which enters the environment. Due to the scale of this problem, scientists have investigated alternative, biodegradable, and environmentally friendly food packaging materials.

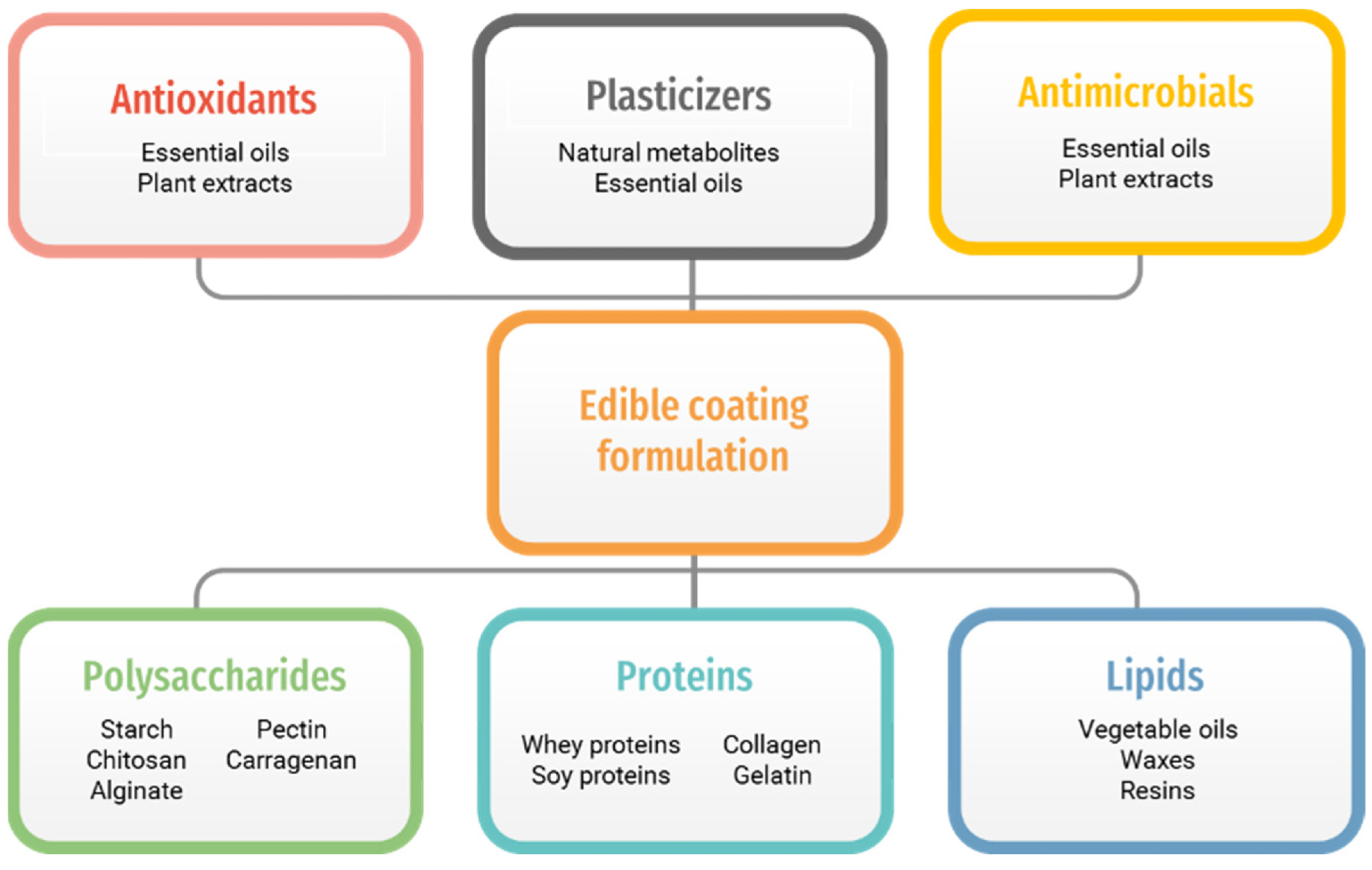

The main components of the edible coating formulations. Image Credit: Moeini, A et al., Polymers

Biopolymers – Improving Food Packaging Eco-friendliness

Several alternative green food packaging technologies have been investigated in recent years. Bio-based polymers have emerged as a forerunner in eco-friendly food packaging research. These materials have the benefits of being biodegradable, compostable, and renewable as they come from abundant organic resources.

