How do you build materials tough enough for space - and smart enough to fix themselves? Inside the latest breakthroughs shaping the future of spacecraft durability, sustainability, and design.

The unique and extreme environment of outer space demands continuous research and technological development. Space materials must endure radiation, temperature extremes, mechanical stress, and high-velocity impacts.1

This article explores the emerging material trends in space science and recent advancements designed to improve performance in space.

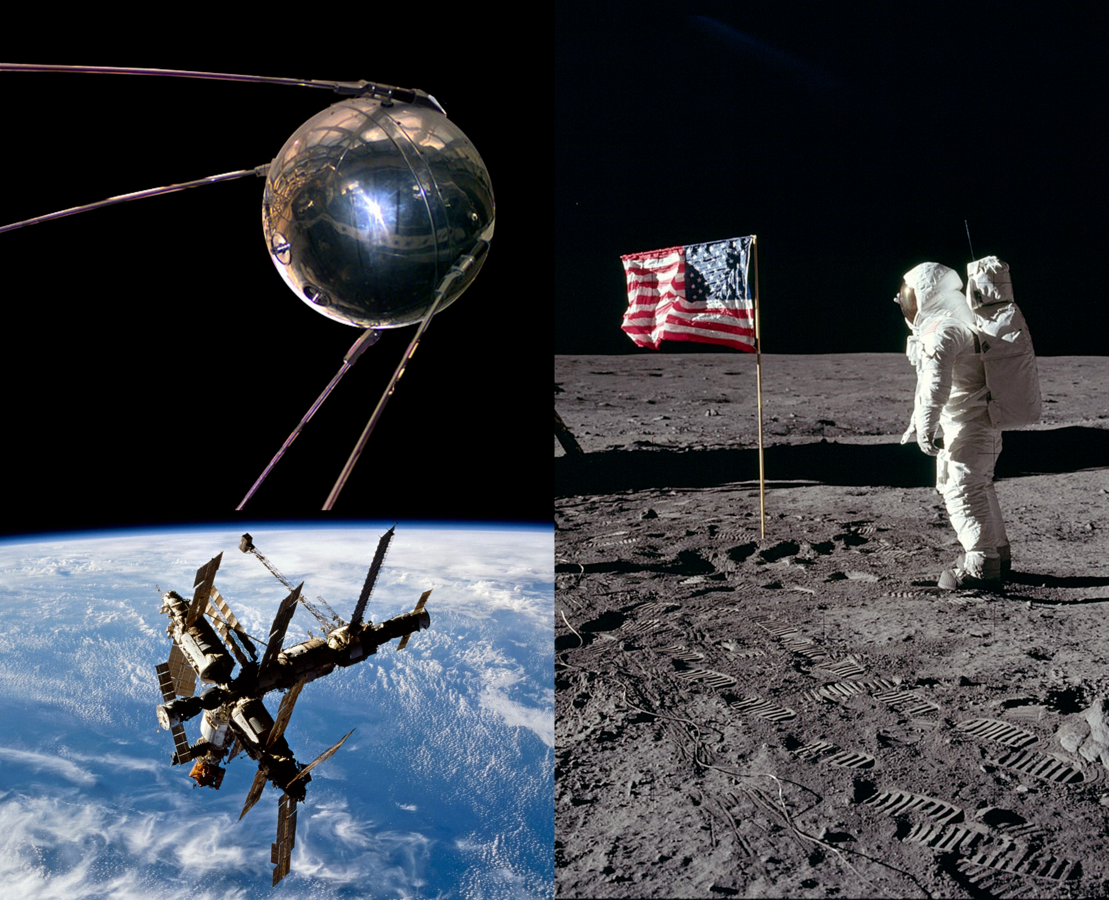

Where it Began

The roots of material science in space began in the mid-20th century during the dawn of the space race.

