Graphene has, since its discovery in 2004, been touted as a wonder material capable of revolutionizing many different industries. The material is light, robust, transparent and electrically conductive. It is also good at converting heat to electricity – a property now being exploited in radiation detection.

Image credit: Egorov Artem/shutterstock

Image credit: Egorov Artem/shutterstock

Researchers from the Chalmers University of Technology in Sweden have taken advantage of the thermoelectric properties of graphene to make a new kind of radiation detector. Classed as a bolometer - a device which measures the power of incident electromagnetic radiation via heating of a material with a temperature dependent electrical resistance - the researchers' prototype has a fast response time, works over a wide range of temperatures and could easily be scaled up at a relatively low cost, making it commercially attractive.

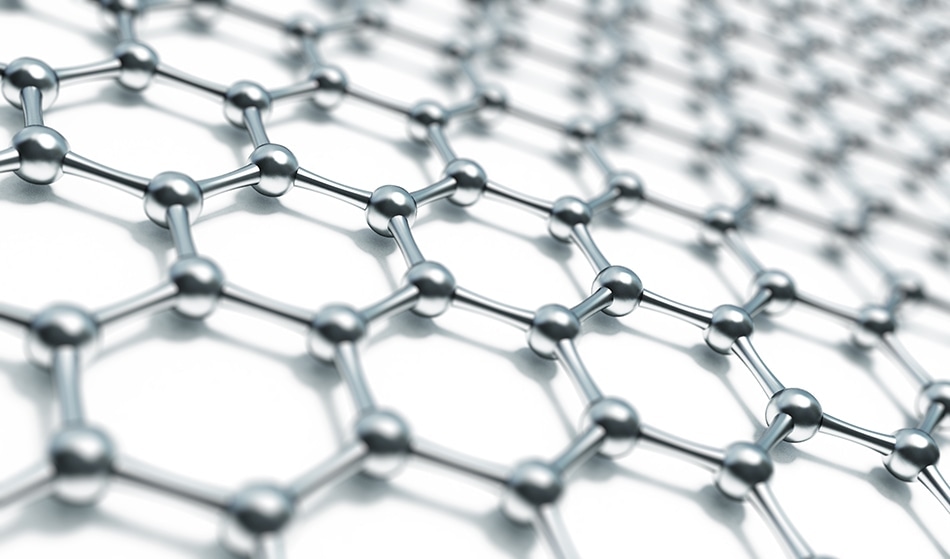

Since it was first isolated in Manchester in 2004, graphene – a single sheet of carbon atoms arranged in a flat, hexagonal lattice structure – was expected to usher in a new type of technology, but has been mainly utilized for its mechanical properties.

Unfortunately, there are some strong fundamental limitations for this material. Nowadays, the real industrial applications of graphene are quite limited. But our device shows that more fundamental properties can be used in actual applications.

Grigory Skoblin, Ph.D. student - Quantum Device Physics Laboratory Faculty, Chalmers

The new bolometer makes use of graphene's thermoelectric property – radiation heats part of the device, causing electrons to move. These displaced particles generate an electric field, which in turn produces a voltage difference across the device. The change in voltage is in effect, a direct measurement of the radiation.

"We used a split top gate to create a p-n junction in the graphene, thereby making an effective thermocouple to read out the electronic temperature in the graphene," the team write in Applied Physical Letters. "The electronic temperature is increased due to the AC currents induced in the graphene from the incoming radiation, which is first received by an antenna and then directed to the graphene via the top-gate capacitance. Except for the constant DC voltages applied to the gate, the detector does not need any bias and is therefore very simple to use."

Other devices are reliant upon the creation of an electrical current or resistance change by incoming radiation but at the moment, measuring the change in current or resistance requires an external source of power to generate the initial current.

This new device is much more straightforward, says Skoblin. The piece of graphene within the bolometer is small, making it one of the fastest models of its type because it heats up and responds quickly. The device also remains sensitive to radiation at temperatures up to 200°C, whereas traditional bolometers work only at cryogenic temperatures to enable higher sensitivity.

Past research has seen bolometers created with better properties than Skoblin's, but these models utilize a double layer of graphene, which makes them harder to scale up, explains the researcher.

Another advantage of the new detector is its coating, which the researchers had previously developed. The graphene is coated with the dielectric polymer Parylene – a trade name for a number of chemical vapors deposited poly(p-xylylene) polymers used as moisture and dielectric barriers – which offers a good balance of performance and scalability. Skoblin says that better performance can be achieved by coating graphene with hexagonal boron nitride, but this substance is hard to acquire, and the coating techniques are challenging to scale up. Other studies have also suggested that a bolometer with this coating would be less efficient.

This prototype bolometer currently only works with microwave radiation at 94 gigahertz, but future designs will aim to widen this frequency range. Skoblin's next step is to construct the device using chemical vapor deposition to grow large pieces of graphene thus paving the way for mass production.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.