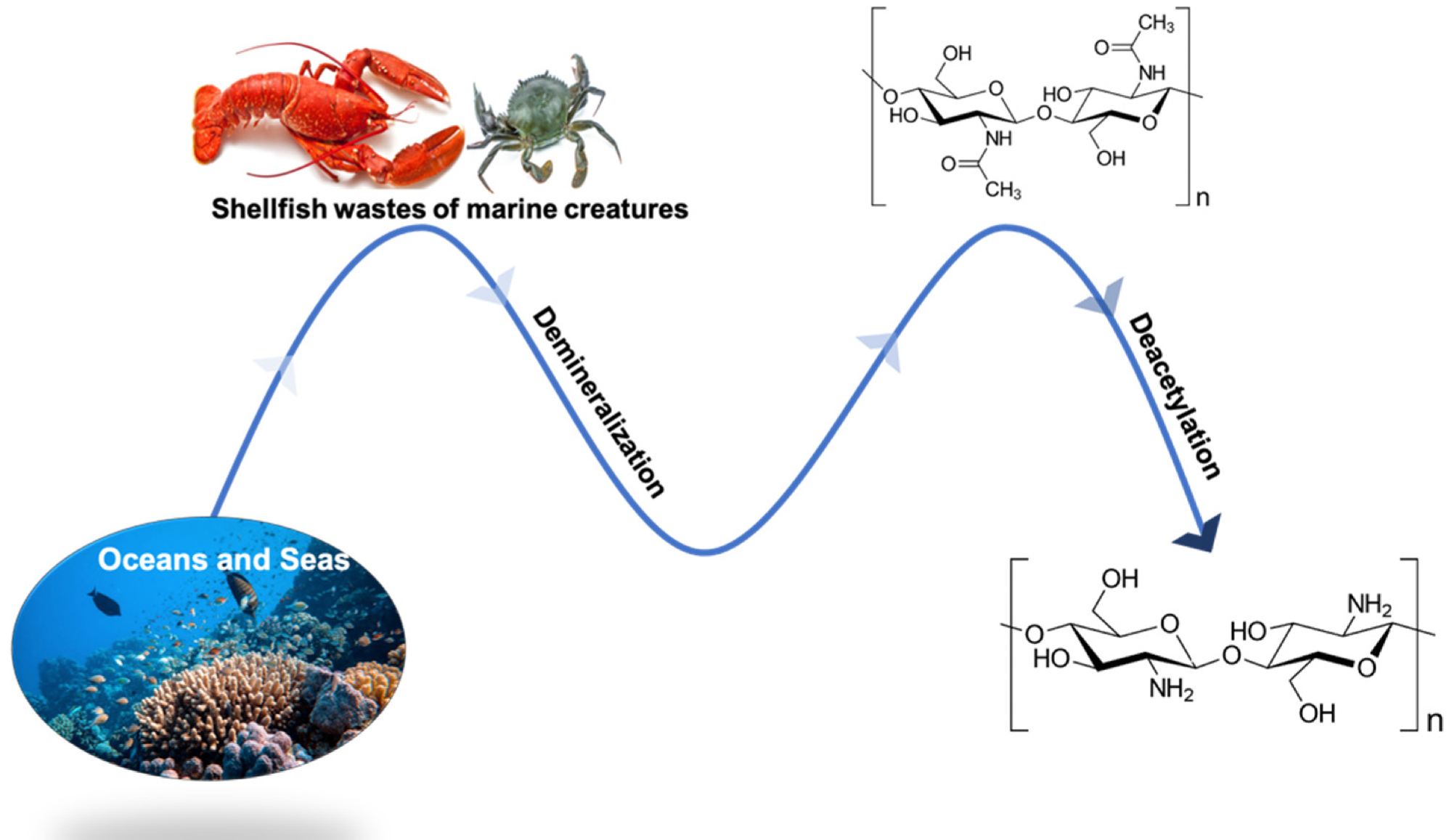

Biopolymers can be derived from a variety of sources such as oil, vegetables, animals, microorganisms, and proteins. Biopolymers have beneficial characteristics such as excellent gas barrier properties, which can be reduced by the addition of fillers and plasticizers. Additionally, they possess suitable mechanical, antimicrobial, and antioxidant properties.

