These coatings have received research attention in recent years for self-cleaning, de-icing, drag reduction, and corrosion resistance, to name but a few important applications. Superhydrophobic coatings have specific requirements, and cooperation between the composite structure and low-surface energy modifiers is the basis for manufacturing these advanced materials.

Researchers have used several materials such as silicon dioxide and carbon nanotubes to produce powders and coatings via processes such as graft coating, sol-gel methods, and hydrothermal synthesis. These are then dipped or sprayed to produce coatings.

Other processes include dissolution and mechanical abrasion of the surface of bulk materials such as aluminum, followed by spraying with modified nanoparticles. Whilst these processes can create superhydrophobic coatings with adequate properties, they are complex and costly, hindering their commercial and practical application.

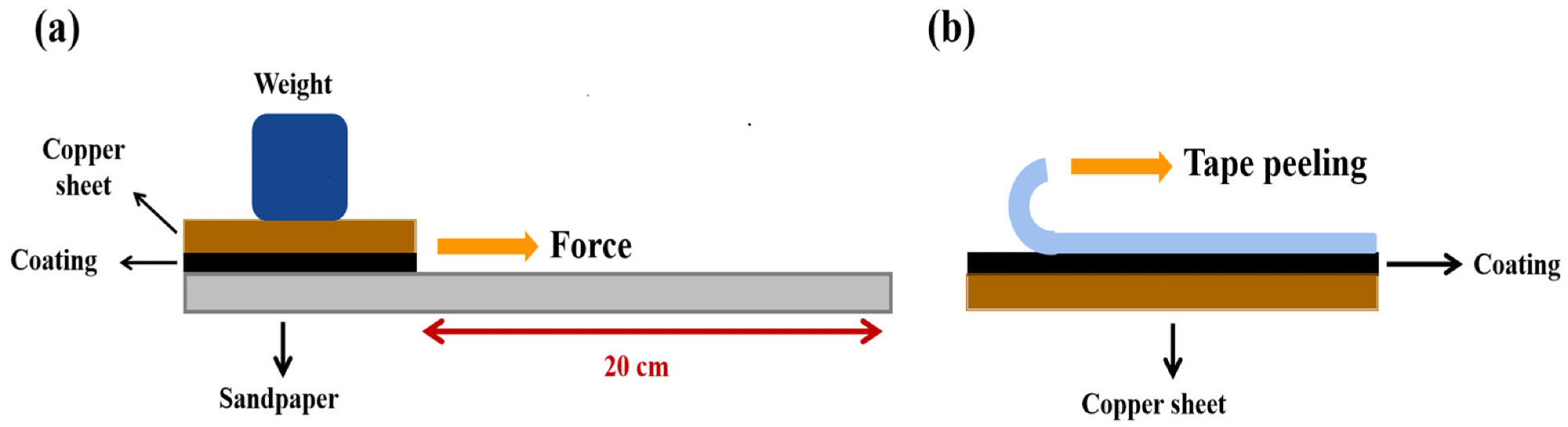

Image Credit: Su, Z et al., Materials

Improving Coatings

The complexity of current preparation processes has facilitated research into alternative, low-cost, facile strategies. Ceramics have been explored as materials for coatings due to their cost-effectiveness and abundance. Researchers have modified these ceramics with coupling agents and incorporated adhesives to synthesize coatings.

Other studies have explored alternative strategies to manufacture these coatings. Scientists have created several coatings with enhanced transparency, mechanical properties, and chemical stability. However, there are issues with the scarcity of high-quality ceramic materials and cost.

Due to the problems with sourcing abundant and cost-effective raw materials for superhydrophobic coating manufacture, research has turned to the exploitation of waste streams. Using waste materials has the benefits of low cost, sustainability, abundance, renewability, and meets the specific demands of the circular economy concept.

Iron Ore Tailings and Rubber Materials

Iron ore tailings are a critical waste material in the mining and mineral processing industries. They have already been widely explored for applications in sectors such as construction, used as cement clinker and other value-added products. These tailings have a similar composition to clay, making them ideal materials for coatings, with the added bonus of enhanced stability and wider abundance.

Rubber materials possess properties such as wear resistance and elasticity. These materials have been widely studied in several industrial applications, possessing better performance than traditional polyurethane and epoxy adhesives. Incorporating these materials into coatings improves their elasticity and durability, imparting them with enhanced wear resistance capabilities.

