Reviewed by Lexie CornerJun 9 2025

Researchers at Pennsylvania State University have developed a new material using plant-based cellulose and milk protein. Their findings were published in the Journal of Colloid and Interface Science.

Milk protein and cellulose derived from plants can be electrospun into thin fibers for use in mats that could be used for biodegradable and edible food packaging, according to a new study by researchers at Penn State. Image Credit: Penn State

Milk protein and cellulose derived from plants can be electrospun into thin fibers for use in mats that could be used for biodegradable and edible food packaging, according to a new study by researchers at Penn State. Image Credit: Penn State

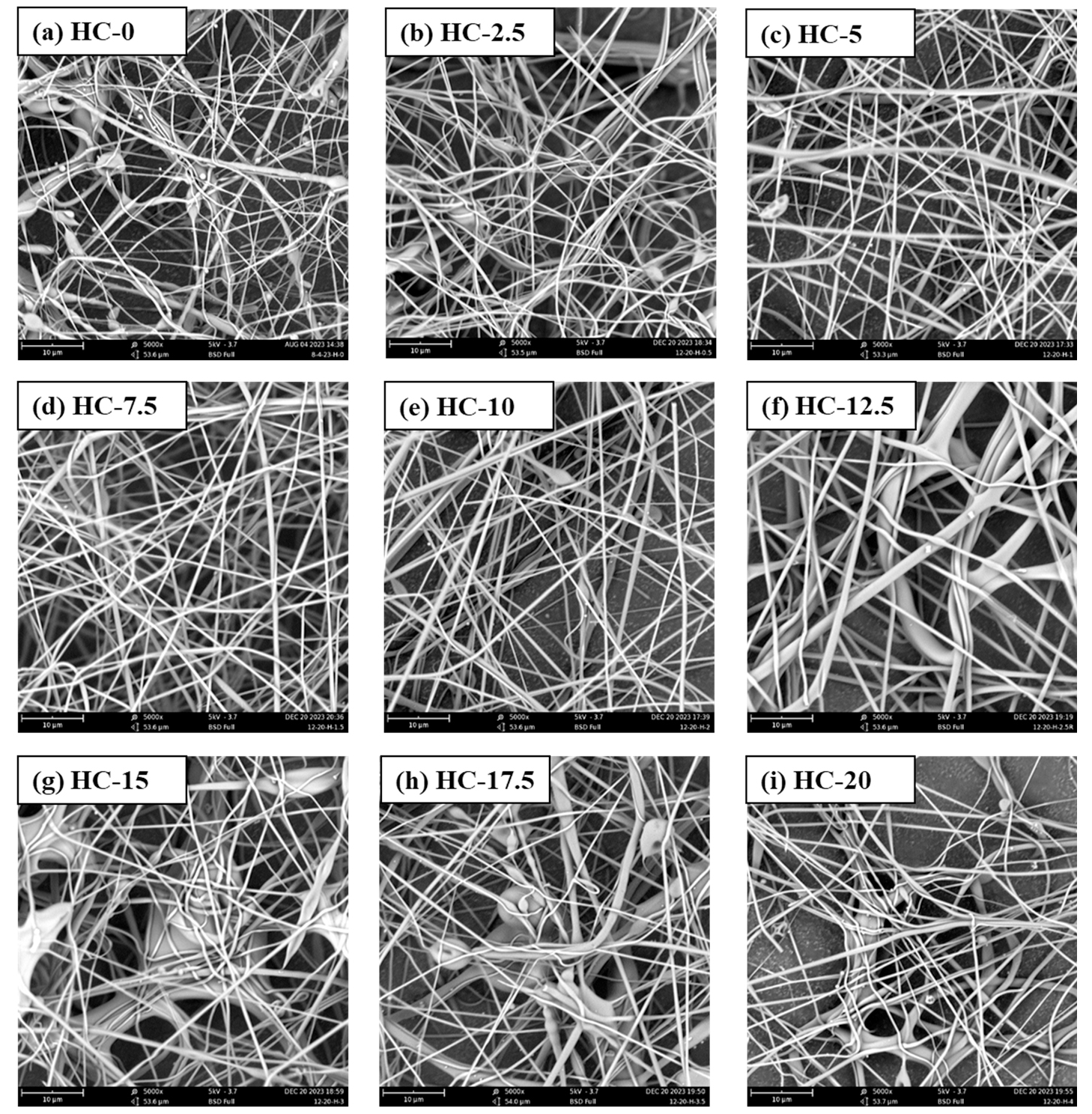

The team combined the milk protein casein with hydroxypropyl methylcellulose (also called hypromellose), a plant-derived material. They used a technique called electrospinning, which applies voltage to a liquid solution. This causes the solution to form a cone shape and stretch into tiny fibers as it is ejected.

The resulting nanofibers are 1,000 times thinner than human hair. The researchers then formed these fibers into mats that could be used in various applications, including biodegradable and even edible food packaging.

In a proof-of-concept study, we demonstrated the successful fabrication of stand-alone casein-rich electrospun mats. Protein-based electrospun nanofibers are highly sought after for their potential use in tissue engineering, biomedical applications such as wound dressings, and emerging roles in edible packaging, offering sustainable food preservation and safety solutions.

Federico Harte, Team Co-Leader and Professor, Food Science, College of Agricultural Sciences, Pennsylvania State University

The researchers found that casein mixed with hypromellose could be electrospun at cellulose-to-casein ratios as high as 1:4.

The solution with a 1:12 cellulose-to-casein ratio produced fibers with the fewest beads. These fibers had thicker, uneven sections and the highest surface area, making them well-suited for use in mats.

The team also observed that under 100 % relative humidity, the fiber mats reacted readily to moisture. They transformed into translucent films, showing potential for use as food wrap.

Casein has a long history of use as a material for both food and non-food uses, explaining that the protein can enhance food textures and nutritional values, as well being used in the production of glues, paints, paper coatings, cosmetics and pharmaceuticals. This research adds to its utility by giving a new form: nanofibers.

Gregory Ziegler, Team Co-Leader and Distinguished Professor, Food Science, College of Agricultural Sciences, Pennsylvania State University

Harte noted that this study is the latest in a series of investigations on casein electrospinning. In earlier work, the research group studied electrospinning of casein alone and in combination with carrageenan. Carrageenan is a food additive derived from red seaweed and is commonly used as a thickener, stabilizer, and emulsifier in various food products.

However, the mats produced in those earlier studies contained weak and brittle nanofibers.

In the current study, the researchers explored whether adding hypromellose to casein could improve fiber strength and flexibility. Their results supported this approach.

“The idea here was to create mats based on casein, which is something that hasn't been done before. Our early efforts using casein alone clearly showed that we needed to improve the mechanical properties of the mats, and we eventually decided to add hypromellose because we thought that an interaction between casein and cellulose would optimize mechanical properties in these mats,” added Harte.

Harte also said that future research will explore possible uses for edible casein nanofibers, including food packaging and filtration.

The study’s lead author was Deepika Sharma, a postdoctoral fellow in food science. The research was funded by the National Dairy Council–Dairy Management Inc.

Journal Reference:

Sharma, D., et al. (2025). Fabrication and physicomechanical performance of casein-hydroxypropyl methylcellulose nanofibers. Journal of Colloid and Interface Science. doi.org/10.1016/j.jcis.2025.137601