Researchers at Wuhan and Lanzhou have fabricated an efficient Glass-Fiber Reinforced Plastic (GFRP) racetrack ring using Finite Element Analysis (FEM), practical calculations and extensive testing, resulting in low leakage and weight optimization of superconducting motors; thus, augmenting its operational efficiency and capabilities.

Image Credit: natatravel/Shutterstock.com

Background Information

The discovery of high-temperature superconductors in 1986 revolutionized the field of materials science and research.

It galvanized researchers to work tirelessly on improving the operational efficiency of electric motors by integrating superconductors that offered higher current density and almost zero electrical resistance to electric current flow. The hefty size of electric motors and low operational speeds were the core reasons for reduced efficiency.

The manufacturing of electric motors by using superconductors instead of ordinary elements proved to be fruitful and led to a notable increase in motor performance and efficiency, while considerably causing a reduction in constituent weight and motor volume. These features have made superconducting motors (SCM) the center of research globally.

High-Temperature Superconducting Motors

The research study by R. Schiferl and Stephen Umans has shown that the implementation of high temperature superconducting (HTS) materials has deducted the power loss by almost 50% along with a significant size decrement.

Until 1986, Liquid Helium was needed for the cooling of coils and the cost associated with this cooling process was exorbitant.

The discovery of HTS intrigued the rotary manufactures due to their characteristic critical temperature exceeding the boiling point of liquid nitrogen. Hence, the utilization of HTS materials for electric motors was called for.

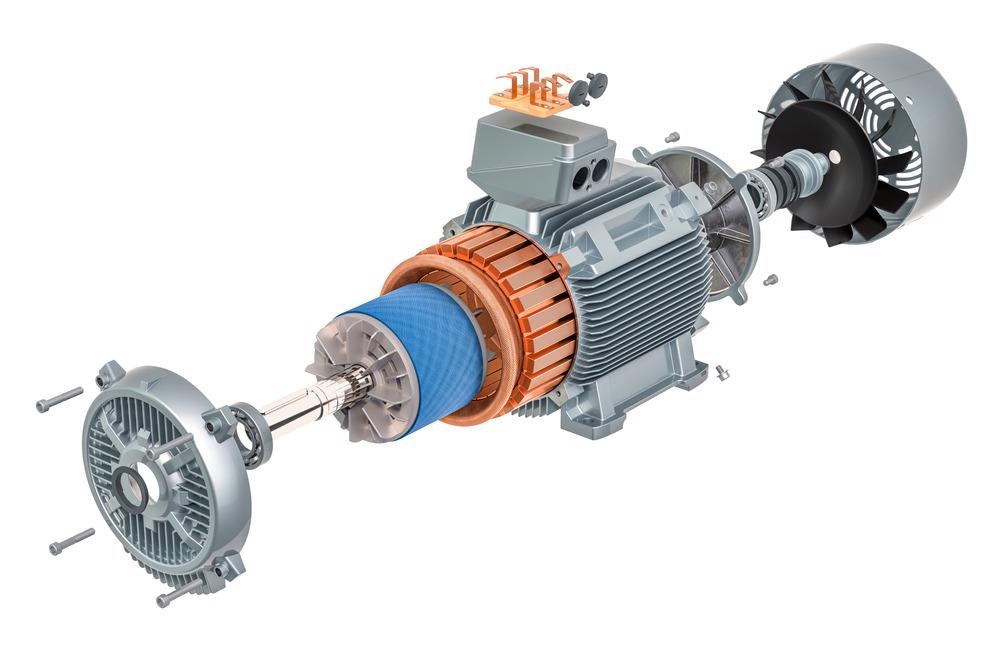

High-temperature superconducting motors (HTSM) contain a coil made of high-temperature superconducting material (HTS), unlike the conventional motors which utilize copper coils. A superconducting rotor is situated inside the conventional stator of HTS motors.

Specially designed inner and outer rotors constitute the main rotor of the motor. The inner rotor has HTS magnets and a cold mass, and it operates at a very low operational temperature. The outer rotor is composed of multi-layered shafts with a shielding layer for protection at high temperatures. A support and transfer system serves as the mechanical connection between the outer rotor shaft and the HTS magnet fixed on the cold mass.

White glass fiber composite raw material. Image Credit: TLaoPhotography/Shutterstock.com

The support and transfer system is a core component of HTSM and is made up of a torque tube axial support, a support tape and a support rod. The manufacturing of support tubes is done using GFRP due to its superior material attributes. These exceptional properties are the reason that the research team of Mr. Y. Zhou, F. Xie, H. Y. Jia and W. Chan selected GFRP for the fabrication of racetrack rings, the novel technology for HTSM.

