Jun 6 2019

Researchers from Swansea University’s SPECIFIC Innovation and Knowledge Centre have developed a new 3D printed thermoelectric device, which turns heat into electric power with an efficiency factor of more than 50% higher than the earlier best for printed materials. Furthermore, it is economical to mass produce.

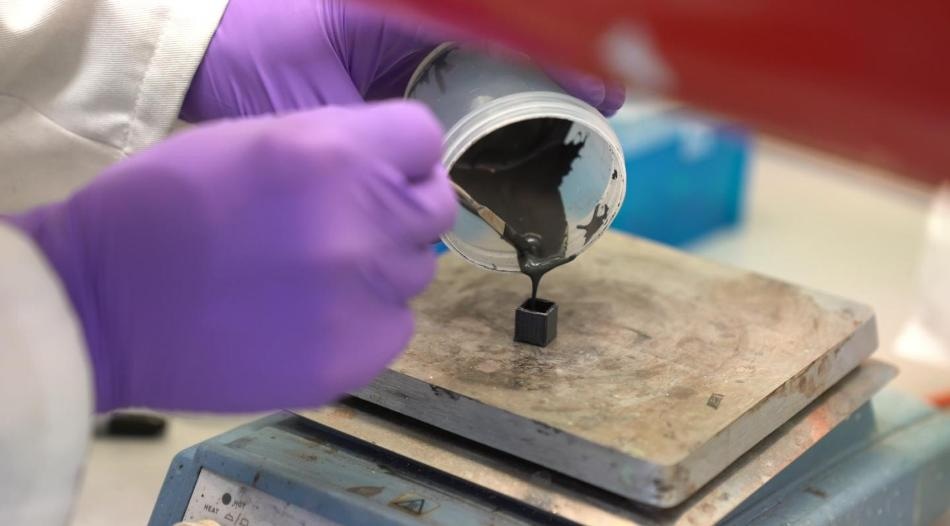

Printing Tin Selenide to turn waste heat into electrical power (Credit: SPECIFIC - Swansea University)

Printing Tin Selenide to turn waste heat into electrical power (Credit: SPECIFIC - Swansea University)

About one-sixth of all the energy consumed by industry in the UK presently ends up as waste heat, released into the air. Harnessing this to form electricity could be a giant step forward in assisting industry to cut its energy bills and decrease its carbon footprint.

Thermoelectric materials convert variances in temperature into electric power, or vice versa. They are used in power plants, fridges, and even some smartwatches that are driven by body heat.

Earlier research has revealed that a material known as tin selenide (SnSe), a compound composed of tin (Sn) and selenium (Se), contains high potential as a thermoelectric material. The issue is that the techniques used to make it needs plenty of energy and are thus not cheap.

This is where the efforts of Swansea scientists' come to play. The method they have formulated is potentially very cost-effective for industry as it allows SnSe thermoelectric generators to be manufactured rapidly and easily in large numbers.

The researchers formulated SnSe into a type of ink which they could print to examine its properties. The following step was to form a type of 3D printing method to build a small thermoelectric generator composed of the ink.

The experiments carried out by the team revealed that the material delivered record scores for efficiency in performance, which is calculated by the "Figure of Merit" (ZT).

- Swansea researchers’ element attained a ZT value (a measure of the thermoelectric generator’s efficiency) of up to 1.7

- The earlier best ZT score for a printed thermoelectric material was 1.0

- This means an efficiency rate — for converting heat into electricity — for the Swansea researchers’ element of about 9.5%, compared with 4.5% for the earlier best

The innovation could be of specific advantage to industries where high temperatures are required in the manufacturing process. Steelmaking is one such industry, which produces massive amounts of heat and requires huge electrical power. Recycling the heat into power, thus, has the potential to increase energy efficiency considerably. Tata Steel is due to support a PhD scientist on the team to investigate the technology’s industrial application.

The study team is from SPECIFIC Innovation and Knowledge Centre, a Swansea University-led project which creates technologies for decreasing carbon emissions and reveals how they can be used in buildings and industry.

Turning waste heat into electrical power can boost energy efficiency significantly, cutting bills and reducing carbon emissions. Our findings show that printed thermoelectric materials using tin selenide are a very promising way forward. The device we developed is the best-performing printed thermoelectric material recorded to date, with the efficiency factor improved by over 50% compared to the previous record. It is also cheap to produce in bulk compared with established manufacturing methods. More work is needed, but already our work shows that this technique, combining efficiency and economy, could be very attractive to energy-intensive industries.

Dr Matt Carnie, Lead Researcher, Swansea University