Apr 25 2018

Wouldn’t it be great if there were a home appliance capable of turning powdered ingredients into food at the push of a button, thereby fulfilling the individual nutrition needs of every family member? While it may seem like something straight out of science fiction, this could be made a reality in the future by a new study focused on using 3D printing to produce customized food.

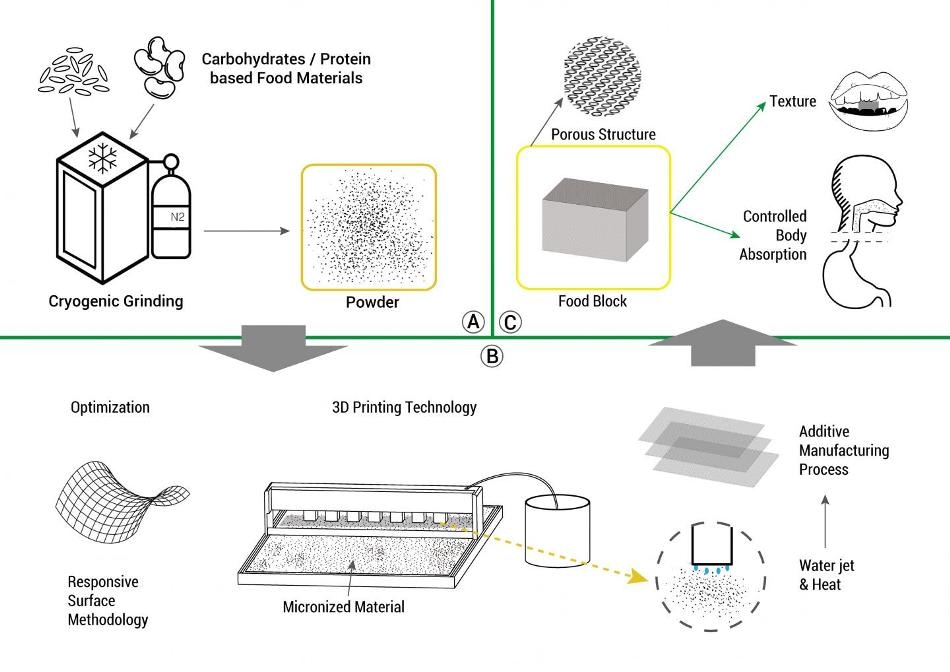

A: Food materials are pulverized under ultra-low temperature close to −100 degrees Celsius. B: Micro-sized food materials are reconstructed into a porous film-shaped material by jetting bonding an agent under optimized water content and heat conditions. The process to build film-type materials is repeated layer by layer to form a three-dimensional food block. C: The exterior of foods and internal microstructure of a food block with specific porosity is designed to give texture with controlled human body absorption while eating and ingesting. (Image credit: Jin-Kyu Rhee, Ewha Womans University)

A: Food materials are pulverized under ultra-low temperature close to −100 degrees Celsius. B: Micro-sized food materials are reconstructed into a porous film-shaped material by jetting bonding an agent under optimized water content and heat conditions. The process to build film-type materials is repeated layer by layer to form a three-dimensional food block. C: The exterior of foods and internal microstructure of a food block with specific porosity is designed to give texture with controlled human body absorption while eating and ingesting. (Image credit: Jin-Kyu Rhee, Ewha Womans University)

Jin-Kyu Rhee, associate professor at Ewha Womans University in South Korea, elaborated on his new study and the potential usage of 3D printing technology for food production at the annual meeting of the American Society for Biochemistry and Molecular Biology during the 2018 Experimental Biology meeting held from April 21 to 25, 2018, in San Diego.

We built a platform that uses 3D printing to create food microstructures that allow food texture and body absorption to be customized on a personal level. We think that one day, people could have cartridges that contain powdered versions of various ingredients that would be put together using 3D printing and cooked according to the user’s needs or preferences.

Jin-Kyu Rhee, Associate Professor

Similar to the 3D printing of other materials, 3D printing of food works in such a way that layers of raw material are deposited to produce an end product. Besides providing customized food choices, the ability to 3D print food on an industrial scale or at home could greatly minimize food wastage and the cost of transportation and storage. Moreover, it might facilitate satisfying the burgeoning food needs of an increasing global population.

For the new research, with the help of a prototype 3D printer, the team produced food with microstructures that mimicked the nanoscale texture and physical properties they observed in actual food samples. Furthermore, they showed that their platform and optimized techniques can convert protein and carbohydrate powders into food with microstructures that can be modified to manipulate the texture of the food and the way the food is absorbed by human body.

We are only in early stages, but we believe our research will move 3D food printing to the next level. We are continuing to optimize our 3D print technology to create customized food materials and products that exhibit longer storage times and enhanced functionality in terms of body absorption.

Jin-Kyu Rhee, Associate Professor

The study was presented by Jin-Kyu Rhee from 12:45 p.m. to 1:30 p.m., Tuesday, April 24, 2018, in Exhibit Halls A-D, San Diego Convention Center (poster B284 801.9).