Oct 26 2020

In this article, AZoM, talks to Dr. Thomas Fries, Founder and CEO of FRT GmbH, about the applications of both defect inspection and metrology.

Please could you give our readers an overview of FRT Metrology and the services you offer?

FRT offers multi-sensor optical metrology equipment on a stable 3rd generation hardware platform with in house software based on a 25 years background in developing metrology solutions for R&D and production.

What are the applications of defect inspection and metrology? Which types of industries generally use FRT Metrology’s products?

Our major target industries are automotive, medical technologies, mechanical engineering, and all kinds of wafer applications. This means different materials, e.g. silicon or compound semiconductors, as well as all steps from R&D through the manufacturing process, in detail bare wafers to front end to back end to the final device.

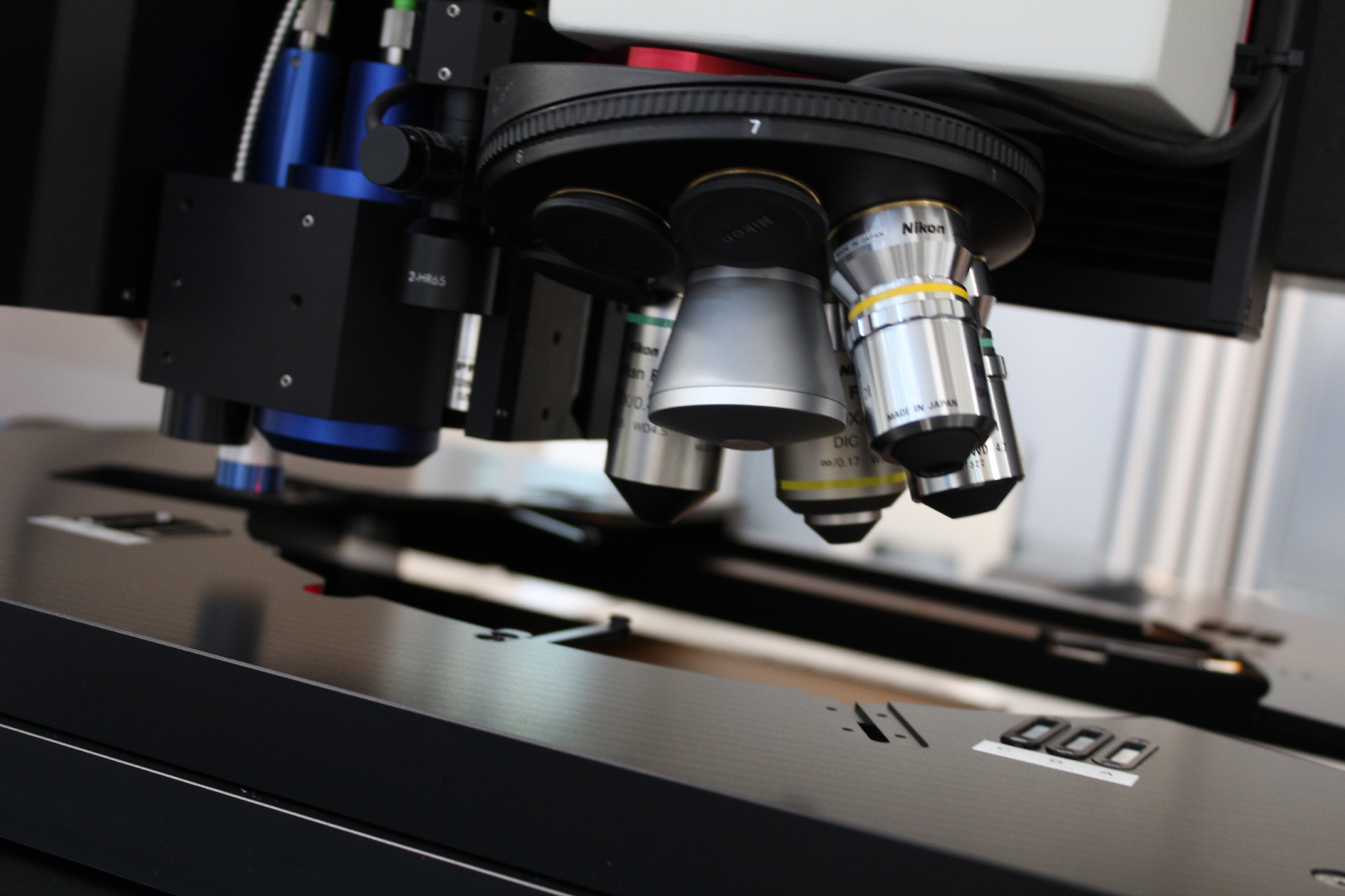

Multi-sensor setup. Image Credit: FRT

The metrology applications are all kinds of topography measurements (roughness, step height, vias, trenches), shape measurements (total thickness variation), or film thickness measurements (coating, stack thickness). Defect inspection covers macro inspection (scratches on the wafer) as well as high-resolution feature inspection on single dies.

How does FRT Metrology help users to automate their metrology tasks?

All FRT tools come with high-performance automation software allowing for free recipe creation for complex multi-sensor measurements and even hybrid metrology solutions. With our broad range of automation hardware, like wafer handling, pre-alignment, etc., the metrology tool can be fully integrated into automated wafer manufacturing lines. With our well known modular concept in hardware and software, we provide maximum flexibility for our customers.

Could you tell us how FRT Metrology’s new tool performs defect inspection and metrology in one platform?