Image Credit: Indometeus/Wikimedia Commons

Image Credit: Indometeus/Wikimedia Commons

To begin with, rockets, space shuttles, and satellites predominantly used aluminium alloys for their favourable weight-to-strength ratios and ease of fabrication. The use of aluminium in aerospace rapidly expanded alongside the development of titanium alloys in the 1960s. Titanium's high strength, corrosion resistance, and lighter weight compared to steel made it essential for structures exposed to intense stresses and temperatures.2,3

Over the decades, materials science has evolved from focusing solely on mechanical properties to addressing radiation resistance, thermal fatigue, and environmental degradation, essential criteria for prolonged space missions. Integrated ceramics, advanced polymers, and coatings engineered for atomic oxygen erosion and ultraviolet radiation protection have become standard.

Now, in 2025, what materials are sending astronauts to space?

Sustainability in Space

Economic and environmental imperatives are two essential aspects of today’s material science research.

The development of reusable launch systems, even demonstrated by companies like SpaceX, has highlighted the importance of materials that can withstand multiple launch and re-entry cycles without significant degradation, instead of single use equipment.4

To meet these repair and reuse targets, material durability is critical. Optimizing materials to ensure longevity in reusable rockets and spacecraft is guiding research into wear-resistant coatings, radiation-resistant materials, and self-healing composites to make them cost-efficient and reduce space debris.

Watch Live: SpaceX Falcon 9 rocket launches from California with Starlink satellites

Video Credit: Spaceflight Now/YouTube.com

Composites that Resist the Extremities of Space

Carbon Fiber Reinforced Composites

These high-performance composites were first introduced in the 1970s and 1980s. Carbon fiber reinforcement is a well-known addition that improves the strength-to-weight ratio of composites.

Recent efforts have enhanced these composites through nanoscale engineering for greater toughness and thermal stability, directly contributing to reduced payload mass and extending spacecraft longevity.

In late 2024, the University of Bristol launched a new generation of carbon fiber reinforced composites to the International Space Station for long-term exposure testing.

These materials were designed to tolerate temperatures from -150 ºC to +120 ºC, space debris impacts, strong electromagnetic radiation, and atomic oxygen erosion. Some composites incorporated nanoparticles to enhance properties, focusing also on shielding against galactic cosmic radiation and material sustainability through recyclability.5

Hybrid Composites

Combining reinforcement phases in hybrid materials, such as with nanoparticles, glass, and natural jute fibers, can improve both mechanical and thermal properties for aerospace applications. Hybridization can enhance stiffness, strength, and temperature resistance through the complementary interaction of nano- and micro-scale reinforcements. 6

Nanoscale materials such as carbon nanotubes and graphene are explored for lightweight structures, conductive coatings, and embedded sensors. The integration of smart materials, such as shape memory alloys and piezoelectric materials that harvest mechanical energy, may enable the design of reliable and efficient systems that autonomously respond to environmental changes in space operations.

Self-Healing Polymers and Composites

Self-healing polymers and composites autonomously repair damage such as scratches or cracks caused by a sudden impact. These materials embed micro or nano-capsules or functional fillers that activate repair mechanisms when cracks form, preserving structural integrity without external intervention.

Get all the details: Grab your PDF here!

With this ability to self-heal comes durability in spacecraft, prolonging their lifespan and reducing maintenance needs. It's a practical and hands-free approach to enhancing material structure and mission safety.7,8

Radiation Resistant

Recent research by Abd El-Hameed (2022) highlighted the ongoing efforts to improve the composite material resilience in spacecraft and satellite systems against radiation, including protons, electrons, neutrons, and gamma rays.

The study found that radiation can cause gradual changes in mechanical, thermal, and optical properties, affecting material stability over time. Current research trends focus on developing radiation-tolerant composites, applying protective coatings, and designing layered shielding systems to maintain material reliability in orbit.1

Microgravity Testing

A study led by Nagoya City University and ANSTO last year investigated the self-assembly of colloidal clusters without gravity-induced disturbances at ISS. These clusters, suspended nano- and micrometer-scale particles, exhibited unique light scattering properties relevant to photonics and advanced optical communications.

