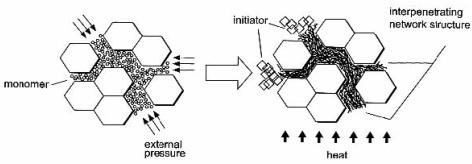

Bone Cement Composites During the last 5 years bone cement materials have grown in popularity and are very promising osteoconductive substitutes for bone graft. They are prepared like acrylic cements and contain a range of powders such as monocalcium phosphate, tricalcium phosphate and calcium carbonate, which is mixed in a solution of sodium phosphate. These cements are produced without polymerisation and the reaction is nearly non-exothermic. The final compounds are reported to have a strength of 10-100 MPa in compression while 1-10 MPa in tension, although very weak under shear forces. These composites are currently used in orthopaedics in the management of fractures. It has been suggested that these materials could improve the compressive strength of the vertebral bodies in osteoporosis. Injection of calcium phosphate cement has been shown to be feasible and it does improve their compressive strength. Hydroxyapatite Composite Materials Preparation of hydroxyapatite/ceramic composites through the addition of various ceramic reinforcements has been attempted, metal fibres, Si3N4 or hydroxyapatite whiskers, Al2O3 platelets and ZrO2 particles. In many cases, the composites could not be successfully prepared and, because of problems related to a poor densification the mechanical properties could not be improved. Hydroxyapatite/metal and hydroxyapatite/polymer composites are two typical classes of materials, which have been examined for improving the toughness characteristics of synthetic hydroxyapatite. In both cases, a toughness improvement can be found, due to a crack-face bridging mechanism operated upon plastic stretching of metallic or polymeric ligaments. Zhang et al. proposed a toughened composite consisting of calcium hydroxyapatite dispersed with silver particles. This material was obtained by a conventional sintering method. It was reported that the toughness of these composites increased up to 2.45 MPa m1/2 upon loading the mixture, with (30 vol%) silver. The use of silver is not only for taking advantage of the ductility of silver in terms of fracture toughness, but also because silver is inert and has anti-bacterial properties. Attempts to supersede metal alloys by carbon-fibre reinforced plastics and by various composites to stabilize fractures have met with limited success. Although a new titanium metal core composite hip implant has been clinically assessed in Europe with promising results. Biomimetic Hybrid Composites The conventional way to synthesize an inorganic material-based composite is to subject a mixture of the constituent phases to heat treatment. This process is also common in the biomaterials production arena; however, it is conceptually far from the biomineralization process, which occurs in nature. The natural process produces fine hybrid structures, which are hardly reproducible by classic consolidation processes. Traditional sintering route is not directly applicable to produce ceramic/polymer composites because no polymer will stand at the densification temperature of any ceramic material. Hydroxyapatite/polyethylene composites have been obtained by loading the polymeric matrix with the inorganic filler. In recent years, several research groups have demonstrated the feasibility of in vitro techniques for the synthesis of biomimetic material structures. The sophistication of the biomimetic route has not been paired yet and these techniques, so far, have not proved to be fully applicable for clinical applications although various companies started to produce a range of clinical products. It can be easily predicted that more and more dense hybrid materials will be introduced, opening a completely new perspective in biomaterials production and application methods. A new alternative route, -based on an in situ polymerization process, carried out into an inorganic scaffold (with submicrometer-sized open porosity)-, has also been recently proposed. This method is an intermediate one between conventional sintering and biomineralization in vitro, because it still employs sintering for the preparation of the inorganic scaffold, but the subsequent hybridisation of the scaffold with organic phases is carried out through a chemical route. This method enables the synthesis of biomimetic (hybrid) inorganic/organic composites, while aiming at relatively complex structural designs; it is rather simple and easily reproducible process. A schematic of this efficient synthesis route is given in Figure 1. |

| | Figure 1. Schematic representation of the in situ polymerisation synthesis route of new generation hybrid materials. | A common characteristic of natural biomaterials such as bone, nacre, sea urchin tooth and other tough hybrid materials in nature is the strong microscopic interaction between the inorganic and the organic phases. This characteristic allows the organic phase to act as a plastic energy-dissipating network, forming stretching (bridging) ligaments across the faces of a propagating crack in a nanoscale level. Such complexity has led to the common perception that, to mimic natural designs, in situ synthesis techniques should be adopted. Precipitation of calcium carbonate or hydroxyapatite into a polymeric matrix, for example, has been proposed as a novel synthetic route to biomimetic composites. Despite significant advances in understanding biological mineralization and developing new fabrication processes, the composites to date obtained by these methods are by far in embryonic stage for actual applications, due to their low structural performance. The results of fracture tests carried out on two natural biomaterials, bovine femur and Japanese nacre (Crassostrea Nippona), in comparison with a synthetic hydroxyapatite/nylon-6 composite obtained by in situ polymerisation of ε-caprolactam infiltrated into a porous apatite scaffold showed that the high work of fracture achieved is about two orders of magnitude higher than that of monolithic hydroxyapatite, and it is due to stretching of protein or polymeric ligaments across the crack faces during fracture propagation. Summary Although the nanoscale modelling of synthetically manufactured hybrids and composites is still in infancy, mimicking natural microstructures while using strong synthetic molecules may lead to a new generation biomaterials, whose toughness characteristics will be comparable with the materials available in the nature. A formidable challenge remains on the optimisation of their morphology and bioactivity in these novel hybrid composites. |