Fat extractions are a crucial part of food testing and safety. They are key to accurately calculating nutrition facts and providing quality assurance.

Image Credit: CEM Corporation

Fat extractions are conventionally performed utilizing acid prehydrolysis and the Soxhlet method, which is tedious, manual and time-intensive. Therefore, faster and more automated methods are in demand.

The EDGE®, an automated extraction system, was used for the extraction of fat from different food samples utilizing acid prehydrolysis protocol prior to extraction – the direct extraction of each food was also accomplished. Foods considered low, medium and high fat were all extracted with exceptional recoveries and RSDs.

The EDGE is the optimal choice for food laboratories that need to acquire intact fat extracts and wish to integrate automation into their workflow.

Introduction

Fat extractions are an essential part of food formulation for food manufacturers. Manufacturers also test a food’s fat extracts to guarantee the freshness and quality of their products. As consumers are increasingly educated in the content and quality of the foods they consume, precise reporting of nutrition facts, particularly fat, is vital.

In the manufacturing process, the quickest and most precise testing methods are always coveted. Typically, food samples should be prehydrolyzed utilizing acid in order to liberate bound fat for extraction.

Subsequently, the majority of fat extracts are acquired from prehydrolyzed samples using the Soxhlet method, which is a labor-intensive, manual and time-consuming method that requires several hundred milliliters of solvent.

The EDGE is an automated extraction system that facilitates the intact extraction of fat. The EDGE uses Q-Cup® technology to extract, filter and cool the fat extracts from a number of food samples.

In this application note, numerous foods with various amounts of fat, fluctuating from low-fat to high-fat, were extracted utilizing the EDGE with and without prehydrolysis.

The conventional Soxhlet extraction method was also performed on these matrices for a comparison of results. The EDGE results were comparable with very good RSD values. Thus, the EDGE is the optimal choice for a food laboratory intending on extracting fat from their food samples as an intact extract method.

Materials and Methods

Reagents

Food samples were bought from a local grocery store. Hydrochloric acid (37%) was acquired via Fisher Scientific. Petroleum ether and 3-mm glass beads were supplied by VWR.

Sample Preparation - EDGE Extraction Without Acid Hydrolysis

Using a food blender, each food sample was homogenized. Then, the homogenized food, excluding the raw eggs, was weighed (the sample size is displayed in Table 1 on page 3) immediately into a Q-Cup holding the S1 Q-Disc® stack (C9+G1+C9 sandwich).

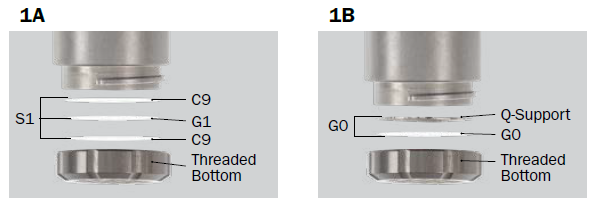

A Q-Screen was positioned on top of the sample using a Q-Screen tool. The Q-Cup configuration can be seen in Figure 1A.

Using petroleum ether for extraction, the sample was transferred into preweighed 60 mL vials holding three 3-mm glass beads to avoid bumping during evaporation. Extraction of the samples was conducted using the EDGE method for fat from non-hydrolyzed samples. Each cycle was collected separately.

Figure 1. Positioning of the G1 and C9 Q-Discs, used in the extraction of the non-hydrolyzed samples (A) and the positioning of the Q-Support and G0 Q-Disc, a combination called G0 used in the extraction of the hydrolyzed samples (B). Image Credit: CEM Corporation

EDGE Method for Fat from NonHydrolyzed Samples

Q-Disc: S1 Q-Disc® stack (C9+G1+C9 sandwich)

Cycle 1:

- Extraction Solvent: Petroleum Ether

- Top Add: 30 mL

- Bottom Add: 0 mL

- Rinse: 0 mL

- Temperature: 140 °C

- Hold Time: 05:00 (mm:ss)

Cycle 2:

- Extraction Solvent: Petroleum Ether

- Top Add: 30 mL

- Bottom Add: 0 mL

- Rinse: 0 mL

- Temperature: 140 °C

- Hold Time: 05:00 (mm:ss)

Wash:

- Wash Solvent: Petroleum Ether

- Volume: 30 mL

- Temperature: 30 °C

- Hold: 00:15 (mm:ss)

The resulting extracts were evaporated to a steady weight utilizing a Q-Dry™ solvent evaporator at 40 °C and set in an oven at 100 °C for 30 minutes. The extraction vials were left to cool to room temperature and later weighed.

The fat yield was established by subtracting the weight of the vial and beads from the weight of the dried extract remaining in the vial.

Sample Preparation - EDGE Extraction with Acid Hydrolysis

Using a food blender, each food sample was homogenized. The homogenized samples were weighed into glass beakers (at the sample size indicated in Table 1). A volume of 45 mL of boiling water and 55 mL of 8 M HCl was introduced to each sample.

The mixture and sample were stirred using a glass stir rod. The beaker was boiled for one hour on a hot plate after being covered with a watch glass.

Once the boiling process was completed, the sample was collected using a Whatman Grade 1 filter carefully positioned inside a plastic funnel. The filtration of the sample was run with natural gravity. The beaker containing the sample was rinsed with water to ensure the complete transfer of the sample.

