Dec 1 2016

Safran Landing Systems, Metalysis, the University of Strathclyde’s Advanced Forming Research Centre (AFRC) and the University of Sheffield are the partners working on the FASTForge project.

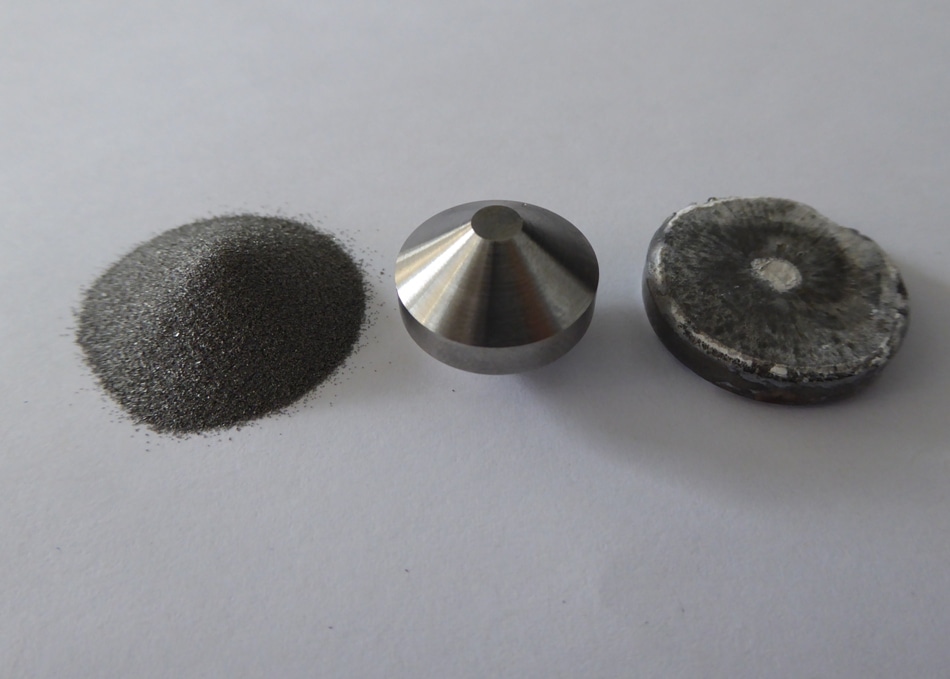

FASTForge aims to cut cost to a third of current price of titanium components (Image copyright © Mercator Media 2016)

FASTForge aims to cut cost to a third of current price of titanium components (Image copyright © Mercator Media 2016)

Through this project the consortium is aiming to produce novel titanium alloy aerospace components in three steps from rutile sand - a mineral composed primarily of titanium dioxide (TiO2).

Michael Ward, chief technology officer at the AFRC, said: “The cost of titanium is an important issue in the aerospace industry. Cheaper titanium from the FAST-forge process will protect the UK’s position as the second-largest global aerospace manufacturer, with potential to grow our share of the market as the sector grows over the next 20 years.”

“It will mean the supply chain staying and expanding in the UK with more high-value jobs as a result.”

The aim is to develop a novel low cost titanium forging production process, unique to the UK. The production of this aerospace grade titanium at an affordable price will be an enabler for the introduction of more titanium on aerospace components.

It will seek to develop the raw material process, establish how it can be embodied in a new UK supply chain, develop cost effective manufacturing techniques and prove the capability in a landing gear application.

Ultimately, the cost of titanium components could be reduced to less than a third of the current price.

“The FAST-forge process offers an exciting opportunity to reduce the costs and environmental impact of titanium production,” explained Sam Evans from Safran Landing Systems.

He added: “This project has the potential to diversify the supply chain of titanium, allowing its use to continue in current products, as well as allowing its introduction into areas where it has not previously been feasible.”

“This will provide a competitive advantage to the UK high value manufacturing and aerospace industry.”

Each company has a distinct role in the project, Safran Landing Systems will manage the project, provide the specifications for the component, test it and assess where else the process could be applied to their products. Metalysis will create the powder titanium alloy from the rutile sand.

The AFRC, one of the seven elite centres which make up the High Value Manufacturing Catapult, and the University of Sheffield will model the manufacturing process steps and optimise the preform and forging die designs to minimise the material used in the end product.