Jun 20 2019

Additive methods are increasingly being used by the metalworking industry since they enable fewer production faults, lower costs, and shorter production times, to name a few.

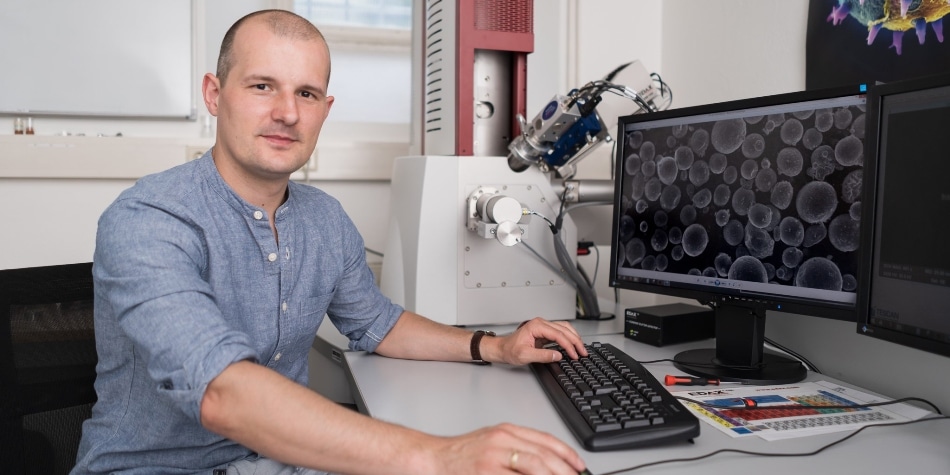

Mateusz Skalon has developed an innovative powder for 3D metal printing and is now working on its marketability (Image credit: Hoflehner—TU Graz/IMAT)

Mateusz Skalon has developed an innovative powder for 3D metal printing and is now working on its marketability (Image credit: Hoflehner—TU Graz/IMAT)

This scenario is also reflected in the market for stainless steel powder utilized in additive manufacturing. And according to estimates, this is growing by over 30% every year. Despite this fact, there is still scope for development in 3D metal printing technology. Particularly, in selective laser melting (SLM), wherein the component is constructed in layers, the scope for design is rather restricted with respect to design and development.

If the component turns out to be more complex, then more elaborate support structures will be required, for instance, to inhibit potential overhangs from sinking at the time of the printing process or other deformations of components.

More design scope and lower printing costs

In this context, Mateusz Skalon, a researcher at TU Graz’s Institute of Materials Science, Joining and Forming, has developed a novel powder for 3D metal printing. Skalon has altered the particles’ surfaces of traditional 316L stainless steel powder, so that the metal liquefied by laser beam will be able to act in a more stable manner at the time of the 3D printing process. This enables more freedom of design, because components that have low angles of inclination do not collapse at the time of printing.

This supposed NewGen SLM powder needs fewer supporting structures, which is responsible for around 20% of the overall printing expenses. In addition, savings in production are significantly reduced, as Skalon has computed: “Cost savings of up to 114 euros can be achieved per each kilo of printed metal.”

In this regard, Skalon also refers to the sustainability aspect. Towards the end of production, excess stainless steel powder can be easily recycled, which translates to more savings in terms of the materials used.

A processing system for innovative metal powder

Currently, Skalon intends to apply the research findings to businesses with the aid of TU Graz. In the context of the current Spin-Off Fellowship of the Austrian Research Promotion Agency (FFG), Skalon is scaling the modification process to bring it to market maturity.

We’ll be testing the powder on the most common laser melting systems in the next 16 months. Basing on this, we want to establish a production company in Austria directly after the Fellowship where purchased 316L stainless steel powder will be modified and sold. Target groups will include manufacturers of highly complex metal parts, manufacturing companies in the automotive, aircraft and mechanical engineering sectors as well as research institutions dealing with additive manufacturing methods.

Mateusz Skalon, Researcher, Institute of Materials Science, TU Graz

“We have already had expressions of interest from business and industry.” Skalon added. He believes that in the next few months or so, more will follow. With his spin-off, he is aiming to become an integral part of the supply chain in additive manufacturing.

A top-class team supports this young academic. Christof Sommitsch, head of TU Graz’s Institute of Materials Science, Joining and Forming, is supervising the new project, and Christoph Kovacic, the chairman of Junge Wirtschaft Steiermark, is a mentor.

Skalon receives assistance in the business development from Stefan Vorbach, the head of the Institute of General Management and Organisation at TU Graz, and also from institute staff Elisabeth Poandl and Martin Glinik.

The research area is anchored in the Field of Expertise “Advanced Materials Science,”— one of five strategic foci of TU Graz. It is funded by the Austrian Research Promotion Agency (FFG) in the “Spin-off Fellowship” funding program.