Mar 24 2017

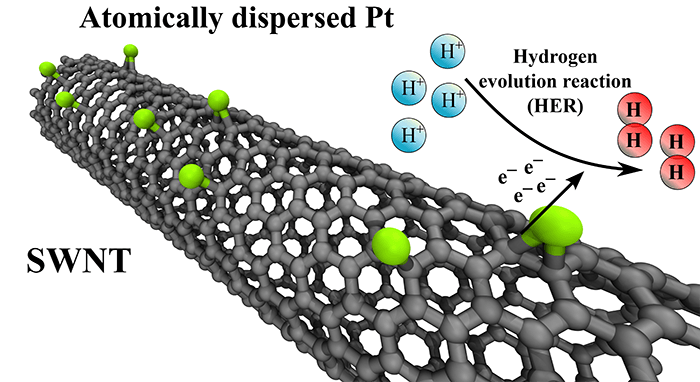

DFT (density functional theory) suggests that carbon nanotubes stabilize single platinum atoms and that hydrogen evolution reaction takes place more efficiently on their surfaces, compared to conventional platinum nanoparticles. Credit: Aalto University

DFT (density functional theory) suggests that carbon nanotubes stabilize single platinum atoms and that hydrogen evolution reaction takes place more efficiently on their surfaces, compared to conventional platinum nanoparticles. Credit: Aalto University

Platinum is considered to be one of the bottlenecks hindering the growth of renewable energy as it is an extremely expensive metal. Electrolyzers that store electric energy as chemical compounds use platinum as the catalyst. Additionally, platinum plays a vital role in catalytic converters, fuel cells and many chemical processes employed in the industry.

Professors Tanja Kallio and Kari Laasonen headed a team of Aalto University researchers who developed a manufacturing method for electrocatalysts that uses only one hundredth of the amount of platinum usually used in commercial products. The activity accomplished using the new material is similar to that of commercial electrocatalysts. The method is based on the unique characteristics of carbon nanotubes.

When platinum is electrodeposited on the surface of carbon nanotubes, it forms particles consisting of a couple of atoms. On other materials, such as graphene, platinum forms larger nanoparticles. We believe this is because the carbon atoms of the curved surface are in a strained state, which makes them prone to stabilising platinum on the surface of the nanotube. This ensures that the platinum atoms form small and catalytically active particles. Our modelling showed that the more strained the carbon bonds are, the better the stabilisation of the platinum. Smaller tubes are more curved, which makes the strain greater, so the diameter of the nanotubes is also important.

Tanja Kallio, Professor, Aalto University

One Third of the Price

Electrical energy is stored in the form of hydrogen bond energy by electrolyzers. This mechanism is used to store fluctuating energy, such as wind energy. It also helps in balancing the difference between production and demand. The process will become significantly less expensive when the amount of platinum needed is reduced, since approximately one third of the price of the electrolyzer is formed by the electrocatalyst.

In addition to the price of platinum, the availability of the metal is also a problem. Platinum is on the EU list of critical raw materials, which means that its use is problematic either due to its scarceness or due to geopolitical problems. This is why the EU is aiming to reduce the use of platinum. In small-scale conditions and at room temperature, the electrocatalyst is stable and usable for a long time. The next step is to increase the scale of production and test the functionality of the electrocatalyst in practical applications, which are often carried out at a higher temperature.

Tanja Kallio, Professor, Aalto University

Kallio emphasizes that until now the functionality of the electrocatalyst developed at Aalto University has only been established in laboratory conditions.

Results obtained from this research were recently published in the scientific journal ACS Catalysis.