May 31 2017

A new advance on a method formulated by MIT Researchers could enable continuous, high-precision monitoring of materials exposed to a high-radiation environment. The technique may allow these materials to last much longer, removing the need for preventive replacement. It could also accelerate the search for new and better materials for these challenging environments.

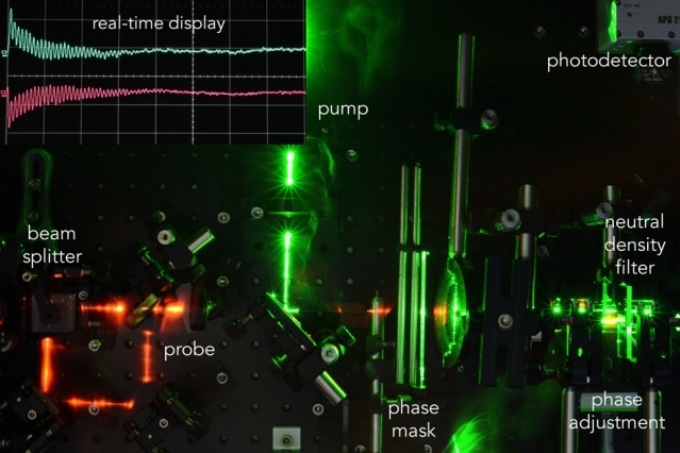

“Our whole goal was to monitor how materials evolve when exposed to radiation,” associate professor Michael Short explains, “but do it in a way that’s online,” without requiring samples to be extracted from that environment and tested in outside devices. (Courtesy of the researchers)

“Our whole goal was to monitor how materials evolve when exposed to radiation,” associate professor Michael Short explains, “but do it in a way that’s online,” without requiring samples to be extracted from that environment and tested in outside devices. (Courtesy of the researchers)

The latest findings are reported in the Applied Physics Letters journal by Graduate Student Cody Dennett and Assistant Professor of Nuclear Science and Engineering Michael Short. This research develops on the team’s previous work that described the benchmarking of the technique, called transient grating spectroscopy (TGS) for nuclear materials. The new research reveals that the method can certainly perform with the high degree of sensitivity and time-resolution that the previous calculations and tests had suggested, should be viable for detecting minute imperfections.

Our whole goal was to monitor how materials evolve when exposed to radiation, but do it in a way that’s online.

Michael Short, Assistant Professor of Nuclear Science and Engineering, Massachusetts Institute of Technology

Without necessitating samples to be extracted from that environment and analyzed in outside devices. Such a process can be expensive and time-consuming, and does not provide information regarding how damage happens over time.

The new testing method can expose changes in, for instance, mechanical and thermal properties that impact the material’s response to temperature surges or vibration. “What we’re working toward is a real-time diagnostic system that works under radiation conditions,” Short says.

Their previous work, he says, demonstrated that the method was capable of detecting such radiation-induced alterations. The new research, which included making a few modifications to the technique, allows measurements to be taken at high speed under real-time, dynamic conditions and to create the kind of comprehensive information required for a practical monitoring system.

The technique functions without the need for any physical contact between the monitoring device and the metal surfaces being monitored. Instead, it depends mainly on optical probes, which employ one set of laser beams to trigger vibrations in the surface and others to probe the properties of those vibrations by using the interference patterns of the beams, which can expose details of not only the surface properties but also of the bulk material.

The method could also have a wide range of applications in monitoring other kinds of materials, the Researchers say. For instance, it could be used to monitor the performance of phase-change materials that are being created for new kinds of magnetic data storage.

The ability to do characterization of dynamically changing systems is of interest to a wider materials processing community.

Cody Dennett, Graduate Student, Massachusetts Institute of Technology

As the team published details of the early work, Researchers worldwide have contacted the Researchers with offers to help with applying the method to various kinds of materials and environments.

“We have particular applications in mind for our next steps,” Dennett says, “but the relative ease of implementation should make it interesting to a wide range of Materials Scientists.”

Compared to current techniques of examining these radiation-induced materials’ alterations, which involve using a number of samples exposed over long periods of time prior to testing, Short says, this method can provide,“More data from one sample, in one experiment, in about 1 percent of the time.”

That ability to perform quick testing could be a great benefit for those trying to create new materials for new generations of nuclear reactors, Dennett says. At present, such development is a slow and cumbersome process, because even small changes in the relative percentages of diverse alloying metals can intensely affect the material’s properties. The ability of the new method to provide fast, real-time answers could pave the way for much broader possibilities for creating and refining new options.

There are a lot of groups working on more radiation-resistant alloys, but it’s a long process. Instead, this allows you to make a lot of variations and test them as you go.

Michael Short, Assistant Professor of Nuclear Science and Engineering, Massachusetts Institute of Technology

This technique could allow these Researchers to derive important characterization data on new materials,“In weeks instead of years,” Short says.

The National Science Foundation, the U.S. Department of Energy’s National Nuclear Security Administration, and the MIT-Singapore University of Technology and Design International Design Center supported the research.