Feb 4 2016

Researchers at the National Institute of Standards and Technology (NIST) have combined advanced nanometer-scale gratings and a Space Age-era thin-film polymer, to invent a novel technology. This technology can be used to fabricate routers and switches for optical signals, energy-efficient full-color video displays, and smart windows and coatings.

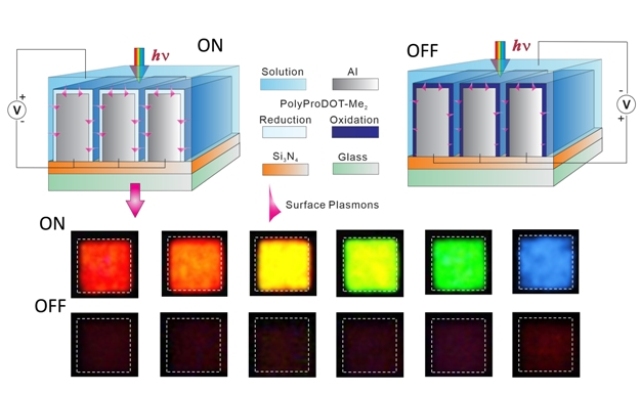

In this schematic, light enters from above and encounters a nanometer-scale grating made of aluminum coated with a special “electrochromic” material. Light passes through the nanograting as surface plasmons, oscillations that travel at the interface of a metal and a dielectric (insulating) material. The spacing of the slits serves to filter out all but one color of light, and an additional layer of silicon nitride further spectrally purifies the escaping light. (Credit: T. Xu and A. Agrawal/NIST)

In this schematic, light enters from above and encounters a nanometer-scale grating made of aluminum coated with a special “electrochromic” material. Light passes through the nanograting as surface plasmons, oscillations that travel at the interface of a metal and a dielectric (insulating) material. The spacing of the slits serves to filter out all but one color of light, and an additional layer of silicon nitride further spectrally purifies the escaping light. (Credit: T. Xu and A. Agrawal/NIST)

Electrochromic polymers are a special class of materials, which can change from clear to colored, and reverse the process again when the electrical charge of the polymers undergoes a change. Their widespread application has been stalled because the color transformation is based on how rapidly electrons can go into and come out of the material. This can take several seconds based on the film thickness. A good idea could be to make the films thinner in order to increase the speed of the color change, but reducing thickness of the film can alter the color contrast, and display a semitransparent black tint when an opaque black is desired.

An electrochromic display employing an additive color scheme - where green, red and blue are blended to realize full color - would mean having six transparent electrically conducting layers, resulting in a substantial increase in the manufacturing cost.

By employing clever engineering, the researchers at NIST solved this impasse by applying a thin electrochromic polymer layer over an aluminum nanograting. In this setup, the light initially encounters the nanograting which, as per the slit spacing, filters out all except one color of light. The electrochromic coating modulates that light by permitting all or some or none of it to pass through. A display according to this scheme will have many nanogratings, which can act as single-color pixels whose colors, by addition or subtraction, create all of the rainbow’s colors, with each pixel having adjustable contrast or brightness levels.

Because the electrochromic film that coats the sidewalls of the nanograting is so thin, it’s very easy for electrons to make their way through and change its opacity,” Agrawal says. “The slits are much narrower (about 60nm) than the wavelengths of light they are transmitting (from about 400 to 700nm). This forces the incoming light to cling to the interface between the metal and the electrochromic layer on its way down the slits. And because the grating is so much deeper (about 250nm) than it is wide, and the walls of the slits are coated with electrochromic polymer all the way down, it can reduce the light’s intensity to the same degree as if the light were passing through a much thicker layer of electrochromic film, enabling a great amount of control.

Amit Agrawal, Co-Lead Author

NIST Fellow Henri Lezec, an author of the paper, said that the present setup at NIST utilizes a liquid electrolyte in order to facilitate an appropriate electron flow. Iit is not suitable for manufacturability and reliability. A compact and more physically stable solid-state electrolyte could be used an alternative to this liquid electrolyte.

According to Alec Talin, a co-author based at Sandia National Laboratories, the next step is applying this principle to develop reflective, sunlight-readable displays, that do not need an energy-intensive backlight.

This research work was conducted at NIST’s Center for Nanoscale Science and Technology (CNST), which provides support to the U.S. nanotechnology enterprise right from discovery to production by offering access to modern nanoscale measurement techniques, fabrication methods and technology to academia, industry, and governmental agencies including NIST.

The study result have been reported in Nature Communications.