Apr 13 2016

Concrete, the commonly used construction material all over the world, is a key contributor to climate change. As a result, scientists from Rice University have suggested that it is important to know every detail about it's manufacturing process.

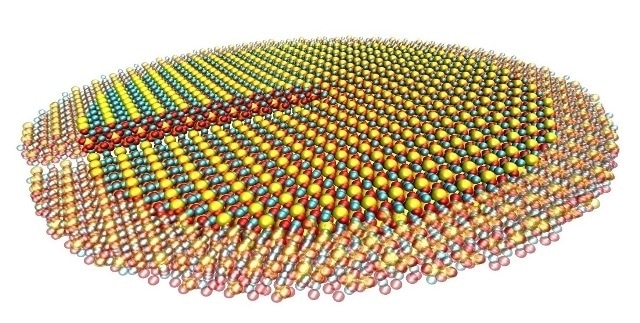

A computer model shows tricalcium silicate with a defect known as a screw dislocation, which influences the brittle properties of the crystal structure. The atoms on the periphery are faded because they are little affected by the dislocation core at the center of the disc. Illustration by Lei Tao

A computer model shows tricalcium silicate with a defect known as a screw dislocation, which influences the brittle properties of the crystal structure. The atoms on the periphery are faded because they are little affected by the dislocation core at the center of the disc. Illustration by Lei Tao

The Rice lab of Rouzbeh Shahsavari, a theoretical physicist, is probing these details at the atomic level. The lab has released the results, obtained from computer modeling studies, which explain in detail how dislocations such as screw-like defects, seen in raw crystals used for concrete, affect the efficiency of the concrete manufacturing process.

The research featured in this month’s issue of the Journal of the American Ceramic Society explain that tricalcium silicates (C3S) comprising of pure rhombohedral crystals are best suited to develop “clinkers.” Round lumps of C3S are known as clinkers that when ground into a powder, mix with water to make cement. Cement is the glue that is capable of holding gravelly concrete. A manufacturer will require less energy to grind the clinkers when they are easier to grind.

Last year, the Shahsavari lab informed that hot clinkers were relatively easier to grind. The researchers also considered the detrimental effects of screw dislocations and analyzed how the resulting powder merges with water.

The lab developed computer models depicting the molecular structures that represent a number of commonly used varieties of C3S to identify those that are likely to be more fragile, in spite of the unavoidable dislocations that twist the crystals, resulting in unpredictable formations.

The lab also made efforts to understand how defects found in the microscopic crystals impact the ability of the powder to react with water. The researchers discovered that rhombohedrals are more reactive to water when compared to the two monoclinic clinkers under study. Rhombohedral crystals have the same length edges unlike monoclinic crystals, whose edges are of varied lengths.

Understanding and quantifying the structure, energetics and the effect of defects on mechanics and reactivity of cement crystals is a fundamental and engineering challenge. This work is the first study that puts an atomistic lens on the key characteristics of screw dislocations, a common line defect in C3S, which is the main ingredient of Portland cement.

Rouzbeh Shahsavari, Theoretical Physicist, Rice University

Shahsavari highlighted the importance of maximizing the usage of energy when producing concrete. This point was also supported by participants of the 2015 climate summit in Paris. Shahsavari pointed out that the annual global production of over 20 billion tons of concrete contributes 5 to 10% of carbon dioxide to worldwide emissions, exceeded only by energy generation and transportation as a greenhouse gas producer.

Shahsavari stated that the study also examines other defects that include twinning deformations, brittle-to-ductile transitions, and edge dislocation in cement. All of the findings offer new strategies and insights that will help to enhance the reactivity and grinding energy of cement, which is capable of reducing the carbon dioxide footprint and energy usage related to concrete.

Co-authors of the paper are Rice graduate student Lei Tao and alumna Lu Chen, currently a structural engineer at Arup. Shahsavari is an assistant professor of civil and environmental engineering and of materials science and nanoengineering.

The research was supported by the National Science Foundation.