| Lightweight vehicles are big news in the automotive industry at the moment, following the launch of the ultralight steel. Lighter vehicles offer the benefits of materials and energy savings, and so are more environmentally friendly. But weight cannot be trimmed from a car without design changes, which is why new ways of producing lightweight steel components - and of reducing the total number of components - are vital for the future. One such technique, already proven in the ULSAB project, is hydroforming. What is Hydroforming? Hydroforming uses fluid pressure in place of the punch in a conventional tool set to form the part into the desired shape of the die (figure 1). The technique is very useful for producing whole components that would otherwise be made from multiple stampings joined together. For example, a typical chassis component that would normally be made by pressing up to six channel sections and joining by spot welding can be hydroformed as a single part. Considerable mass savings are possible through eliminating the flanges required for welding and using thinner steel. Yet stiffness is maintained owing to the elimination of the discontinuous spot-welded joints. |

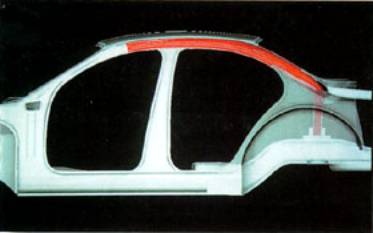

| | Figure 1. The high pressure hydroforming machine in use at British Steel. | Acceptance of Hydroforming Hydroforming is already widely used - in the US, more than a million engine cradles a year are produced by hydroforming processes, and in Europe the technology is being used in sub-frames for models such as Ford’s Mondeo and General Motors’s Vectra. Some 2.8 million components a year for one of Chrysler’s model are produced by hydroforming, too. However, as hydroforming - particularly high-pressure hydroforming - is at the frontier of modern steel technology, many designers and engineers still need convincing of its capabilities. Types of Hydroforming There are four main types of hydroforming: • Hydroforming of tubes, usually at low pressure, is the most widely used technology at present, with hydroformed tubular parts offering improved integrity and structural performance. • Low pressure hydroforming simply re-shapes tubes, producing a very good shape, but is not as useful if better cross-section definition is required. • High-pressure hydroforming, totally changes the tube shape and alters the length to circumference ratio by up to 50%. It gives very good tolerance control, being a highly robust process. • Panel hydroforming at high pressures is used in the aerospace industry, and is expected to be used for applications in the automotive industry in which hydroforming is needed to get the right material flow. Hydromechanical Forming Meanwhile, hydromechanical forming has a rapidly developing future in the manufacture of tight panels, such as roof panels. The process produces essentially flat panels with a controlled degree of deformation and tightness. Hydraulic pressure is used to expand the material into the die set with uniform strain. The punch then comes down to re-deform the metal into the required flat panel. Pillow Hydroforming ‘Pillow’ hydroforming uses hydraulic pressure to form a component from two steel sheets that have been welded around their perimeter. This allows the hydroforming of pillars that need to be slim at the top and wider at the bottom, for example. It also makes it easy to leave a weld flange for subsequent assembly. Obstacles to Widespread use of Hydroforming One of the biggest obstacles to the more widespread use of hydroforming lies in persuading people of its benefits. Designers and engineers used to working with press-tools find it difficult to grasp the principles of hydroforming (although those with knowledge of plastic moulding can more readily accept it). If hydroforming is to be used in more than just a few specific components, there must be a whole new approach to the design and architecture of a vehicle. As one leading industry figure says, “if companies design for hydroforming, then it will be more widely used. But that is the whole point - design concepts have to be changed when considering this technology”. This view is echoed by an industry research specialist, “it has to be very carefully designed for. Most of the applications of high-pressure hydroforming I see are very poor - they are not recognising its full potential”. However, change is coming - particularly in Germany where hydromechanical forming is well advanced. The twin demands for lower weight and high strength are likely to drive the switch to hydroforming at an increasing rate. In the UK and continental Europe, high volume manufacturing is geared towards making panels with traditional presswork processes. The amount of capital tied up in presswork technology is inhibiting automotive companies from adopting hydroforming for production of the ‘body-in-white’. Another factor is that, taken in isolation, hydroforming is relatively expensive. Benefits of Hydroforming However, the ULSAB study - in which British Steel is a participant - shows the way forward with its side roof rails being produced by hydroforming, figure 2. The rails are single hydroformed components that replace up to eight press-formed components (each of which requires a tool and die set) and eliminate costly sub-assembly. The rails are lightweight and structurally much more efficient than the conventionally constructed parts. In this example, productivity and cost benefits mean hydroforming is clearly favoured. It also shows that hydroforming gives the greatest benefits when it is used to integrate components or functions as part of a holistic design process. |

| | Figure 2. Hydroformed side roof rail indicates in red. | Hydroforming is more than just another way of creating a component. Hydroforming alters the functionality of components and assemblies, and this may have consequences on the design of the rest of the structure. The potential benefits of applying hydroforming should be considered early in the design process. Achieving the Benefits of Hydroforming To achieve the benefits cost-effectively, designers need to work in partnership with experts who have specialist knowledge of hydroforming, including hydroforming machine manufacturers and - very importantly - materials suppliers who are able to provide expertise on tube manufacture with an emphasis on high strength ductile steels. New tube making techniques are needed so that high strength steels can be used to make the higher diameter/thickness ratios required for lightweight applications. The current tube manufacturing techniques can only produce tubes with a diameter/thickness ratio of 60:1. Areas that can Benefit from Hydroforming Techniques Another area ripe for exploitation is lightweight applications for hydromechanically formed panels and other components made using ‘pillow’ forming techniques. Any structural component composed of inner and outer panels can be re-engineered as a ‘pillow’ hydroformed structure, ranging from a door to a complete body side. The technology can also be used for making shaped containers to fit neatly into available spaces, such as fuel tanks, washer reservoirs and overflow containers. There is great potential for these panels and for hydromechanical forming in the creation of key components such as floor pans, van body sides and body roof panels. The hydroforming of such components will provide weight savings in combination with improved performance. Summary In general, hydroforming is a technically elegant process. It is also a much more robust and practical process than many in industry will admit, and this robustness alone will ensure its increasing use. But, aside from the cost, one sticking point remains. Hydroformed components require different assembly techniques because single-sided welding is necessary. So engineers developing a total supply chain, incorporating the welding robots, must also adapt to allow the introduction of hydroforming. Continuous fusion welding, which is a slow process with a large heat-affected zone, or automatic laser welding are both suitable joining techniques for hydroformed components. Laser welding is already used in non-critical parts of a car body structure, such as joining the roof panel to the roof rail. The technology has a high initial cost, but benefits include on-line inspection using the laser beam. Work on the laser welding of hydroformed components is being carried out at British Steel's Welsh Technology Centre, where the UK’s first high-pressure hydroforming machine was commissioned earlier this year. The benefits hydroforming can bring to the industry are, without doubt, tremendous. But to profit from them, designers and engineers throughout the production process must be prepared to change both their ways of working and their thinking. |