Jan 25 2019

Scientists from Kyoto University have developed a temperature-controllable copper-based material for sieving or storing various kinds of gases. The principle based on which the material has been created could serve as a blueprint for designing nanoporous materials with a wide range of medical, energy, and environmental applications. Details of the research have been illustrated in the journal Science.

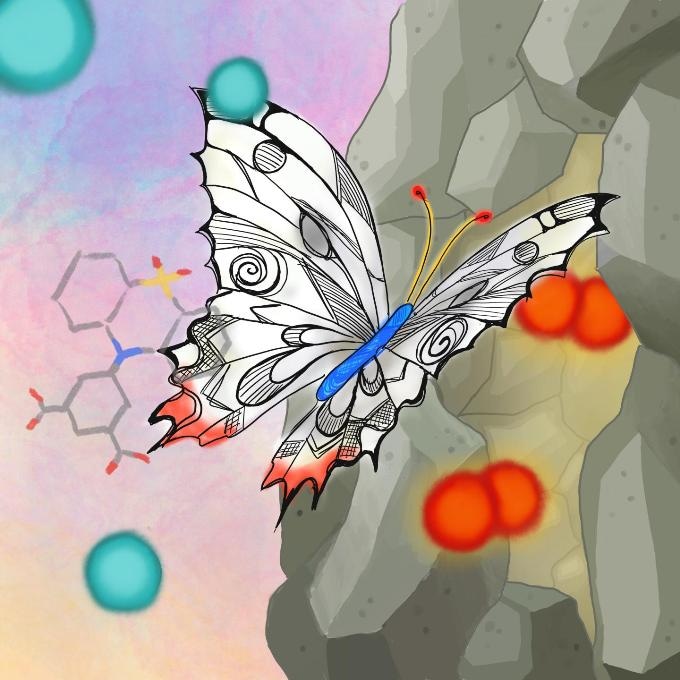

Butterfly-shaped ligands were the key to designing a material that can selectively absorb and store different gas molecules. (Image credit: Illustration by Izumi Mindy Takamiya (CC by 4.0))

Butterfly-shaped ligands were the key to designing a material that can selectively absorb and store different gas molecules. (Image credit: Illustration by Izumi Mindy Takamiya (CC by 4.0))

The porous nanomaterials that are presently used for gas separation and storage cannot be tuned: their pores are persistent and stiff. Susumu Kitagawa, Nobuhiko Hosono, and their collaborators from Kyoto University’s Institute for Integrated Cell-Material Sciences (iCeMS) intended to discover a method to dynamically alter pore sizes in this type of material.

They developed a porous coordination polymer that was formed of copper atoms connected by butterfly-shaped ligands made from phenothiazine-5,5-dioxide and isophthalic acid. The resultant material was made up of miniature nanocages, each having eight protruding channels. At extremely low temperatures, the channels linking the nanocages were so narrow that they were successfully closed. When the temperature was raised, the channels opened progressively, permitting gas molecules to travel between the cages.

The researchers learned that gas could travel or become locked within the material based on the size of the molecules of the gas and how broad the material’s channels were at a particular temperature. They also discovered that the material adsorbed gas at high temperatures and retained it in when ambient temperatures were used, successfully storing the gas.

Moreover, when the scientists applied gas mixtures to the material, they learned they could divide the gases based on the temperature applied. For instance, the material selectively adsorbed oxygen when a gas mixture of equal concentrations of argon and oxygen was applied for one hour at a temperature of −93 °C and a pressure of one bar. The material selectively adsorbed oxygen even when the concentration of argon in the mixture was considerably higher than that of the oxygen.

“The presented porous system that uses a robust framework with thermally active molecular functionality realizes temperature-regulated gas adsorption/desorption by design, in which local flexibility at the aperture plays a pivotal role,” the scientists conclude.