Biopolymers extend the shelf life of food, as well as enhancing the sensorial and organoleptic properties of encased food products. They are highly advantageous compared to conventional food preservation techniques such as salting and heat treatments which can alter the texture, color, taste, and odor of foods.

Biopolymers derived from proteins, polysaccharides, and lipids have been widely explored in recent years as edible food packaging, though some technical challenges exist with their development. Low cost, biocompatibility, biodegradability, and industrial scalability make them particularly attractive candidates for this use.

The chitin and chitosan manufacturing process. Image Credit: Moeini, A et al., Polymers

Active Packaging and Secondary Metabolites

There has been a recent trend towards manufacturing active food packaging with enhanced functionalities such as sensing and antimicrobial activity by incorporating active agents and nano-scaled components. This type of packaging can be used to prevent food deterioration by incorporating materials which interact with it or remove the headspace between food and packaging.

Secondary metabolites from organisms such as fungi and microorganisms have shown great promise for active packaging applications. Aside from acting as antimicrobial and antioxidant agents, they can be used as fillers in active packaging to improve mechanical properties. By modifying the bioplastic’s plasticizing characteristics, additives can enhance their commercial viability by making them comparable to conventional synthetic polymers.

The Study

The new review paper in Polymers focuses on biopolymers used as edible coatings. The effect of secondary metabolites on plasticizing, antioxidant, and antimicrobial properties of edible biopolymer food packaging has been specifically discussed by the authors. Furthermore, their use as active agents for active packaging applications has been explored in-depth in the paper.

The authors have stated that there is a wide array of general research into edible coatings, but there is a lack of study which addresses the specific research question the authors aim to answer. One hundred and seventy-nine papers in the current literature have been reviewed by the authors.

Study Findings

The paper has thoroughly reviewed several key research areas in biopolymers and edible packaging. Multiple fungi and plant secondary metabolites have been explored in the review study, which can be exploited to enhance the functionality of biopolymer-based edible food packaging. The properties of materials depend on the interaction between polymer, food substrate, and secondary metabolites.

The functionality and efficiency of these materials depends on the biopolymer’s matrix, such as resins, proteins, and polysaccharides. Additionally, it depends on additives and plasticizers. Other factors which influence the overall performance of prepared materials include the structure and functional groups of additives and polymer matrices.

Edible food packaging incorporating biopolymers and secondary components can be used to preserve a variety of foodstuffs including meats, fruit, and vegetables. As they are edible, there is no waste, which significantly improves the environmental friendliness of the food packaging industry.

Mechanical tests confirmed the performance of edible packaging. The effectiveness of additives depends on polymer matrix constitution, formulation, preparation methods, conditions, and microstructural interactions in the material.

Drawbacks have been highlighted in the study, including the hydrophilicity of biopolymers. This can be overcome with the incorporation of additives such as lipophilic compounds. Additionally, the review has highlighted the need for further investigation of secondary compounds to assess their potential toxicity and studies on developing green, standardized, and cost-effective processes are required.

Future research perspectives highlighted in the paper include industrial and academic research on edible film-forming mechanisms, secondary compound optimization, and improving the functionality and performance of edible food packaging materials. This will improve the industrial scalability and commercial viability of edible food packaging.

Further Reading

Moeini, A et al. (2022) Edible Polymers and Secondary Bioactive Compounds for Food Packaging Applications: Antimicrobial, Mechanical, and Gas Barrier Properties Polymers 14(12) 2395 [online] mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/12/2395

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.