Nov 30 2017

Researchers at the Department of Energy's Pacific Northwest National Laboratory, along with experts from industry and academia, have developed predictive engineering tools for designing new, economical, and lightweight automotive composites. This approach should speed the development of more economical carbon fiber materials.

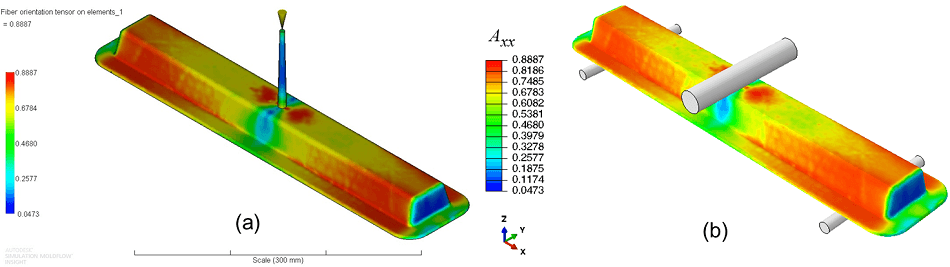

Fiber orientation prediction in 3D complex part using the Autodesk software (Left) that was imported into the 3D ABAQUS® model (Right) for stiffness performance prediction using the PNNL-developed Eshelby-Mori-Tanaka Approach to Non-Linear Analysis (EMTA-NLA) model in ABAQUS®

Fiber orientation prediction in 3D complex part using the Autodesk software (Left) that was imported into the 3D ABAQUS® model (Right) for stiffness performance prediction using the PNNL-developed Eshelby-Mori-Tanaka Approach to Non-Linear Analysis (EMTA-NLA) model in ABAQUS®

Lower cost, lighter weight materials are needed for improved fuel efficiency. By model year 2025, U.S. regulations mandate that the average fuel economy standard meets 54.5 miles per gallon, a 60 percent improvement over the 35.5 mpg required now.

While stronger and lighter than steel, carbon fiber composites are relatively expensive. For widespread adoption to occur, new, economical composites that meet mechanical and safety requirements — such as long carbon fiber-reinforced thermoplastic resins like polypropylene and nylon — need to be developed. Rather than building molds, molding parts, and testing new composites, computer modeling can speed the process. Using the engineering software validated by the PNNL-lead team, manufactures will be able to "see" what the structural characteristics of proposed carbon fiber composites designs would be like before they are molded.

As part of the project, PNNL also analyzed the costs of long carbon fiber components versus standard steel and fiberglass composites. PNNL found the carbon fiber reinforced polymer composite technology studied could reduce the weight of automobile body systems by over 20 percent.

PNNL partnered on the project with:

automotive manufacturer Toyota

tier one part producer Magna

long carbon fiber material and technology supplier PlastiComp

process modeling software provider Autodesk

university research partners University of Illinois, Purdue University, and Virginia Tech

Read more about the predictive engineering project in this PNNL highlight.