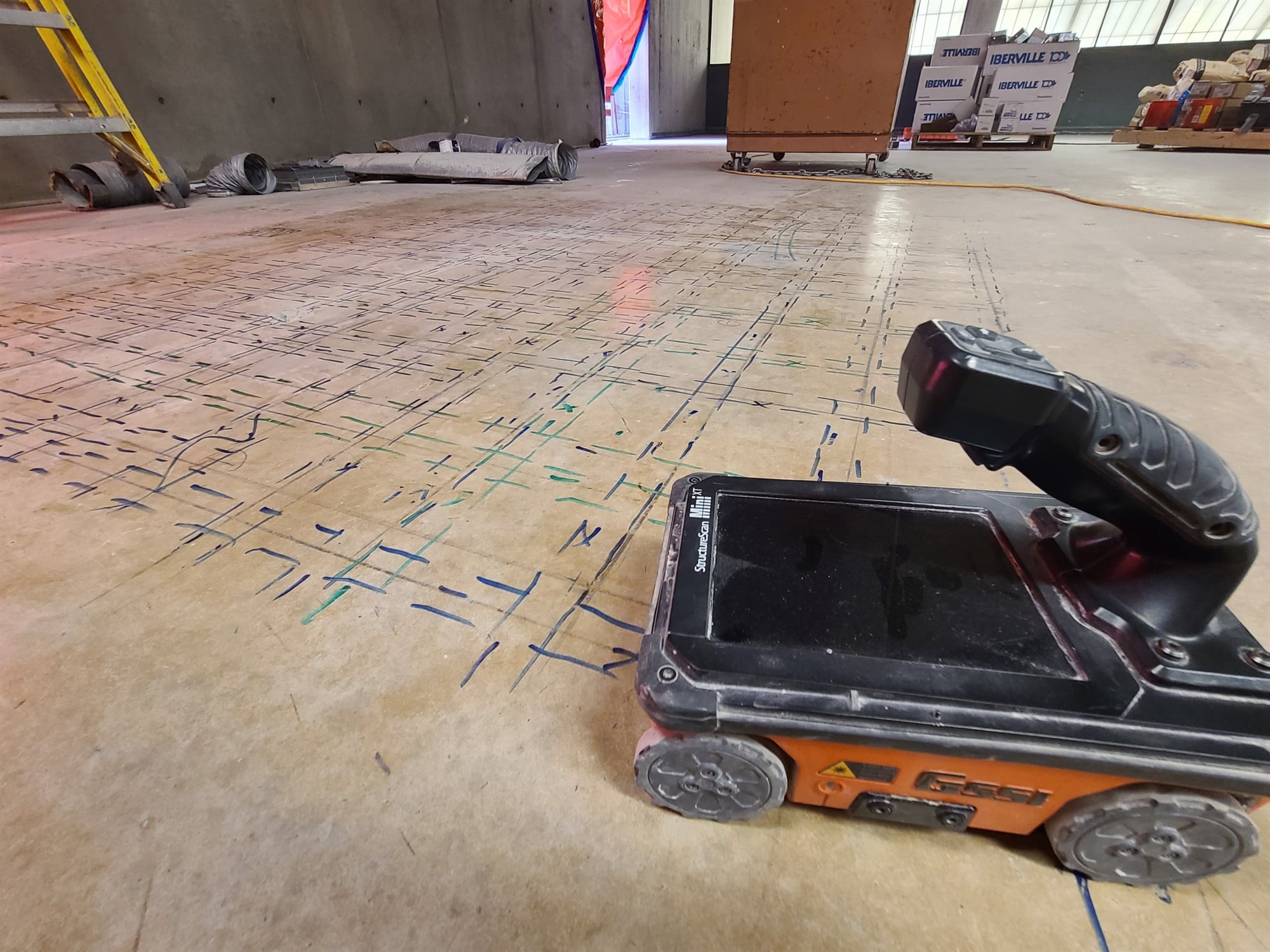

Ground penetrating radar (GPR) systems help contractors observe the interior features of concrete structures. This is extremely useful in drilling and cutting operations, as it prevents unwanted strikes and reduces delays, costs and risks.

Image credit: GSSI

The Risks of Drilling, Cutting and Coring Concrete

A major advantage of concrete is that it can be easily poured and formed into complex shapes, and reinforcing elements such as steel rebar and post-tension cables can be incorporated within it to enhance its ductility and tensile strength.1

This indicates that, while concrete structures may appear to be homogeneous from the outside, they are usually not. In fact, concrete structures are frequently internally complex, containing a variety of reinforcing elements, utility channels, anchors, voids and non-metallic objects.

As a result, cutting, drilling or coring concrete structures without first determining what is beneath them runs the risk of accidentally striking and damaging one of these internal features.

The severity of unintentional strikes varies. Repair costs for utility strikes, which are the most common, average around $1,000 per strike, not including downtime and delays while repairs are made.

