Elkem will showcase silicones parts printed with the AMSil™ & AMSil SILBIONE™ range, an innovative technology recognized as a winner of R&D 100 award, at the upcoming Formnext show in Germany from November 7th to November 10th 2023.

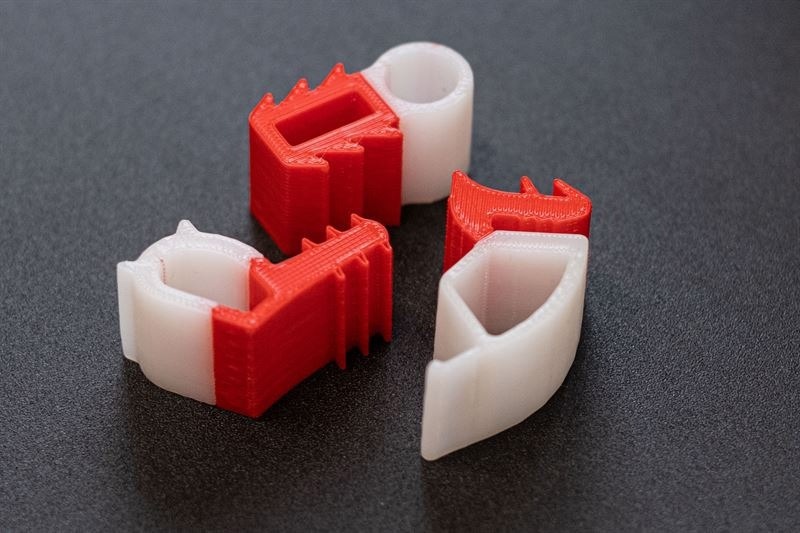

Elkem AM-3DP 2grades Silicones printed parts. Image Credit: Elkem

Elkem AM-3DP 2grades Silicones printed parts. Image Credit: Elkem

This range enables the production of functional parts from genuine 100% silicone elastomers by Additive Manufacturing/3D Printing using the LDM technology. These products address the megatrends challenges and offer two series:

- AMSil™ 20000 series for industrial applications (aerospace, automotive, electronics, equipment etc.). The AMSil™ series allows the use of silicones in digital, connected and distributed manufacturing (Industry 4.0) for a more efficient and sustainable production method.

- AMSil™ Silbione™ 24000 series for restricted medical applications. Elkem Silicones aims to improve the quality of life of the ageing population by combining the performance, durability and biocompatibility of silicones with Additive Manufacturing/3D Printing.

Thanks to their specific formulations, these products can now be used in food-grade applications as well as in medical and industrial applications. Combining different grades of silicone and also multi-material combinations give an insight into the possibilities for improving performance with Additive Manufacturing/3D Printing. Next step technologies will be displayed at Elkem booth as examples of future developments with silicone in the field of Additive Manufacturing/3D Printing.

Examples of printed silicone parts of complex shapes and specific geometries using the unique support material, the AMSil™ 92100 series, together with the AMSil™ and AMSil™ Silbione™ series, demonstrate the potential for innovations with Additive Manufacturing/3D Printing.

These innovations demonstrate Elkem commitment to Additive Manufacturing/3D Printing and its potential to contribute to a more sustainable economy in the future. By enabling Additive Manufacturing/3D Printing to scale up as part of the factory of the future through digital manufacturing, Elkem helps customers create innovative, profitable and sustainable solutions that reduce environmental impact by minimizing waste and saving on transport and storage costs, two major factors in the overall carbon footprint of end-products.

To learn more about Elkem portfolio for Additive Manufacturing/3D Printing, visit its booth F 91 in hall 12.1. Meet the team and discover the full range of silicone solutions for Additive Manufacturing/3D Printing by sharing your experiences and requirements for the latest technological advances with Elkem experts.