Metal-organic frameworks (MOFs) are special materials with nano-sized pores. These pores make MOFs unique because they have an incredibly large inside surface area. This quality makes MOFs very useful for many things, like separating chemicals and gases, imitating DNA, making hydrogen, and cleaning water by taking out heavy metals, fluoride particles, and even gold.

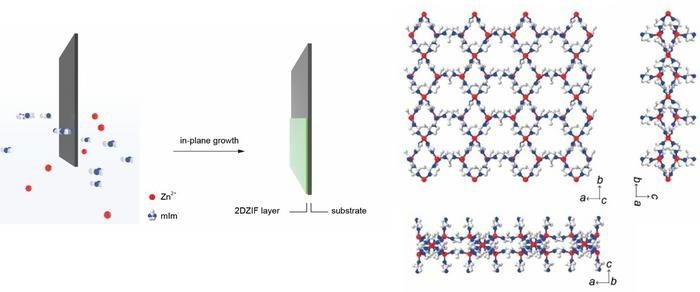

Schematic showing straightforward crystallization of 2d ZIF film by dipping a substrate in ultra dilute precursor solution at room temperature (left). Right: Crystal structure of 2d ZIF where white, blue, and red atoms represent carbon, nitrogen, and zinc atoms. Image Credit: Qi Liu, EPFL.

Schematic showing straightforward crystallization of 2d ZIF film by dipping a substrate in ultra dilute precursor solution at room temperature (left). Right: Crystal structure of 2d ZIF where white, blue, and red atoms represent carbon, nitrogen, and zinc atoms. Image Credit: Qi Liu, EPFL.

In the world of gas separation, MOFs are especially exciting because they can separate hydrogen from nitrogen. This separation is crucial for clean energy, efficient fuel cells, making ammonia, and various industries. Separating hydrogen from nitrogen is also good for the environment, which helps make technology and industry more sustainable.

A group of researchers, led by Professor Kumar Varoon Agrawal from EPFL's School of Basic Sciences, has created an incredibly thin film of MOF that can separate hydrogen from nitrogen exceptionally well. These researchers worked with a type of MOF called zeolitic imidazolate frameworks (ZIFs), known for their potential in tasks like separating molecules and sensing things.

To create these films, the researchers used a clever method to grow crystals. They used a precise alignment technique with extremely diluted mixtures of building blocks on a crystalline base. By carefully controlling the concentrations of these building blocks and how they interact with the base, the team managed to prevent the film from growing too thick, a common problem when making thin films.

Their approach was successful. In a short time and at room temperature, the researchers managed to create 2D ZIF films that were incredibly thin – just one structural unit, measuring a mere 2 nm. They demonstrated that this method can be scaled up to make films covering hundreds of square centimeters.

This achievement surpasses traditional methods, which could only produce ZIF films up to 50 nm thick, limiting their widespread use.

The ZIF film they created has a unique structure; it is only a nanometer thick and has a regular pattern of six-membered zinc-imidazolate coordination rings, which are excellent at filtering out hydrogen.

This allows for an exceptional combination of hydrogen flux and selectivity, holding immense potential for highly efficient gas-separation applications.

Kumar Varoon Agrawal, Professor, School of Basic Sciences, École Polytechnique Fédérale de Lausanne

Journal Reference:

Liu, Q., et al. (2023). Unit-cell-thick zeolitic imidazolate framework films for membrane application. Nature Materials. doi.org/10.1038/s41563-023-01669-z.