Apr 23 2018

Researchers from the University of Connecticut have developed a biodegradable composite composed of silk fibers that can be used to mend broken load-bearing bones without the complications occasionally caused by other materials.

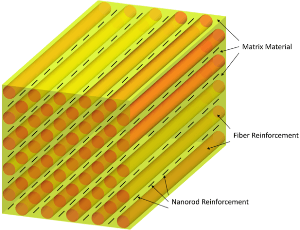

A 3D rendering of a novel bone-fixing composite developed at the University of Connecticut. The composite is made of silk fibers and fibers of polylactic acid that are coated with fine bioceramic particles to add strength while maintaining flexibility. The biodegradable composite helps heal bones without the complications posed by metal parts. (Image credit: Bryant Heimbach/UConn)

A 3D rendering of a novel bone-fixing composite developed at the University of Connecticut. The composite is made of silk fibers and fibers of polylactic acid that are coated with fine bioceramic particles to add strength while maintaining flexibility. The biodegradable composite helps heal bones without the complications posed by metal parts. (Image credit: Bryant Heimbach/UConn)

Repairing crucial load-bearing bones such as those located in the leg can be a long and painful process. In order to facilitate repair, doctors may incorporate a metal plate to support the bone as it fuses and heals.

Yet, that can be tricky. Some metals leach ions into nearby tissue, resulting in inflammation and irritation. Metals are also extremely stiff. If a metal plate bears excess load in the leg, this could cause the new bone to grow back weaker and be susceptible to fracture.

In search of a solution to the issue, UConn professor Mei Wei (a materials scientist and biomedical engineer) looked to moths and spiders for inspiration. Specifically, Wei concentrated on silk fibroin, a protein in the silk fibers spun by spiders and moths known for its tensile strength and toughness.

Silk fibroin is well-known in the medical community. It is a common component in medical sutures and tissue engineering due to its biodegradability and strength. Yet no attempt has been made to create a dense polymer composite out of it, and that is what Wei realized she needed if she was going to design an optimized device for healing broken load-bearing bones.

Wei’s lab, working with UConn associate professor Dianyun Zhang, a mechanical engineer, started testing silk fibroin in a variety of composite forms, looking for the exact combination and proportion of different materials to attain optimum flexibility and strength. The new composite definitely needed to be robust and stiff, yet not so much so that it would hinder dense bone growth. Simultaneously, the composite must also flexible, allowing patients to preserve their natural range of motion and mobility while the bone healed.

After several tests, Wei and Zhang found the materials they were seeking. The new composite contains long silk fibers and fibers of polylactic acid - a biodegradable thermoplastic resulting from sugar cane and cornstarch - that are dipped in a solution in which each is coated with fine bioceramic particles composed of hydroxyapatite (the calcium phosphate mineral found in bones and teeth). The coated fibers are then packed in layers on a small steel frame and forced into a dense composite bar in a hot compression mold.

Wei reports in a research paper recently published in the Journal of the Mechanical Behavior of Biomedical Materials, that the high-performance biodegradable composite displayed flexibility and strength properties that are among the highest ever recorded for analogous bioresorbable materials in literature.

It is possible that they could get even better.

“Our results are really high in terms of strength and flexibility, but we feel that if we can get every component to do what we want them to do, we can get even higher,” says Wei, who also serves as the School of Engineering’s associate dean for research and graduate education.

The new composite also exhibits resilience. Large leg bones in both adults and seniors can take a number of months to heal. The composite created in Wei’s lab does its job and then begins to degrade after a year. Surgery is not necessary for removal.

Joining Wei and Zhang in the research was Bryant Heimbach, a Ph.D. candidate and materials scientist in Wei’s lab; and Beril Tonyali, a UConn undergraduate pursuing a degree in materials science and engineering.

The team has already started testing new spin-offs of the composite, including those that include a single crystalline form of the hydroxyapatite for better strength and a variation of the coating mixture to boost its mechanical characteristics for bones bearing more weight.

The latest study was funded by a National Science Foundation grant No. 1414274 and a U.S. Department of Education GAANN Fellowship (P200A160323-17).