Studies have been performed into the effects of rubber materials on coatings, with one study using an adhesive primer made from silicon rubber on an aluminum substrate and then spraying it with a mixture of polymers and multi-walled CNTs to increase thermal stability. A hydrophobic layer of silica and ethylene rubber was incorporated, and the coating was heat cured to impart it with superhydrophobic properties.

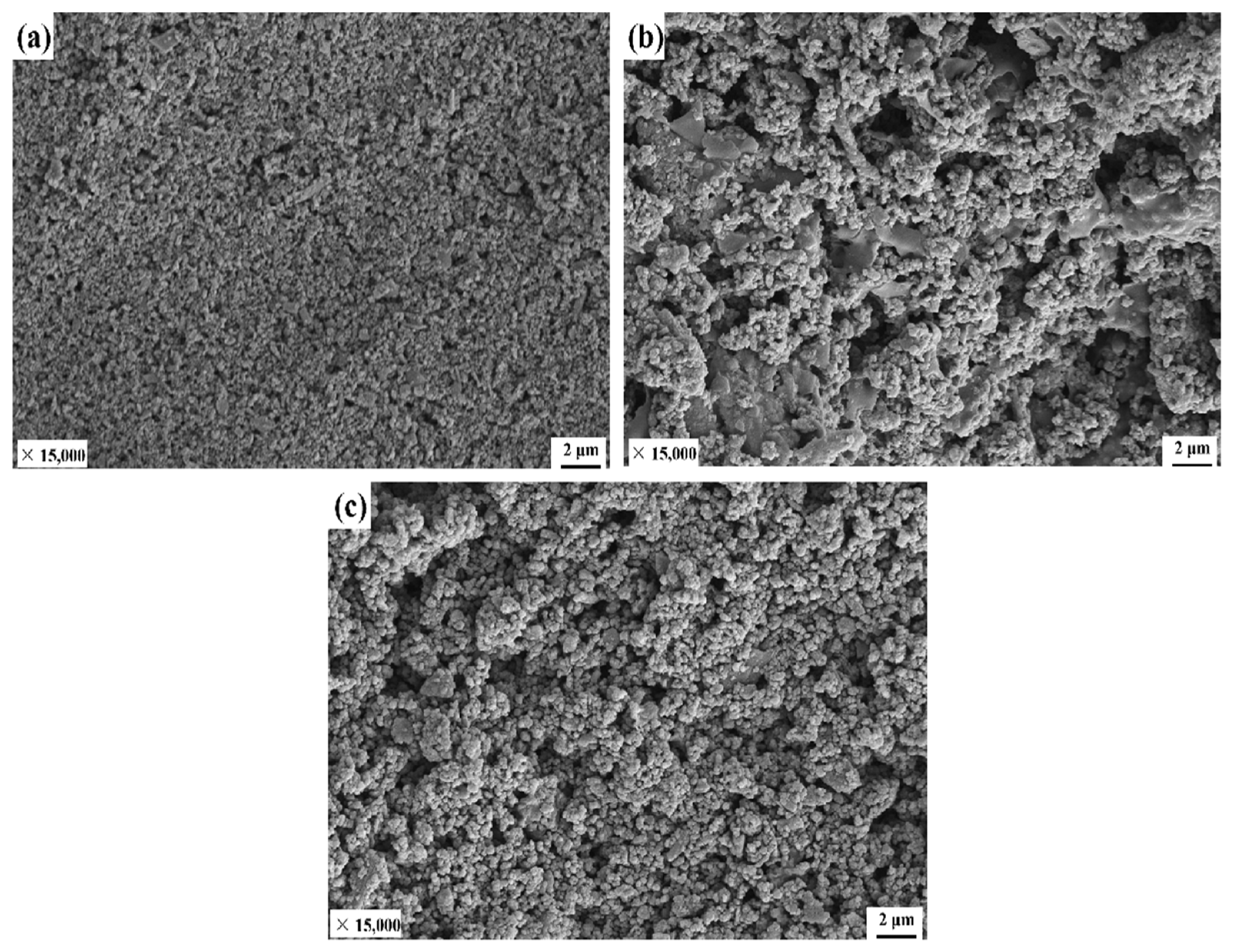

SEM images of IOT after ball milling (a) and SEM images of IOT/POS for a HDTMS amount of (b) 1.5 mmol and (c) 2.5 mmol. Image Credit: Su, Z et al., Materials

The Study

The authors have prepared a novel superhydrophobic coating using modified iron ore tailings and chloroprene rubber adhesive. This low-cost process creates exceptionally durable composite coatings.

