Scientists from Romania have evaluated the use of bacteria to improve mortar in construction applications, investigating several different strains. Their findings have been published in the journal Materials.

Study: Highlighting Bacteria with Calcifying Abilities Suitable to Improve Mortar Properties. Image Credit: Kateryna Kon/Shutterstock.com

Towards Sustainable Construction Materials

The modern construction industry uses vast amounts of natural resources to provide infrastructure and buildings across the world. However, commonly used materials in construction, such as concrete, are largely unsustainable due to the carbon emissions produced during their manufacture and their use of virgin, non-renewable resources.

Improving the qualities of concrete, as well as lengthening the lifetime of structures and reducing associated costs are the main focuses of research in the construction sector currently. The increasing demand for concrete and other common construction materials and consequent environmental damage, and the need for performance enhancement has crystallized the need for alternative materials.

Bioengineering provides a route toward improving the sustainability and functional properties of cementitious materials. Amongst the various bioengineering technologies developed in recent decades, biomineralization has emerged as a suitable candidate for improving the qualities and durability of cementitious composites.

Biomineralization: An Overview

Biomineralization of calcium carbonate is caused by the induced precipitation of calcium carbonate by specific microorganisms. This process plays a key role in the cementation of natural systems such as caves, soil, and so forth. Various mechanisms can produce biomineralized materials, such as photosynthesis, methane oxidation, urea hydrolysis, and sulfate reduction.

Urea hydrolysis is caused by the catalyzation of urea by the enzyme urease, which is secreted by microorganisms. The simple mechanism of urea hydrolysis involves the absorption of environmental calcium ions by negative charged bacterial cells, which then use bacterial urease to hydrolyze urea, producing NH4+ and CO3-2, with CO3-2then combined with calcium ions to produce calcium carbonate crystals.

Once urea hydrolysis is completed, calcium carbonate crystals surround the bacterial cells. The mineralization rate is related to the rate of urea hydrolysis. Due to its simplicity and efficiency, urea hydrolysis biomineralization has been applied to several different construction materials and technologies. The main factors which influence this process include bacterial genotype, cell concentration, nutritional medium composition, and calcium ion availability.

Several studies on microbially induced calcium carbonate precipitation have evaluated several bacterial species. These include Sporosarcinapasteurii, B. subtilis, B. megaterium, and Synechocococcus sp. Pseudomonas aeruginosa, a nitrate-reducing bacteria, has also been studied. Amongst the various bacterial species studied, Bacillus and Sporosarcina have emerged as suitable candidates.

