Aug 13 2009

3B, a leading manufacturer of fibreglass products for the reinforcement of thermoplastics and thermosets, is going to exhibit for the first time at the China Composites Expo, Shanghai, September, 2nd - 4th. This latest move reflects the company's strategic expansion beyond its core European market-base and in particular focusing on China as an important growth market for many of its key application areas.

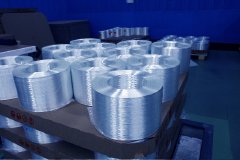

3B Advantex™ Direct Roving.

3B Advantex™ Direct Roving.

At its stand B4419, 3B will be supported by Shanghai-based GoodStra Chemical Co. Ltd, its agent and representative in China. Goodstra Chemical is a specialised provider of sales, marketing and technical support in the glass fibre business with over 13 years experience in fibreglass and composite applications in the wind energy, electricity, automotive, high pressure cylinders & pipes markets.

3B's highlights at the show will centre on its Direct Rovings and CFM (Continuous Filament Mat) product lines from its Advantex and HiPer-tex ranges and include:

- Advantex Direct Rovings SE 1500 used as an input for weaving and knitting operations for higher stiffness and enhanced fatigue performance in epoxy laminates

- Advantex Direct Roving SE 8400 LS (Low Seeds) specifically developed for composite high voltage electrical insulators rods and designed for pultrusion processes.

- Advantex CFM M8615 used as an infusion media for close mould applications in wind energy turbine blade applications.

- Advantex CFM M8643 for pultrusion processes for wide, long and heavy parts as well as narrow and complex profiles.

- Advantex Rovings for high pressure cylinder applications such as CNG (Compressed Natural Gas) cylinders. Showing much higher corrosion resistance than traditional E-Glass, Advantex Rovings are now approved to be used for high pressure vessels that meet ECE110, ISO 11439 & NGV-2 standards.

- HiPer-tex B15 Rovings designed for hard composite armour applications such as composite blast panels, ballistic panels, and spall liners for military and law enforcement vehicles, security vehicles and naval vessels that combine optimal protection with light weight and affordable cost.

Compared to E-glass, HiPer-tex glass fibre delivers overall superior performance: 30 percent higher strength; 17 percent higher stiffness; 45 percent higher strain energy; 10 times greater fatigue resistance and 30 percent lower coefficient of linear thermal expansion. HiPer-tex glass fibre delivers these benefits in ballistic applications that meet the following standards: FB4, STANAG 4569 Level 2 and STANAG 4569 Level 4.