Dec 2 2016

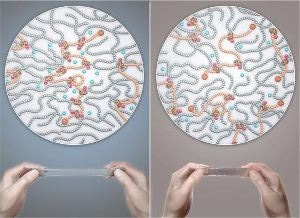

The polymer gels, which were prepared using polyrotaxane (PR) cross-linkers of different molecular weights but the same number of cross-linking points per unit volume of gel, have almost the same Young’s modulus. By contrast, the extensibility and rupture strength of the polymer gels are substantially increased with increasing molecular weight of the PR cross-linker. Credit: http://en.nagoya-u.ac.jp/

The polymer gels, which were prepared using polyrotaxane (PR) cross-linkers of different molecular weights but the same number of cross-linking points per unit volume of gel, have almost the same Young’s modulus. By contrast, the extensibility and rupture strength of the polymer gels are substantially increased with increasing molecular weight of the PR cross-linker. Credit: http://en.nagoya-u.ac.jp/

An international research team from Nagoya University and The University of Tokyo have developed a new method to strengthen polymer gels by altering the length of polymer “thread” per molecular “bead”.

A polymer gel is made of a three-dimensional cross-linked polymer network packed with liquid molecules. Yet, most of the traditional polymer gels are brittle. This is because the concentration of stress takes place easily in their cross-linked polymer network structure. To enable the polymer gels to be used as, for instance, superabsorbent materials and molecular sieves, their mechanical properties need to be improved.

The researchers have developed a new method that involves using a design based on polymer “threads” and molecular “beads” to enhance the fracture resistance of polymer gels. The molecular beads are modified cyclodextrin rings threaded onto polyethylene glycol (PEG) threads.

These rings contain groups that enable cross-linking of the threaded structures to form a three-dimensional polymer network that is capable of being used as a polymer gel. The outcomes of the research were recently reported in ChemComm.

We investigated the effect of the molecular weight of PEG per cyclodextrin ring on the strain and rupture strength of the resulting gels.

Yukikazu Takeoka, Study Coauthor

The researchers found that their polymer gels are resistant to fracture because when force is applied, the cyclodextrin beads can slide across the PEG threads, preventing stress concentration.

The molecular weight of PEG per cyclodextrin ring increases with the magnitude of this effect, producing gels that have greater strain and rupture strength. The increase in the length of thread between the beads enables the cyclodextrin beads to easily slide along the polymer threads.

The ability to improve the fracture resistance of polymer gels by increasing the molecular weight of polymer units for each cross-linking cyclodextrin ring is a convenient solution to overcome the problem of the brittleness of conventional polymer gels.

Kana Ohmori, Lead Author of Study

This technique of enhancing the strain and rupture strength by making use of mobile cross-linking molecular beads threaded on polymer chains may also enable the development of polymer gels with desired mechanical properties.