Tailings were first prepared with ball milling and modified with HDTMS and TEOS. This produced powders that could be used in the coatings. HDTMS concentration in the powders, as well as reaction time, influences the powder’s wettability. Furthermore, the composite coating’s wettability is strongly dependent on powder concentration.

SiO2 nanoparticles irregularly stack on the iron ore tailings surface, creating a composite structure. The surface energy of the composite coating is very low, which is essential for superhydrophobic applications. This was due to the influence of the long-chain HDTMS once grafted onto the iron ore tailing mixture.

The chloroprene rubber adhesive fixes the particles in the composite iron ore tailings powder. Moreover, it strongly binds the substrate and coating. This makes the coating extremely durable and suitable for highly demanding industrial applications.

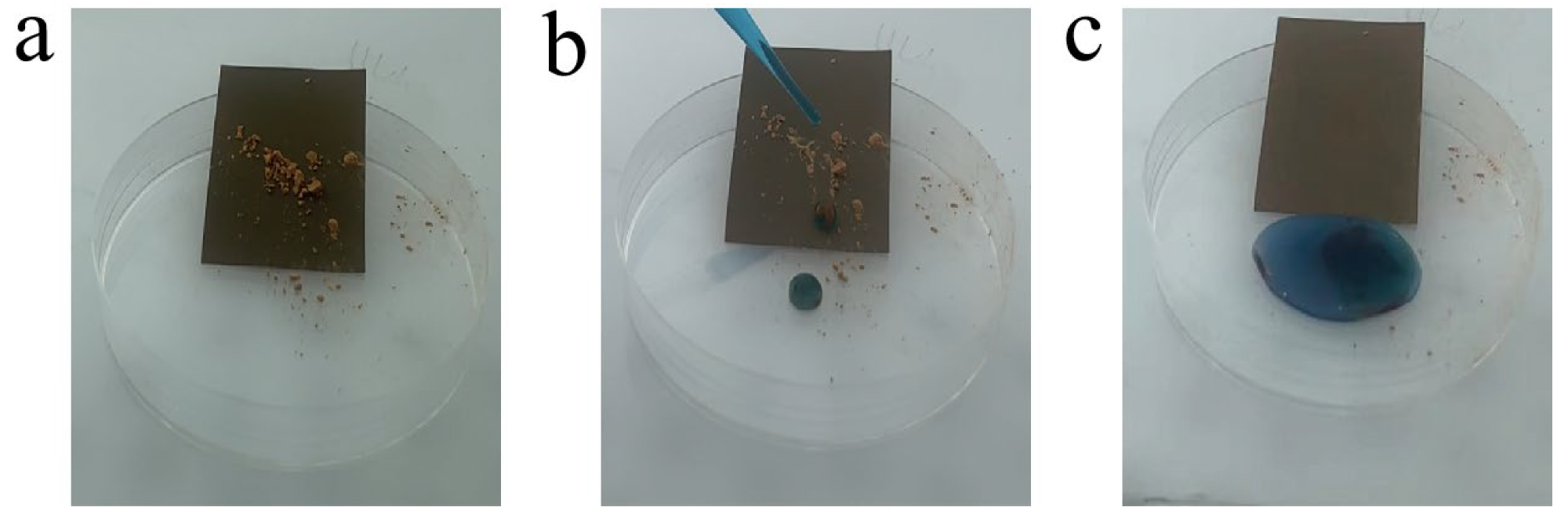

The coatings produced in the research have several advantageous properties, including superior CA values, low SA, and good self-cleaning properties.

The process of composite coating self-cleaning (a–c). Image Credit: Su, Z et al., Materials

In Summary

The authors have demonstrated a low-cost, facile, and novel process for preparing superhydrophobic coatings with enhanced durability and beneficial properties. By making use of a critical waste stream to create this value-added product, the research provides a route to improving the sustainability and circularity of several industries.

Whilst this study has focused on one type of waste material to prepare coatings, it will help future research to produce coatings from other industrial waste materials, which will help a number of industries reach their net-zero carbon commitments.

Further Reading

Su, Z et al. (2022) Preparation of Iron Ore Tailings-Based Superhydrophobic Coatings Materials 15(12) 4235 [online] mdpi.com. Available at: https://www.mdpi.com/1996-1944/15/12/4235

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.