Nov 24 2016

With three new additives, BrüggemannChemical (www.brueggemann.com) allows the extension of the properties of anionically polymerized AP-NYLON® cast polyamides. BRUGGOLEN® TP-C1608 is a particularly efficient heat stabilizer that enables, for the first time, long-term service temperatures of up to 150 °C. BRUGGOLEN® TP-C1312 has been developed to raise impact strength, while the delaying activator BRUGGOLEN® C25 can be used to not only facilitate the casting of parts with large dimensions and/or small wall thicknesses but also to simplify the production of high-quality composites.

Long-term service temperatures up to 150 °C

The new BRUGGOLEN® TP-C1608 heat stabilizer raises the long-term service temperature of the final parts from 120 °C – which was previously regarded as the limit for cast polyamide – to 150 °C. At the same time, it significantly reduces aging across the whole temperature range. In extensive tests carried out at 150 °C, AP-NYLON® components retained more than 50% of their tensile strength after 500 hours. BRUGGOLEN® TP-C1608 can be added to existing formulations of AP-NYLON®.

With the development of this stabilizer, BrüggemannChemical is supporting the automotive driven trend towards lightweight construction and extending it to other industrial applications which are exposed to high temperature conditions. Cast polyamide can thus replace heavy metal parts and even entire subassemblies all of which benefit from its inherent excellent damping properties and high corrosion resistance and which now can also be subjected to increased temperatures. Furthermore, AP-NYLON® heat-stabilized with BRUGGOLEN® TP-C1608 also extends the possible applications for prototype moldings. One example is a complete automotive intake manifold produced via an inexpensive silicone mold which was evaluated prior to commercial production.

BRUGGOLEN® TP-H1606 is another heat stabilizer recently launched by BrüggemannChemical based on the similar technology. It has been developed for the modification of polyamide 6 and polyamide 66 compounds for injection molding and extrusion applications.

Increased cost-efficiency and toughness

In cases where the basic toughness of AP-NYLON® is inadequate and the very high impact strength of the NYRIM® polyamide 6 block copolymers exceeds requirements, the new BRUGGOLEN® TP-C1312 impact modifier from BrüggemannChemical provides the ideal solution. By varying the dosage of the additive and thus the elastomer content (between 3 % and 20 %), it makes it possible to accurately adjust the impact strength to the demands of the application. In this way, polymers modified with BRUGGOLEN® TP-C1312 bridge the gap, in terms of cost and performance, between unmodified cast polyamides and highly impact resistant NYRIM®.

Modification with BRUGGOLEN® TP-C1312 also reduces the hardness of molded parts to between 80 and 60 Shore D, so that, for example, rollers can run more softly and thus more quietly. With semi-finished products any tendency to fracture is reduced during machining. All applications benefit from virtually streak free moldings because of the very homogeneous dispersion of the elastomer phase in the AP-Nylon® matrix.

Delayed activation

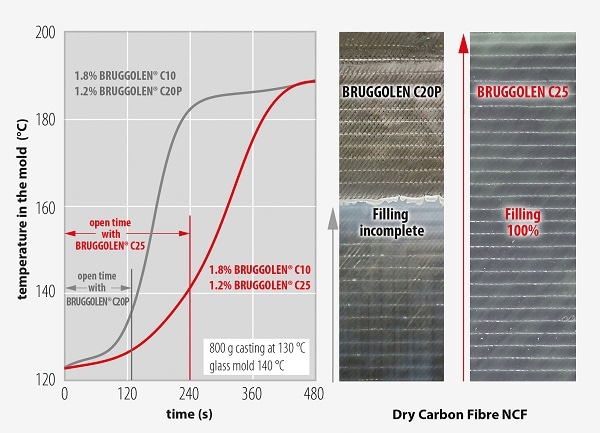

BRUGGOLEN® C25 is a new delaying activator for AP-NYLON®. It slows down the polymerization process compared to the standard grade, BRUGGOLEN® C20P. Whereas the open time (transition from liquid to solid phase) of the standard is between 1 and 5 min, times of 2 to 10 min can be attained with the new BRUGGOLEN® C25. This is a particular advantage with parts of large dimensions, one with small wall thicknesses and those with complex geometries, as, together with more time for the equipment operators, it allows initially entrapped bubbles enough time to rise completely to the surface. Above all, BRUGGOLEN® C25 also makes the manufacture of high-grade, two-dimensional, glass or fabric-reinforced composites easier. At the product development phase, it also permits parts to be filled more slowly so as to be able to study and optimize the processes.

As far as processing is concerned, the additive does not require any change to the temperatures of the polymer and mold. The mechanical properties of the resulting polymers are similar, although the BRUGGOLEN® C25 is characterized by a slightly yellowish color.