Utility strikes can present a broad range of potential hazards, including gas explosion and electrocution,2 depending on the type of utility and the nature of the impact.

Accidental strikes of concrete reinforcing elements could prove even more dangerous: damaging post-tension cables or rebar jeopardizes the structural integrity of entire structures, posing major safety risks to site personnel and incurring significant costs.

Ground Penetrating Radar Fundamentals

Ground penetrating radar (GPR) allows contractors to avoid unintentional strikes by offering them a tool to pinpoint what is below the surface.

GPR is a technology that transmits and receives high frequency electromagnetic waves to picture the subsurface of materials. It was first used in the 1960s to study the interior of glaciers.

A transmitter sends an energy wave into the material of interest with GPR. When these pulses come into contact with a material boundary, they are partly reflected back to the surface.

The reflected pulse is picked up by a receiver at this point. The reflections from the object have a two-way travel time, resulting in a hyperbola shape, which confirms the presence of a structure or discontinuity inside the material.

Image credit: GSSI

Advantages and Applications of GPR in the Concrete Industry

GPR has proven to be a useful technique for the non-destructive analysis of concrete structures since the 1990s.3 GPR allows contractors to quickly trace electrical conduits, detect voids, recognize reinforcing elements and quantify slab thickness, on the site.4,5

GPR is useful for assessing the health of concrete structures in addition to avoiding accidental strikes. GPR has been used to identify defects such as concrete subsurface cracks, air gaps or moisture at interfaces and layered structure delamination.6,7

GPR can also be used to examine crucial bulk properties of concrete structures like moisture content and porosity.8

GPR has superior accuracy and versatility compared to other non-destructive methods like infrared thermography and radiography. GPR can detect a variety of features in reinforced concrete structures and does not necessitate any special safety precautions.

Furthermore, as GPR equipment is light and portable, it can be used to examine concrete structures in difficult-to-reach areas. The StructureScan Mini XT from GSSI, for instance, is only 4 lbs (1.8 kg).

By including a small GPR system in the toolbox, users can eliminate guesswork and drastically reduce the financial exposure, safety risks and delays that come with cutting and drilling concrete structures.

It is common to hire external scanning teams when a scan is badly needed, but having a small GPR system handy means that scans can be done as and when they are needed, with no additional expense or delays.

Owning GPR equipment can provide another source of income if the user wishes to contract out GPR scanning capabilities to others.

Image credit: GSSI

Ground Penetrating Radar Systems from GSSI

The StructureScan Mini GPR systems were created by GSSI to meet the needs of today’s concrete professionals. StructureScan Mini systems are small and rugged, and they can provide accurate, dependable and safe concrete imaging whenever and wherever it is needed.

The StructureScan Mini XT is a concrete analysis all-in-one GPR system with an embedded touchscreen display for data collection and interpretation by a single operator.

The Mini XT delivers high resolution at penetrations up to 24 inches, despite its diminutive size (60 cm). The Palm XT antenna can be attached to the Mini XT, allowing users to scan between small spaces and difficult-to-reach obstacles.

The StructureScan Pro is a rugged two-part system that includes the SIR 4000 control unit and two high-frequency concrete antenna options for added versatility. With antenna upgrades, the StructureScan Pro can broaden survey capabilities, including for bridge and utility applications.

References and Further Reading

- Tosti, F. & Ferrante, C. Using Ground Penetrating Radar Methods to Investigate Reinforced Concrete Structures. Surv Geophys 41, 485–530 (2020).

- Metje, N., Ahmad, B. & Crossland, S. M. Causes, impacts and costs of strikes on buried utility assets. Proceedings of the Institution of Civil Engineers - Municipal Engineer 168, 165–174 (2015).

- Near-Surface Geophysics. (Society of Exploration Geophysicists, 2005). doi:10.1190/1.9781560801719.

- Maierhofer, C. Nondestructive Evaluation of Concrete Infrastructure with Ground Penetrating Radar. Journal of Materials in Civil Engineering 15, 287–297 (2003).

- Case Study | Scanning Concrete Prior to Anchor Installations | GSSI. https://www.geophysical.com/wp-content/uploads/2021/02/GSSI-Case-Study-ScanningPriortoInstallingAnchors.pdf.

- Dinh, K. & Gucunski, N. Factors affecting the detectability of concrete delamination in GPR images. Construction and Building Materials 274, 121837 (2021).

- Colla, C. et al. Combination of NDT techniques for site investigation of non-ballasted railway tracks. PROCEEDINGS OF THE INTERNATIONAL CONFERENCE, RAILWAY ENGINEERING 2000, HELD LONDON, UK, JULY 2000 - CD-ROM (2000).

- Van Dam, R. et al. Assessment of Concrete Moisture and Porosity Using Ground-Penetrating Radar. in (2019).

This information has been sourced, reviewed and adapted from materials provided by Geophysical Survey Systems Inc.

For more information on this source, please visit Geophysical Survey Systems Inc.