Image Credit: Tokyo Institute of Technology.

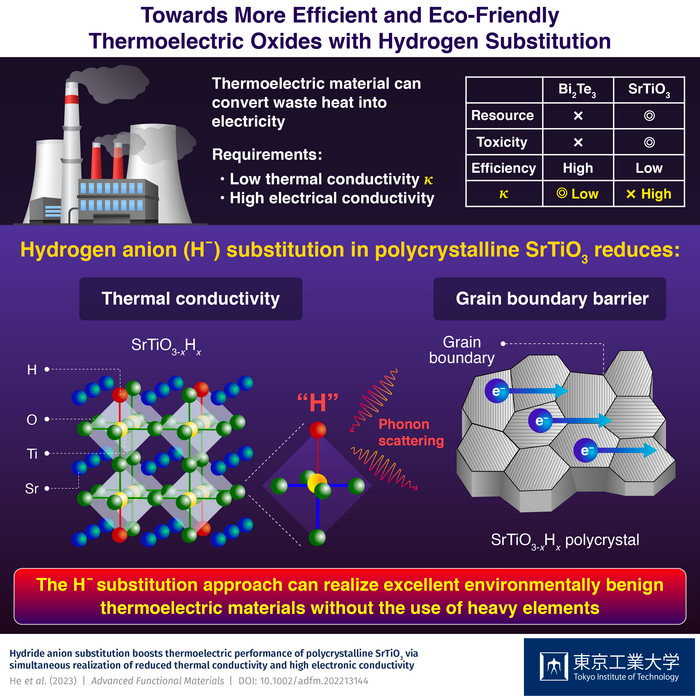

Transition metal oxides centered on platforms like SrTiO3 have been developed to address these concerns as a more cost-effective and environmentally friendly alternative.

Their ZT is usually restricted by a high thermal conductivity (κ), because for a high κ, the temperature across the material will become uniform more rapidly, and the lowered temperature difference—the key driver behind the thermoelectric conversion—induces electric power generation to reduce as well.

In light of this, a study group led by Associate Professor Takayoshi Katase of the Tokyo Institute of Technology (Tokyo Tech) in Japan recently developed a new method for decreasing and improving the performance of SrTiO3 through hydrogen substitution.

Traditionally, using light elements is anticipated to accelerate the κ arising from lattice vibration (κlat), contributing to the adoption of heavy elements to decrease the κlat. In contrast, the scientists revealed in their research published in Advanced Functional Materials that, by adding a light element, specifically hydrogen, the κlat of SrTiO3 could be lowered to less than half its initial value.

Researchers explained the factors that underlie their finding using first-principles calculations, which demonstrated that replacing a portion of the oxygen anions (O−) with hydrogen anions (H−), producing compounds of the form SrTiO3−xHx, yields a mixture comprising a strong Ti-O bond and a weak Ti-H bond. The randomly distributed Ti-(O,H) bonds, in turn, significantly reduce κlat.

The researchers also discovered that SrTiO3−xHx polycrystals have high electron mobility comparable to single-crystal materials, with no degradation in electron conduction across grain boundaries. Based on these two phenomena, the SrTiO3−xHx polycrystal exhibits low heat conductivity and high electrical output power, resulting in higher thermoelectric conversion efficiency.

Ultimately, these findings may pave the way for novel approaches to producing next-generation thermoelectric materials. “In future, the hydrogen substitution approach would realize excellent environmentally benign thermoelectric materials that do not require the use of heavy elements,” concludes Dr Katase.

Continued research in this area leads to the broad implementation of thermoelectric conversion technology so that even waste heat is not wasted.

Journal Reference

He, X., et al. (2023) Hydride Anion Substitution Boosts Thermoelectric Performance of Polycrystalline SrTiO3 via Simultaneous Realization of Reduced Thermal Conductivity and High Electronic Conductivity. Advanced Functional Materials. doi.org/10.1002/adfm.202213144.