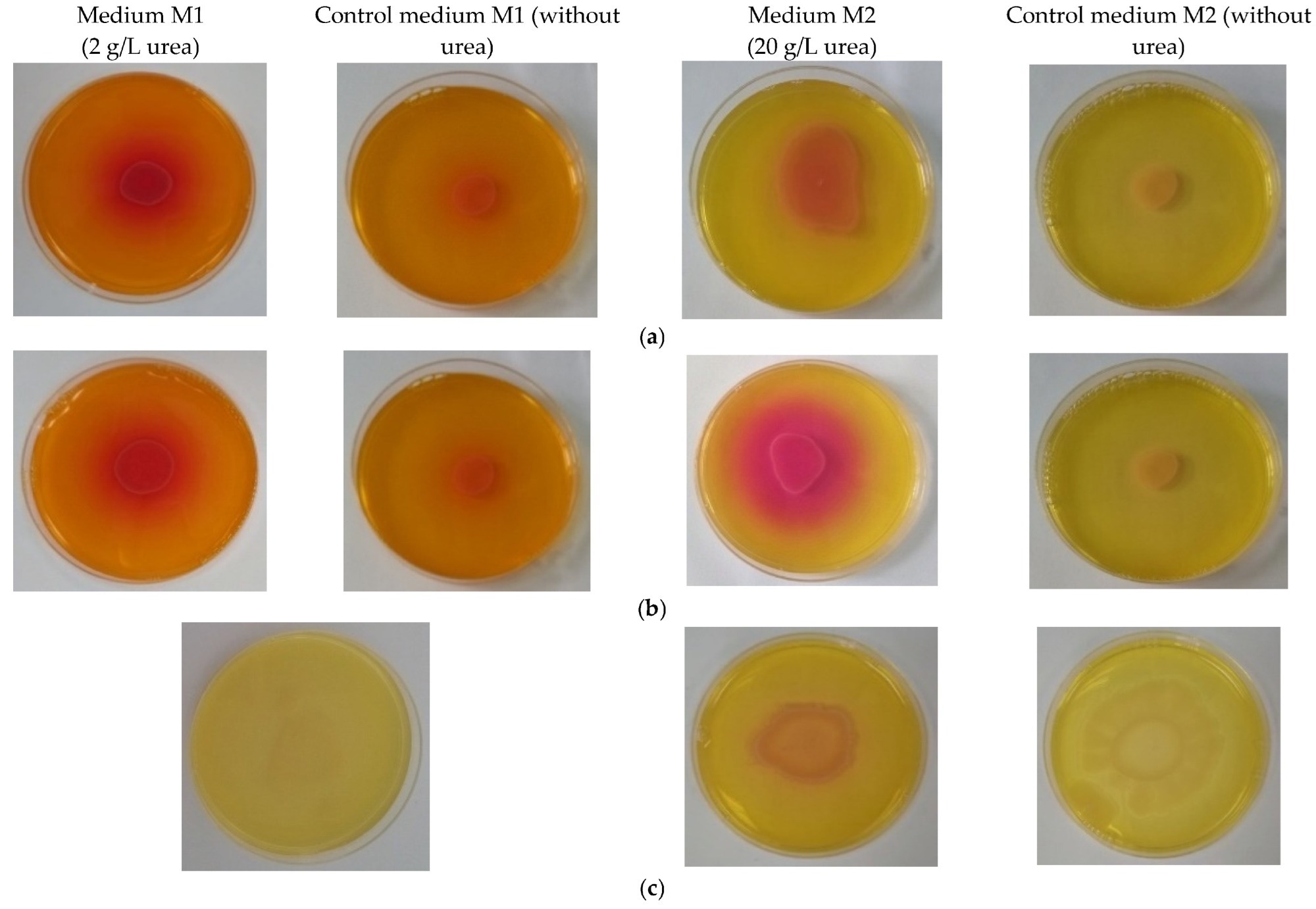

Ureolytic activity of bacterial strains in Petri plates on solid media of different compositions: (a) B. licheniformis on media M1, M2 and their corresponding controls (without urea and calcium ions); (b) B. subtilis on media M1, M2 and their corresponding controls (without urea and calcium ions); (c) B. amyloliquefaciens on media M1, M2 and their corresponding controls (without urea and calcium ions). Image Credit: Răut, I., et al., Materials

The Paper

By investigating the suitability of biomineralization for manufacturing sustainable mortars with enhanced properties, the paper provides key information which will facilitate a route toward sustainable, bioengineered concrete production.

The main objectives of the paper are to evaluate the abilities of several bacterial strains for calcification under proper culture conditions and to evaluate how microbial-induced calcite precipitation can influence and improve the physiomechanical properties of cementitious mortar.

Four different bacterial species were selected by the authors and cultivated in a nutritional medium, including calcium ions and urea. The species investigated were B. amyloliquefaciens 1014, B. subtilis ATTC 6633, P. putida LMG 2257, and IB. licheniformis 1015. For the control medium, a urease-selective medium that did not include urea was selected.

