The prevalence of semiconductors and embedded chip devices continues to increase, propelled by rising chip integration levels and processing capability, as well as declining costs and power consumption. Aging is a major issue for semiconductors that play a crucial part in applications requiring reliability or safety.

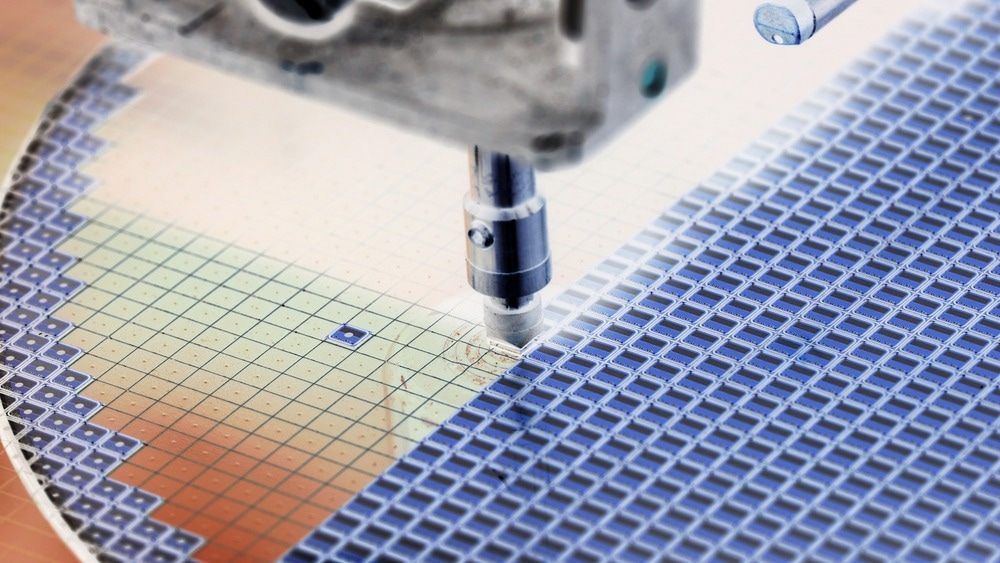

Image Credit: Macro photo/Shutterstock.com

What is Semiconductor Aging?

Semiconductor aging refers to the slow loss of electrical characteristics of the semiconductor device as a result of continuous use or prolonged exposure to various environmental conditions like temperature, moisture, irradiation, and electrical stress. Several processes, such as dopant dispersion, interfacial deterioration, and oxide breakdown, contribute to the aging process. These procedures result in modifications to the electrical properties of the device.

Effects of Semiconductor Aging

Significant impacts of semiconductor aging can contribute to malfunction. When a gadget ages, its electrical properties change, resulting in diminished performance and dependability.

One of the impacts of aging is a rise in the device's leakage current, which leads to a decrease in transmission quality and a rise in energy consumption. The decrease in threshold voltage caused by aging impacts the device's switching properties, such as turn-on and turn-off timings.

A device's trans-conductance declines with age, resulting in a drop in its bandwidth and gain. The deterioration of interfacial layers due to aging might result in changes to the capacitance and interface states of the device. In aging semiconductor devices, the breakdown of oxide is a crucial concern. Degradation of the oxide layer, which serves as an insulator, might result in device failure.

Significance of Semiconductor Age Testing

It is vital to test for semiconductor aging to ensure the device's durability and performance throughout its lifetime.

Semiconductor devices are utilized in several sectors where dependability is vital, including aircraft, medical equipment, and the military. Testing for the aging of semiconductors assures that the device will continue to operate reliably throughout its lifetime.

It reduces the expenses associated with equipment damage. Early diagnosis of deterioration enables preventative maintenance, which reduces repair and replacement expenses.

By detecting devices that are prone to fail and substituting them before failure, testing for semiconductor aging extends the product's lifespan. Additionally, testing helps in the identification of devices with deteriorated performance, allowing for their replacement or repair.

Traditional Semiconductor Aging and Testing

Many conventional procedures are used to evaluate the aging of semiconductors.

Time-Dependent Dielectric Breakdown (TDDB) is a common method for measuring the oxide breakdown of semiconductor devices. It entails delivering a battery voltage to the device's oxide layer and determining the period required for the oxide to degrade. Time to failure is an indication of the device's dependability.

