The DIL 502 Expedis® Supreme represents the latest in dilatometer technology, built for both advanced research and high-end industrial applications. This fully equipped system offers exceptional versatility, with a single device covering an extraordinary temperature range of –180 °C to 2800 °C.

Alongside the graphite furnace for ultra-high temperatures (up to 2400 °C/2800 °C), the system supports multiple interchangeable furnaces, covering a wide range of temperature spans and atmospheric conditions.

- Achieve consistent and reliable results every time: Automatic Specimen Length Detection eliminates manual measurement errors by automatically detecting the specimen’s initial length before testing.

- Adjustable thermocouple positioning: An adjustable thermocouple guided by a flexible rod easily accommodates specimens of various lengths. This allows for precise placement without bending or damaging the specimen.

- AutoVac enables Inert Atmosphere Testing: The optional AutoVac system facilitates rapid evacuation and gas refill for measurements under pure inert atmospheres, which is ideal for studying oxidation-sensitive materials.

- MultiTouch Technology Provides Stable Sample Positioning: Achieve stabilized, repeatable specimen placement with MultiTouch's unique, tail-like motion, which optimizes positioning and enhances measurement reliability.

The Method for Determination of Dimensional Changes

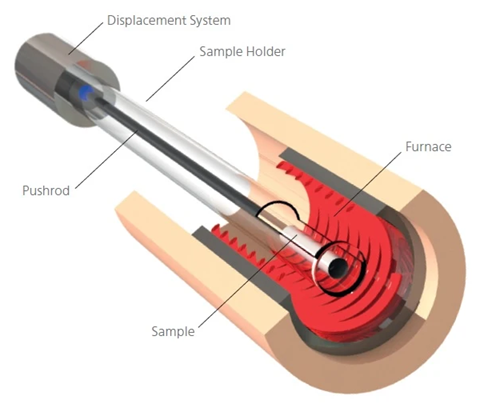

Pushrod dilatometry measures how a material’s dimensions change as it is heated or cooled over time. In this method, the sample is placed in a furnace with a precisely controlled temperature program. As the temperature shifts, the material expands or contracts, and a pushrod in contact with the sample moves to follow these changes. The pushrod’s movement is measured with high precision, revealing the exact change in the sample’s length.

This technique can be used to study:

- Thermal expansion or shrinkage

- Sintering of ceramics or metals

- Glass transition and softening point of polymers

- Phase transitions

By understanding how materials behave across temperature ranges, scientists and engineers can design products that perform reliably under real-world conditions.

View inside the DIL 502 Expedis® furnace. Image Credit: NETZSCH-Gerätebau GmbH

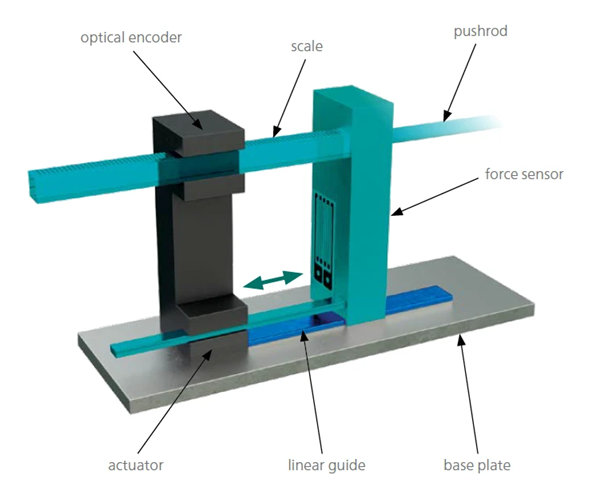

The Unmatched Precision of the NanoEye Displacement System

With conventional dilatometry, gaining higher resolution often means giving up measurement range - and vice versa. The NanoEye system removes that compromise.

The NanoEye system offers ultra-high resolution along with an exceptionally wide measurement range, establishing a new benchmark for precision in thermal expansion analysis.

At the core of the DIL 502 Expedis® is the advanced optoelectrical NanoEye displacement system. This state-of-the-art technology delivers exceptional linearity in every measurement, surpassing the capabilities of traditional dilatometry systems. A high-precision linear encoder converts position into a digital signal with unwavering accuracy, unaffected by temperature changes or sample length.

Image Credit: NETZSCH-Gerätebau GmbH

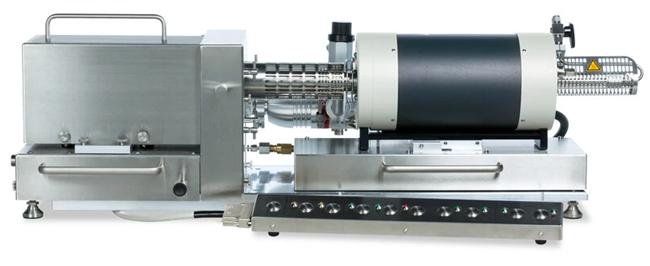

DIL Expedis® Supreme Glovebox Version

For Investigations with Special Care

The glovebox version of the NETZSCH DIL 502 Expedis® Supreme enables precise analysis of oxygen- or moisture-sensitive materials within a fully protected atmosphere. It’s also ideal for characterizing samples that require the user to be shielded from their properties.

Its stainless steel housing eliminates the risk of plastic components interacting with either the sample or the surrounding environment.

For applications requiring measurements up to 1650 °C (furnace temperature) in an argon atmosphere, a specially engineered rhodium furnace is available to ensure optimal performance.

DIL Expedis® glovebox version. Image Credit: NETZSCH-Gerätebau GmbH

Maximize Lab Efficiency with the Energy-Smart DIL 502 Expedis®

Around the world, there’s a growing urgency to save energy and use it more efficiently. From industry labs to university research centers, people are working hard to find smarter ways to conserve resources and tap into alternatives.

The DIL 502 Expedis® was built with that same mindset and is at the forefront of optimizing energy use. Instead of relying on bulky, power-hungry water-cycle thermostats, it uses advanced electronic temperature control to keep conditions perfectly stable. That means you get highly accurate thermal expansion measurements while using less energy and creating less heat waste in your lab.

It also includes customizable Idle and Eco modes that automatically dial back power when the instrument isn’t in use. The payoff comes in the form of lower CO2 emissions, a greener workspace, and no trade-off in performance or ease of use.

Specifications

Source: NETZSCH-Gerätebau GmbH

| |

| Temperature range |

-180 °C to 2800 °C |

| Furnaces |

- Fused Silica

- Silicon Carbide (fast cooling)

- Copper

- Stainless Steel

- Rhodium

- Graphite (2000 °C/2400 °C/2800 °C)

|

Specimen

dimensions |

Length: Max. 52 mm

- (Graphite furnace: 25 mm)

- Ø 12 mm standard (optional Ø 19 mm max.)

- Ø 8 mm in dual specimen holder system

|

| Heating rate |

- 0.001 … 50 K/min

- Graphite: 0.001 … 100 K/min

|

| Gas flow control |

1-way MFC or optional 3-way/4-way MFC |

| Measuring range |

± 25000 μm |

Force range

(load at the sample) |

10 mN … 3 N

(compressive and tensile force depending on sample holder) |

| ΔL Resolution |

0.1 nm |

| Force resolution |

0.001 K |