Dec 4 2017

Researchers of KIT have used 3D printers for the microrange and successfully developed a metamaterial from cubic building blocks responding to compression forces by a rotation. Generally, this can only be attained by transmission with the help of a crankshaft, for example.

The sophisticated design of ring structures and bars and the fundamental mathematics have now been presented in the recent issue of Science.

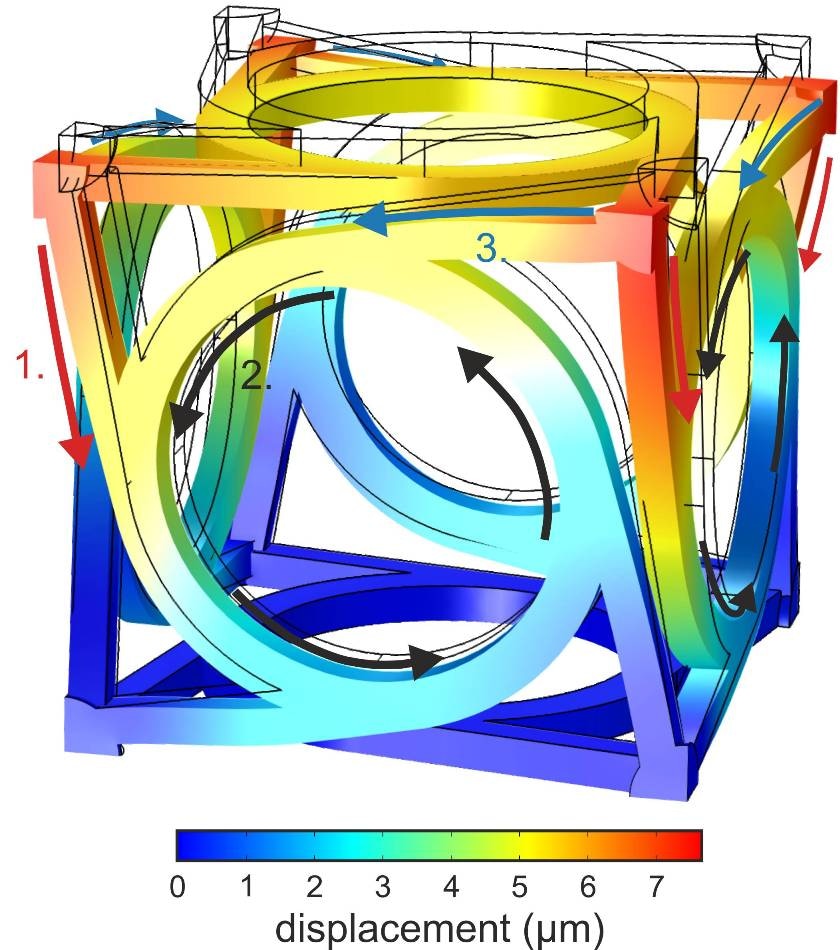

Forces from above are transmitted to the vertical ring structures via bars. The rotation of the rings exerts forces onto the corners of the horizontal planes of the cube. (T. Frenzel/KIT)

Forces from above are transmitted to the vertical ring structures via bars. The rotation of the rings exerts forces onto the corners of the horizontal planes of the cube. (T. Frenzel/KIT)

“If a force is exerted from above onto a material, the latter deforms in various ways. It may be bulged, compressed, or bent,” states Martin Wegener, Professor of the Institute of Applied Physics and Director of the Institute of Nanotechnology of KIT. “According to the valid rules of mechanics, however, it will not rotate,” he adds. However, his staff member Tobias Frenzel and colleagues have presently succeeded in designing a filigree cubic structure capable of reacting to loading by a rotation around its axis.

"By means of a computer simulation, we first developed a design with this new mechanical property that has not been described so far,” Frenzel, the first author of the study, explains. “Our calculations revealed that the desired behavior is shown by a complex chiral structure, i.e. a structure that cannot be mapped to its mirror image, similar to the left and the right hand.”

The filigree cubes that have been calculated by Frenzel and his team comprise of rings and bars that are connected to each other in a specific pattern.

The arms that connect the ring structures with the corners of the cube move vertically downwards under load. This movement leads to a rotation of the rings, these rotation movements, in turn, transmit forces to the corners of the horizontal planes of the cube, such that the complete structure starts to twist around its axis.

Tobias Frenzel, Institute of Nanotechnology of KIT

This was followed by the team producing towers of the above cubic structures of variable sizes, pieces, and strengths by employing a 3D microprinting method recognized at KIT. The edge length of the cubes was observed to range from 100 to 500 µm. The researchers developed towers of 4 to 500 cubes and 2 mm height. In order to check their theory, the researchers also constructed towers of achiral cubes, referring to cubes capable of being mapped to their mirror image.

The scientists discovered that towers arranged from chiral blocks began to rotate around their axis under the influence of force. “We measured a rotation by up to two degrees per percent of deformation,” Frenzel says. The towers developed from achiral cubic structures failed to exhibit this rotation. The researchers also discovered that the stiffness of the towers increased along with the number of cubes, despite the fact that the dimensions of the separate components decreased proportionally.

Tobias Frenzel states that there is still a far way to reach application. The team’s earlier studies of elastic “invisibility cloaks” inspired the work. It could be possible to use these for buffering shock waves of earthquakes or diverting them around historic buildings.