Hot Carrier Injection (HCI) is a test for the aging of semiconductor devices caused by hot carrier injection. A high voltage is applied to the device to produce hot carriers, which are then injected into the device's channel area. The electrical properties of the gadget are then tested to identify the effects of aging.

Bias Temperature Instability (BTI) is a method used to test for the aging of semiconductor devices caused by bias temperature instability. The procedure entails supplying a bias voltage to the instrument and exposing it to varying temperatures. The electrical properties of the gadget are then tested to identify the effects of aging.

Electro-migration (EM) is a method used to test for the aging of semiconductor devices owing to the movement of metal atoms in the interconnects. It entails providing current stress to the device's metallic lines and determining the amount of time required for metal atoms to move, resulting in interconnect failure.

High-Efficiency Semiconductor Aging Testing with Data Processing

In the latest research published in the journal Microelectronics Reliability, researchers have presented a high-efficiency aging test technique that estimates the voltage stress based on the median deterioration of device electrical indicators rather than the substrate current, therefore reducing the test time while increasing its accuracy.

Pretest is the initial phase. The pretest is the initial phase. As a reference for later studies, some basic characteristics of the devices have to be assessed before the start of the pretest to guarantee that the devices are in excellent condition and free of manufacturing faults. Typical device characteristics are threshold voltage (Vth), trans-conductance (Gm), and drain current at saturation (Idsat). To make the procedure relevant to measuring various aging effects, the deterioration of electrical indicators between 4% and 6% were evaluated in the pre-test.

The HCI effect's drain voltage stress is roughly 1.3 times the operational voltage. At such voltage stress, the Idsat degeneration of several samples is examined. The deterioration ratio of Idsat is examined under various drain voltages. The voltage equivalent to a 5% decrease in Idsat is referred to as the drain voltage stress. The benchmark for the gate voltage stress is turning on the channel and seeing Idsat deterioration, which the standard operating gate voltage can do.

Image Credit: aslysun/Shutterstock.com

In the interest of obtaining model parameters, in addition to the voltage value established during the pre-test phase, two additional voltages within a range of 2 V around the estimated drain voltage stress are chosen. Using the same procedures, the link between device duration and deterioration is determined. Yet, as the channel length grows under the same test conditions, the deterioration is not readily apparent.

As the aging tests are conducted under over-biased settings to expedite the deterioration of the electronics, it is important to fit the collected data to the device aging model to get realistic parameters. Initially, the test data are first inspected, and data that considerably deviates are eliminated.

Typically, as the final test value, the mean of the data received from several samples is utilized. As the data produced from the aging test are discrete electrical index values, it is important to fit the processed data to develop the deterioration formula of semiconductor performance and determine the device's longevity. The validity of a model is directly impacted by the accuracy of curve fitting. It is vital to compare the accelerated test technique to the traditional test method to confirm its correctness under extreme conditions. Thus, the modeling of aging should be performed first.

Future Trends

Artificial intelligence is gaining popularity in the semiconductor business, and it is anticipated to play a large part in testing for aging. AI is capable of analyzing massive amounts of data and recognizing trends, making it simpler to forecast aging effects and execute preventative maintenance.

Another rising trend in the semiconductor sector is machine learning. It includes teaching computers to make predictions and learn from data. It is possible to apply machine learning to forecast the effects of aging on semiconductor devices and improve maintenance plans.

In the semiconductor industry, Non-Destructive Testing (NDT) procedures are becoming increasingly common. These approaches allow for the non-destructive testing of electronics, consequently decreasing costs and boosting productivity.

In-situ testing entails evaluating the gadget while it is in use. This technology gives real-time data on the performance and aging impacts of a device, allowing for preventative maintenance.

More from AZoM: The Current State of the Global Semiconductor Market

References and Further Reading

Moyer, B., 2022. What Causes Semiconductor Aging?. [Online]

Available at: https://semiengineering.com/what-causes-semiconductor-aging/

[Accessed 6 March 2023].

Yang, X. et. al. (2023). A high-efficiency aging test with new data processing method for semiconductor device. Microelectronics Reliability, 143, 114940. Available at: https://doi.org/10.1016/j.microrel.2023.114940

Lanzieri, L. et. al. (2023). A Review of Techniques for Ageing Detection and Monitoring on Embedded Systems. arXiv preprint arXiv:2301.06804. Available at: https://arxiv.org/abs/2301.0680

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.