|

The favourable strength to weight ratio and generally excellent mechanical properties of carbon fibre has led to its use in many aerospace, sports goods and transportation applications. Another well recognised, but less often used, property of carbon fibre is its electrical conductivity. Work in the area of electrically conductive fabrics by US company Thermion Systems International has led to the development of a proprietary carbon fibre heating fabric, which is currently being used in the aerospace industry for in-flight de-icing.

Structure of the Heating Fabric

Thermion, is a resistive heating material comprised of nickel coated non-woven carbon fabric, figure 1. Research and development has shown that coating the carbon in nickel gives the fabric an appropriate resistivity and superior corrosion resistance compared to other possible coatings. Its resistivity can be tailored by varying several parameters to suit the required application.

|

|

|

Figure 1. A SEM image of showing the nickel coated carbon fibres.

|

Although the thickness and weight of the material is dependent on the required resistivity, Thermion is nonetheless very thin and flexible, with typical thickness values of between 0.08-1.27mm. Its low thermal mass means it can deliver swift thermal cycle times in both heat up and cool down, and the flexibility of the fabric makes it suitable for relatively complex geometries. Power can be supplied to the material by attaching leads, which use either alternating or direct current, at power levels ranging from a few volts to hundreds of volts, or by inductive methods.

Aircraft Applications

Already in use for wing de-icing on the McDonnell Douglas MD-80 commercial airliner, the Thermion technology is now being tested for aircraft propeller and helicopter rotor blade de-icing applications. Incorporated into Thermion heaters, figure 2, the unique ‘self heating laminate’ technology is highly controllable and able to deliver precise levels of heat almost instantly to airfoil surfaces of wings, propellers and rotor blades.

|

|

|

Figure 2. Self heating laminate panel.

|

Industrial and Consumer Heaters

The industrial and consumer heaters are made from a mass produced laminate of Thermion in a broad variety of thermoplastics such as PEEK, PEI and PU, and thermosets such as epoxy. Secondary lamination in elastomeric materials has also been performed. The lamination process provides chemical and environmental resistance, and glass fibre non-woven mats may be incorporated for extra electrical insulation and for improved mechanical properties. In most cases the temperature capacity of the heater is only restricted by the temperature capacity of the material within which it is laminated.

Advantages over other Heating Elements

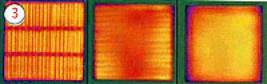

The benefits of Thermion compared with other heating elements, such as wire or foil, include even heating, damage tolerance, being lightweight and having low thermal inertia. Figure 3 shows the thermal signatures produced by foil, wire and Thermion heaters respectively. Unlike foil or wire heaters, these heaters do not become inoperative as a result of single small local failures. This is a particularly important property in aerospace applications, in which electrothermal heaters are used for wing, propeller and rotor blade de-icing. The ease of installation either before or after manufacture, FOD (foreign object damage) tolerance, high controllability and ability to deliver precise levels of heat to specific areas means the heaters are ideally suited for use as part or all of an ice protection system. The French Air Force is currently testing the heaters for effective in-flight de-icing of aircraft, and application development projects are also underway with a number of major aerospace companies such as Boeing, GKN (Aerospace Composite Technologies), Hamilton Sundstrand, British Aerospace and Ratier-Figeac.

|

|

|

Figure 3. Thermal signatures produced by (from left) foil, wire and Thermion heaters (right).

|

Future Applications

Thermion Systems International's European affiliate, Thermion Systems Europe, based in Luton, UK, is currently focusing on the design, development and large scale manufacture of industrial and commercial heaters for a number of potential applications in which the heaters are being considered as superior, low cost alternatives to existing technology, including:

- Diverse heating applications in trucks and automobiles

- Heaters to prevent condensation during shut down in heat producing mechanisms, such as electric ovens or motors

- Heating of moulds during manufacturing processes specific heating applications in domestic appliances, laboratory and hospital equipment

- Heating of containers for transport and storage of liquids and semi-solids

- Diverse heating requirements in the processing industries

Limitations of the Technology

While solving many of the limitations of existing heating elements, the temperature capability of the heaters is restricted by the temperature limitations of the material in which it is encapsulated. Easily processable polymers that can cope with temperatures of up to 200°C are available, but the choice of encapsulant becomes restricted when temperatures above this are required. As part of an ongoing programme of research, work is currently underway, investigating the incorporation of the technology into high temperature materials such as ceramics so that the full temperature range of the heating capability of Thermion may be realised.

|