Glass Fiber Reinforced Plastic Racetrack Rings

Commercial usage of GFRP began in the 1940s, owing mostly to demand from the marine sector.

Afterward, in 1960, due to lower material and production costs, GFRPs found their way in other industries and now they are being extensively used for various industrial applications. GFRP is a type of plastic composite that readily utilizes glass fibers to reinforce material properties.

GFRPs have excellent strength to weight ratio, stiffness, superior flexibility, significant fracture toughness, and resistance to corrosion and thermal resistance. “Pultrusion” is deemed as one the most effective methods for manufacturing GFRP, which consists of two essential steps.

The initial step termed “Impregnation” includes pushing the fiber resin and slit fabrics through a moist resin matrix reservoir for the generation of uneven part shape followed by the second step known as “cure”. In this step, the part shape is extruded through die fibrous materials, forming predefined structural fiberglass products or “Pultrusion” end products.

Racetrack Ring Research Study and Fabrication

In the latest study by Chinese researchers, the GFRP material racetrack ring was implemented in the novel flexible support system.

The racetrack ring is useful for the reinforcement of the cold mass attached to the outer rotor shaft. The leaf spring and support rod accommodated for the cold mass shrinking in the inner rotor while the specially designed racetrack ring was utilized to transfer the generated torque safely.

Specifically, pairs of racetrack rings were used to cater for the clockwise and anti-clockwise rotation of the motor. During the initial design and analysis process, the temperature effects were disregarded. The conceptual design and performance analysis was performed and Finite Element Analysis was used for validation of racetrack ring design.

Many support ring designs were under consideration initially but the thorough structural analysis including Von-Moises stress, Tensile force calculations and extensive lab testing revealed the D-shaped support ring design as the most suitable in terms of stress carrying capabilities.

The width and thickness of racetrack rings were fixed at 10 and 16 mm respectively while the D-shaped support rings were 3mm thick.

This reinforcement of the support system offered by the inclusion of a novel racetrack ring supported by D-shaped rings is useful in overcoming the issues of leakage faced in the past. Along with this, the smooth transfer of mechanical torque and forces to constituent rotary components decreases the wear and tear of moving parts, extending the lifetime of HTSM.

This novel innovation shall be useful in augmenting the efficiency of HTSM and enhancing their usage for various industrial purposes such as in ship motors in the marine industry as well as manufacturing of efficient generators, pumps, blowers and compressors for large scale industrial usage.

The aerospace sector also has shown keen interest in such efficient technology, and experimental research is being carried out on high-temperature superconducting ring magnets for electric aircraft applications. Thus, all industries are keen on utilizing this novel technology for efficient mechanical operations.

In short, superconducting motors have revolutionized the rotary machine industry and the structural support provided by the low weight GFRP racetrack rings has increased their efficacy up to 50%.

Keeping in view the interest of researchers and industrial professionals, it wouldn’t be wrong to assume that HTSMs could become one of the most utilized products in the future.

References

Balzli, M., Ashrafi, H., & Oskouei, A. V. (2016, August 15). Effect of harsh environments on mechanical properties of GFRP pultruded profiles. Composites Part B: Engineering, 99, 203-215. doi:https://doi.org/10.1016/j.compositesb.2016.06.019 https://www.infona.pl/resource/bwmeta1.element.elsevier-8ac27b05-4645-3e66-8810-a2f604cdbe91

Nam, G. D., Sung, H. J., Kim, C., Park, M., & Yu, I. K. (2020). Design and Characteristic Analysis of a 1 MW Superconducting Motor for Ship Propulsions. IEEE TRANSACTIONS ON APPLIED SUPERCONDUCTIVITY, 29(5), 1-5. doi:10.1109/TASC.2019.2902872. https://www.semanticscholar.org/paper/Design-and-Characteristic-Analysis-of-a-1-MW-Motor-Nam-Sung/e62bcda7619c5025077c55995052333d9478fc46

Schiferl, R., Flory, A., Livoti, W. C., & Umans, S. (2008, October). High-Temperature Superconducting Synchronous Motors: Economic Issues for Industrial Applications. IEEE Transactions on Industry Applications, 44(5), 1376-1384. doi:10.1109/TIA.2008.2002219 https://www.sciencedirect.com/science/article/pii/S2352484720303322

Zhou, Y., Xie, F., Jia, H. Y., & Chen, W. (2021, June 16th). Design, performance analysis, and testing of a GFRP racetrack ring for a high-temperature superconducting motor with a flexible support rotor. Journal of Mechanical Science and Technology, 10(35), 4427-4435. doi:https://doi.org/10.1007/s12206-021-0913-5 https://link.springer.com/article/10.1007/s12206-021-0913-5

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.