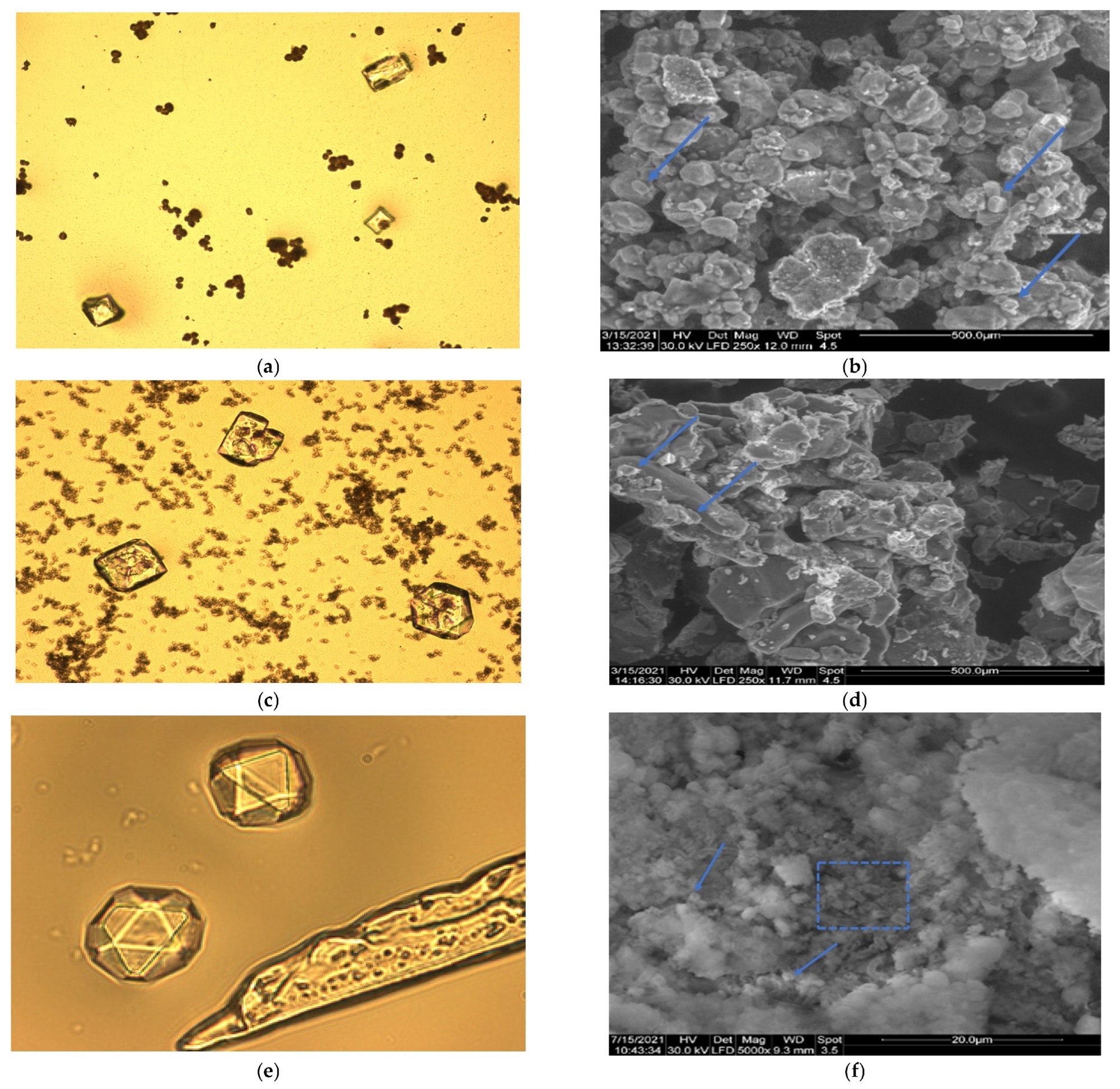

Qualitative ureolytic activity tests were performed by the authors, with techniques such as FTIR, SEM, XRD, and TGA used to analyze and evaluate the bacterial species’ calcium carbonate precipitates and, therefore, suitability. Morphological analysis was conducted using microscopic techniques. The properties of prepared biomineralized mortar samples were evaluated.

Microscopic investigations of deposits obtained from bacteria cultured on medium with urea and calcium ions. On left, optical microscopy is shown, and on the right, SEM analysis, as: (a) Spores and crystals carbonate from Bacillus amyloliquefaciens (20×); (b) SEM analysis of pellet from Bacillus amyloliquefaciens (250×); (c) Spores and crystals carbonate from Bacillus licheniformis (20×); (d) SEM analysis of pellet from Bacillus licheniformis (250×); (e) Crystals carbonate and germens of crystallization at Bacillus subtilis (100×); (f) SEM analysis of deposit from Bacillus subtilis (5000×). Dotted square-bacterial cells; arrow—calcium carbonate crystals. Image Credit: Răut, I., et al., Materials

Research Findings and Conclusions

The experimental results and analysis revealed that Bacillus subtilis is a promising candidate for preparing biomineralized mortar for use in cementitious materials and sustainable concrete production. This non-pathogenic bacterium can adequately mediate microbial-induced calcite precipitation.

Mortars prepared with Bacillus subtilis displayed adequate property enhancements, namely compressive strength and water absorption, two key properties required of cementitious materials for use in the construction industry. There exists the potential to further improve these properties to reach comparable values with currently reported materials.

The authors have noted that there are still some research directions that could prove beneficial to the study of biomineralized cementitious composites, and the bacterial strains evaluated in the paper. The optimal bacterial cell dosage in mortar mixtures should be further evaluated, as cell concentration has a significant effect on the material’s water absorption and compressive strength.

Another potential research direction is the evaluation of the durability and longevity of bacteria in mortars to improve their application. Finally, the authors have stated that the results contained in the new paper can be used to design experimental protocols for future research into using bacteria to improve the properties and durability of alternative bioengineered mortars for construction.

Further Reading

Răut, I., et al. (2022) Highlighting Bacteria with Calcifying Abilities Suitable to Improve Mortar Properties. Materials, 15(20), P. 7259 [online] mdpi.com. Available at: https://www.mdpi.com/1996-1944/15/20/7259

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.