Nov 24 2016

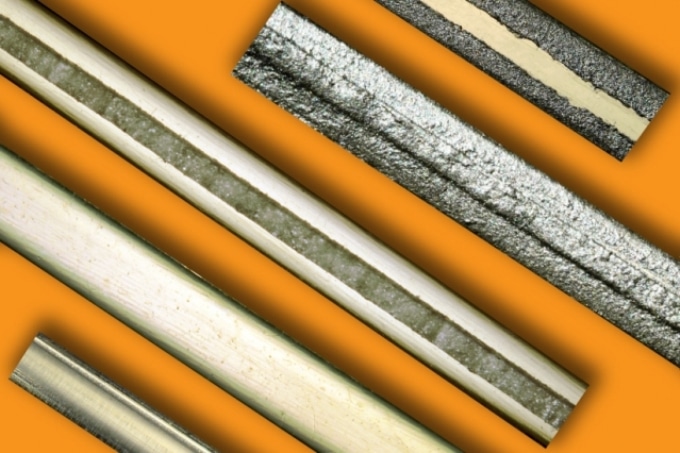

This image shows the fabrication steps from raw circular filament to a fully functional bending artificial muscle. The bottom filament is a raw circular filament. Researchers press the filament using a rolling mill (the second sample from the bottom). Next, they add a mask in the middle of the surface (the third sample from the bottom). Then, they add the conductive ink (the second sample from the top). Finally, they remove the mask after the ink is dried (the sample on the top). (Image: Felice Frankel and Seyed Mohammad Mirvakili)

This image shows the fabrication steps from raw circular filament to a fully functional bending artificial muscle. The bottom filament is a raw circular filament. Researchers press the filament using a rolling mill (the second sample from the bottom). Next, they add a mask in the middle of the surface (the third sample from the bottom). Then, they add the conductive ink (the second sample from the top). Finally, they remove the mask after the ink is dried (the sample on the top). (Image: Felice Frankel and Seyed Mohammad Mirvakili)

Artificial muscles - materials that contract and expand in a similar manner like muscle fibers do - can have many applications, from robotics to components in the aviation and automobile sectors. Recently, a team of MIT researchers have developed one of the simplest and economical systems yet to create such “muscles,” in which a material recreates a few of the bending motions that natural muscle tissues perform.

The main ingredient is ordinary nylon fiber, which is cheap and ubiquitous.

The new method to harness this common synthetic fiber material depends upon heating and shaping the fibers in a specific way. The method is described in a new paper in the Advanced Materials journal by Seyed Mirvakili, a doctoral candidate, and Ian Hunter, the George N. Hatsopoulos Professor in the Department of Mechanical Engineering.

Previously, researchers had developed the basic principle of using twisted coils of nylon filament to imitate basic linear muscle activity. They demonstrated that for a given weight and size, such devices could extend and retract further and store and discharge more energy than natural muscles.

But bending motions, such as those of human limbs and fingers, proved more challenging and had not yet been accomplished in a simple and inexpensive system until the new work at MIT.

There are some exisiting materials that can be used to create these kinds of bending motions, which could be useful for some tactile displays or biomedical devices. However, those are likely to use “exotic materials to do the job, and they are very expensive and very difficult to make,” Mirvakili says.

For example, carbon nanotube yarns can provide great longevity (over a million linear contraction cycles) but are still too expensive for widespread adoption, and shape-memory alloys offer a strong contracting pull but have a poor cycle life (less than 1,000 cycles).

Cheap and Simple

In contrast, the new nylon-based system uses inexpensive material and a simple manufacturing process, and displays excellent cycling longevity. It all depends on how the nylon fibers are shaped.

Certain polymer fiber materials, including highly oriented nylon, have an odd property: When heated, “they shrink in length but expand in diameter,” Mirvakili says, and this property has been harnessed to manufacture some linear actuator devices.

But to convert that linear shrinking motion into bending usually requires a mechanism such as a takeup reel and a pulley, adding complexity, extra size, and expense. The MIT research team’s advance was to directly harness the motion without requiring additional mechanical parts.

One of the downsides on linear actuators created from such materials is that after being heated to activate the contraction, they take a while to cool back down.

The cooling rate can be a limiting factor, but I realized it could be used to an advantage.” Selectively heating one side of the fiber, he says, causes that side to begin contracting faster than the heat can penetrate to the other side, and thus can produce a bending motion in the fiber. “You need a combination of these properties,” he says: “high strain [the pull of the shrinking motion] and low thermal conductivity.

Seyed Mirvakili, Doctoral Candidate, MIT

To make this system worked effectively as an artificial muscle, the fiber’s cross-section has to be carefully shaped. The team used an ordinary nylon fishing line to begin with, and compressed it to alter its cross-section from round to square or rectangular. Then, selectively heating one side caused the fiber bending in that direction.

Changing the direction of the heating could also generate more complex motions; in their lab tests, the team used this heating method to obtain the fibers to move in figure-eights and circles, and much more complex patterns of movement could easily be accomplished, they say.

A variety of heat sources can be used on the fibers, including chemical reactions, electric resistance heating, or a laser beam that shines on the filament. For a few of their tests, the team used a special conductive paint coated on the fibers and held in place using a resin binder; when a voltage was applied to the material, it selectively heated the portion of the fiber immediately below the paint, causing the fiber to bend in that direction.

Long-lived Material

The MIT researchers have shown that the material can sustain its performance for no less than 100,000 bending cycles, and can bend and retract at a speed of at least 17 cycles per second.

Hunter recommends that eventually, applications for such fibers might include clothes that contract to bend snugly to the contours of the body, significantly decreasing the number of different sizes a manufacturer would need to make, while enhancing the fit and comfort. Or, the fibers might be applied in shoes that would contract themselves when put on or regulate their shape and stiffness during each stride.

The system could also allow for self-adjusting catheters or other biomedical devices. Going forward, it could even pave the way for mechanical systems such as vehicle exterior panels that change their aerodynamic shape to adapt to alterations in wind and speed conditions, or automatic tracking systems for solar panels that would use surplus heat produced by the panels themselves to maintain the panels facing the sun.

[This Technique] is novel and elegant, with very good experimental data supported by appropriate physics-based models. This is a simple idea that works really well. The materials are inexpensive. The manufacturing method is simple and versatile. The method of actuation is by simple electrical input. The bending actuation performance is impressive in terms of bending angle, force generated, and speed. Bending-type actuators are needed for robotic grippers, microscopic tools, and various machine components. These new bending actuators could have immediate application.

Geoffrey Spinks, Professor, University of Wollongong

These are “exciting and game-changing findings,” adds Andrew Taberner, an associate professor of bioengineering at the University of Auckland in New Zealand, who also was not involved in this research. “One can imagine many applications for this type of actuator in the medical and instrumentation fields,” he says. “I expect that this work will become highly cited.”

Seyed Mirvakili was supported by the Natural Sciences and Engineering Research Council of Canada.

Muscles made of nylon

MIT researchers have come up with one of the simplest and lowest-cost systems yet for developing artificial muscles, in which a material reproduces some of the bending motions that natural muscle tissues perform. The key ingredient? Nylon fiber. (Video credit: Melanie Gonick/MIT)