Using UV curing to preserve the clusters’ delicate architectures for neutron scattering analysis on Earth will help in developing novel optical materials and devices for space and terrestrial technologies.9

In yet another interesting research under microgravity, cement solidification was investigated. It used artificial intelligence to analyze cement hydration and hardening, providing insights for constructing durable structures in space. This research could drive in-situ manufacturing of building materials beyond Earth.10

The Future Prospects

Continuous research and improvements are being made to explore extended space for mankind's benefit. One promising material processing technique is plasma-enabled additive manufacturing, which is suited for in-space fabrication and repair and may result in more sustainable and reliable space structures for extended missions.

The microgravity and vacuum conditions in space provide a controlled environment that may allow for the precise construction of complex structures with less thermal and mechanical stress than Earth-based processes.11

Image Credit: FAMILY STOCK/Shutterstock.com

Image Credit: FAMILY STOCK/Shutterstock.com

Conclusion

Materials science continues to contribute to addressing the specific challenges posed by the space environment. Progress from early aerospace materials to contemporary composites and nanoscale materials reflects ongoing efforts to improve strength, durability, and functionality under harsh conditions.

Current research emphasizes sustainability and reusability, including developments in self-healing polymers, radiation-resistant coatings, and hybrid composites aimed at extending spacecraft operational life.

Emerging technologies, such as plasma-enabled additive manufacturing and microgravity-based materials research, may provide practical methods for in-space fabrication and maintenance, which could support longer-duration missions.

How are sensors accelerating space tech? Click here for more.

References

- Abd El-Hameed, A. M. (2022). Radiation effects on composite materials used in space systems: a review. NRIAG Journal of Astronomy and Geophysics, 11(1), 313-324. https://doi.org/10.1080/20909977.2022.2079902.

- El-Hameed, Afaf & Abdel-Aziz, Y.. (2021). Aluminium Alloys in Space Applications: A Short Report. Journal of Advanced Research in Applied Sciences and Engineering Technology. 22. 1-7. DOI: 10.37934/araset.22.1.17.

- Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium Alloys for Aerospace Applications. Advanced Engineering Materials, 5(6), 419-427. https://doi.org/10.1002/adem.200310095.

- Cylinders, A. C. (2025). Space Exploration in 2025: Trends and Predictions https://ams-composites.com/space-exploration-in-2025-trends-and-predictions/.

- Montoya, J. (2024). High-Performance Materials from Earth to Space https://www.plasticsengineering.org/2024/11/high-performance-materials-from-earth-to-space-007274/.

- Abdullah, M., Abedin, M. Z., & Bakaul, S. R. (2025). A review on synthesis and characterization of composites reinforced with nanoparticles, glass fiber, and jute fiber for aerospace applications. Results in Surfaces and Interfaces, 19, 100492. https://doi.org/10.1016/j.rsurfi.2025.100492.

- Ince, J. C., Peerzada, M., Mathews, L. D., Pai, A. R., Al-qatatsheh, A., Abbasi, S., Yin, Y., Hameed, N., Duffy, A. R., Lau, A. K., & Salim, N. V. (2023). Overview of emerging hybrid and composite materials for space applications. Advanced Composites and Hybrid Materials, 6(4), 130. https://doi.org/10.1007/s42114-023-00678-5.

- Gao, L., Yang, Y., Xie, J., Zhang, S., Hu, J., Zeng, R., He, J., Li, Q., & Wang, Q. (2020). Autonomous Self-Healing of Electrical Degradation in Dielectric Polymers Using <em>In Situ</em> Electroluminescence. Matter, 2(2), 451-463. https://doi.org/10.1016/j.matt.2019.11.012.

- Staff, A. (2024). Avanced materials reseach in microgravity earns NASA recognition https://www.ansto.gov.au/news/advanced-materials-research-microgravity-earns-nasa-recognition.

- Doran, D. (2024). Science in Orbit : Results published on Space Station Research in 2024 https://www.nasa.gov/missions/station/iss-research/science-in-orbit-results-published-on-space-station-research-in-2024/.

- Levchenko, I., Keidar, M., Baranov, O., & Alexander, K. (2025). Plasma-enabled additive manufacturing in space: Perspectives, innovative material processing technologies, and emerging challenges. Progress in Aerospace Sciences, 157, 101125. https://doi.org/10.1016/j.paerosci.2025.101125.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.