Using 100 mL of water, the filters were rinsed and then oven-dried for one hour at 100 °C. The filters were then fixed into a Q-Cup containing a Q-Support™, bedded onto a G0 Q-Disc. This configuration, referred to as G0, is shown in Figure 1B.

A Q-Screen was positioned immediately on top of the sample utilizing the Q-Screen tool to ensure the entire sample remained submerged below the level of the solvent level.

Extraction of the samples was conducted with the EDGE method for fat of hydrolyzed samples. The samples were extracted into preweighed 60 mL vials holding three 3-mm glass beads to restrict any bumping during evaporation. Each cycle was collected separately.

EDGE Method for Fat of Hydrolyzed Samples

Q-Disc: G0

Cycle 1:

- Extraction Solvent: Petroleum Ether

- Top Add: 30 mL

- Bottom Add: 0 mL

- Rinse: 0 mL

- Temperature: 140 °C

- Hold Time: 05:00 (mm:ss)

Cycle 2:

- Extraction Solvent: Petroleum Ether

- Top Add: 30 mL

- Bottom Add: 0 mL

- Rinse: 0 mL

- Temperature: 140 °C

- Hold Time: 05:00 (mm:ss)

Wash:

- Wash Solvent: Petroleum Ether

- Volume: 30 mL

- Temperature: 30 °C

- Hold: 15 s

The resulting extracts were evaporated to a steady weight, with the help of a Q-Dry solvent evaporator at 40 °C and then slid into an oven at 100 °C for 30 minutes. The extraction vials were left to cool at room temperature and were then weighed.

The fat yield was established by subtracting the weight of the vial and beads from the weight of the dried extract that remained in the vial.

Results

For each of the six food types, Soxhlet extractions were conducted to acquire the fat percentage utilizing the AOAC methods for each matrix, as shown in Table 1. These fat values were deemed to be the reference values for each food.

Table 1. Sample Size for Each Food Matrix. Source: CEM Corporation

| Matrix |

Sample Size (g) |

| Raw Eggs |

3 |

| Coconut Flour |

2 |

| Nutella |

1 |

| Chocolate Bar |

2 |

| Hazelnut Paste |

1 |

| Peanut Butter |

1 |

Extraction of the fat from each matrix, except for that of the raw eggs, was completed using only the EDGE with no prehydrolysis. The recoveries are displayed in Table 2.

Table 2. Fat Recoveries for Soxhlet Extraction, EDGE Extraction, and Prehydroylzed EDGE Extraction. Source: CEM Corporation

| |

Soxhlet

Method |

Soxhlet

Extraction

(% Fat) |

EDGE

Extraction

(% Fat) |

RSD

(%) |

Recovery

(%) |

Prehydrolyzed

EDGE

Extraction

(% Fat) |

RSD

(%) |

Recovery

(%) |

Raw

Eggs |

AOAC 925.32 |

9.4 |

n/a |

n/a |

n/a |

9.4 |

0.1 |

100.0 |

| Coconut Flour |

AOAC 922.06 |

13.3 |

13.2 |

0.5 |

99.2 |

13.8 |

0.3 |

103.8 |

| Nutella |

AOAC 922.06 |

31.3 |

30.1 |

0.7 |

96.2 |

30.6 |

0.9 |

97.8 |

| Chocolate Bar |

AOAC 963.15 |

29.2 |

28.7 |

0.6 |

98.3 |

27.7 |

0.1 |

94.9 |

| Hazelnut Paste |

AOAC 948.22 |

71.5 |

72.2 |

2.4 |

101.0 |

69.5 |

0.2 |

97.2 |

| Peanut Butter |

AOAC 948.22 |

51.8 |

49.8 |

0.8 |

96.1 |

50.2 |

2.8 |

96.9 |

The recoveries ranged from 96-101%, which indicates superb recoveries, and the RSD values were below 2.4%, demonstrating excellent repeatability. However, the fat was not extracted from raw eggs without hydrolysis due to the fact the temperature needed for fat extraction exceeds the minimum temperature used to cook an egg, which is 65 °C.

Hydrolysis is necessary to extract fat from eggs. Additionally, all six matrices were prehydrolyzed before fat extraction was performed. The final recoveries are shown in Table 2. They range from 95-104%, demonstrating that the recoveries were an ideal model.

Furthermore, the range of the RSD values varied from 0.1-2.8%, indicating very good repeatability.

Conclusion

The EDGE was effectively used alone and in conjunction with acid prehydrolysis to successfully extract the fat from different food matrices with outstanding recoveries and RSDs for both methods. The EDGE extracted, cooled and gathered the fat extracts in under 15 minutes.

Foods considered to be low-, medium-, and high-in-fat were all extracted, clearly demonstrating that this is a dynamic method that can be utilized for a wide range of matrices.

Additionally, the fat extract acquired from the EDGE was intact, facilitating further analysis. The EDGE offers an option for fat extractions using prehydrolysis methods and a technique not requiring hydrolysis, making it a versatile tool that satisfies the needs of fat extraction laboratories.

This information has been sourced, reviewed and adapted from materials provided by CEM Corporation.

For more information on this source, please visit CEM Corporation.