As EV battery manufacturing technologies evolve, from coated film to solid-state cells, the industry is facing new contamination challenges that existing processes aren’t equipped to handle. According to Meech International, a global expert in static control and surface cleaning technologies, the shift towards more complex, multi-stage production techniques is increasing the potential for contamination from both machinery and the environment, even in dry room or cleanroom conditions.

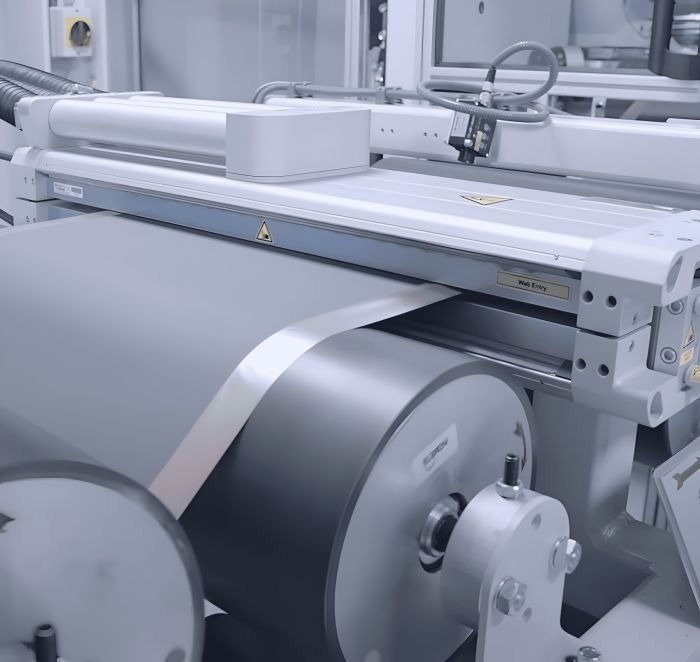

OEM EV Battery Pilot Line using CYCLEAN™ non-contact web cleaner. Image Credit: Meech International

OEM EV Battery Pilot Line using CYCLEAN™ non-contact web cleaner. Image Credit: Meech International

These new battery chemistries often require multiple stages of coating, cutting and handling. For example, solid-state electrode production involves coating a base material with active components, followed by a second layer of insulating material. This layered structure offers enhanced performance but also introduces more friction-heavy processing steps, each of which risks introducing particulate contamination. The presence of static charge further exacerbates this, as it causes particles to be attracted to sensitive surfaces, where they can become embedded and difficult to remove.

“Process engineers are under pressure to optimise both the chemistry and efficiency of these emerging technologies,” explains Ian Atkinson, board member and sales director at Meech International. “But they’re not always specialists in static and contamination control—so problems can occur before they're even recognized.”

Contamination at sub-micron levels can affect stacking accuracy, reduce cycle life, and even compromise safety. In some cases, electrostatic charge builds up on insulating materials or carrier films, leading to sticking, misalignment, and reduced line speeds in automated processes.

Meech recommends integrating advanced surface cleaning and static control measures as early as possible in the design and production process. For example, technologies that use airflow dynamics to extract particles below 1 μm without touching the substrate are already being adopted by major manufacturers.

These systems maintain pristine surface conditions throughout high-speed production lines while minimizing waste and eliminating the need for inconsistent or manual interventions.

Meech will be showcasing its portfolio of contamination control technologies at The Battery Show Europe 2025 (3–5 June, Messe Stuttgart, Hall 10 Stand H100), where its experts will be available to advise on how best to incorporate these solutions into new and existing battery production lines.