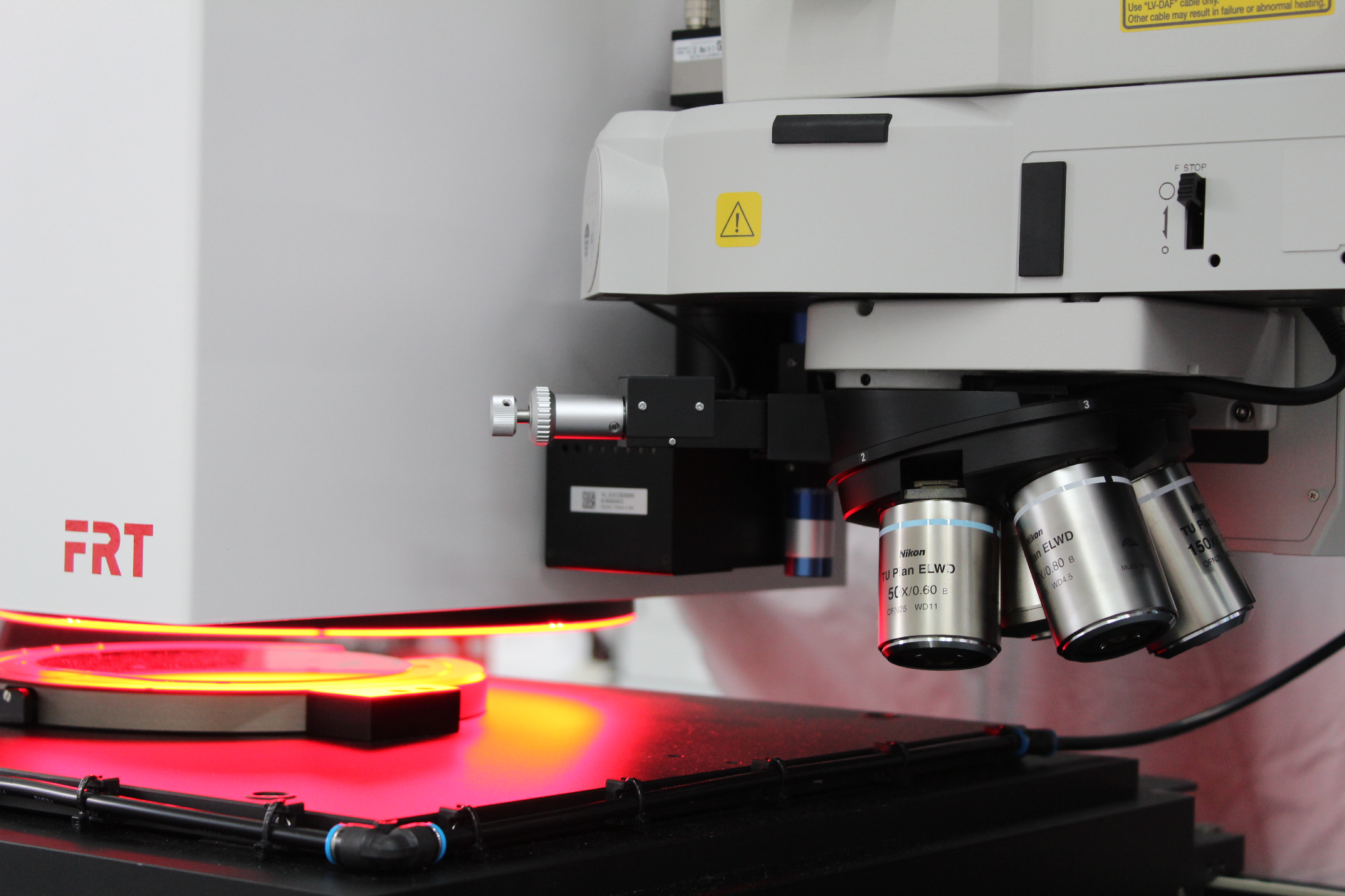

The history of our defect inspection solutions comes directly from our customer's demands. Being happy with the flexible and high-performing multi-sensor metrology solutions all on one platform, they asked repeatedly for a similar solution for defect inspection. So, we developed on the same platform, with the same philosophy of modularity in hard- and software our defect inspection solutions.

Defect inspection module. Image Credit: FRT

By working on our existing mature platform, at the same time we are open to combining metrology and defect inspection components in the same tool. I guess this is the only solution on the market allowing such a broad combination.

What are the benefits of using this platform and how does it differ from others on the market?

The benefits are very clear: First of all, the paradox of customers demand a standard tool, sold hundreds of times, and a dedicated tool for their specific production situation is solved. Based on a stable platform with standard components and modules, every specific application can be adapted. Also, we provide options to add on more features, components, or algorithms, at customers' site at any time. So budget restrictions, new applications, or growing production capacities can be taken easily and economically smooth. These may be for example sensors, handling options, or software solutions. As already said, to my knowledge there is no comparison for this flexible but still fully standardized solution on the market.

How has FRT Metrology stayed at the forefront of the industry?

Like for everyone who is successful in our complex and demanding markets it is a permanent challenge of learning with the customer where the need is, developing the next solution, and building stable solutions and customer trust. With a fantastic team through all departments and by living the „art of metrology“ we permanently work on our goals to deliver the best solutions for metrology and inspection.

What’s next for FRT?

We just opened the door wide for our further global growth being a part of FormFactor Inc. for about a year now. This gives us the power and the global footprint to realize and further develop our steep growth rate and enables us to support our customers accordingly. On the applications and technology side, we are working permanently on our very own roadmap, trying to see where the needs on the customer's side are going.

About Dr. Thomas Fries

Thomas studied at the University of Saarbrücken in Germany, where he received a degree in physics in 1989. In then went on to do a PhD at Germany's University of Bonn in 1993. From 1993 to 1995, Thomas acted as the Head of Department for Surface Analysis at Günther Systemtechnik GmbH, Germany.Then in 1995, he went on to become Founder and CEO at FRT GmbH, Germany where he is still today.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.