Are you currently using an optical comparator or other manual measurement methods? Have you ever considered other forms of technology that could simplify the process of using conventional measurement tools?

The Instant Measurement System is a highly versatile measurement device ideal for companies producing a low-volume, high mix of parts or components. Its user-friendly software allows all operators the ability to achieve accurate and repeatable measurement results at the push of a button.

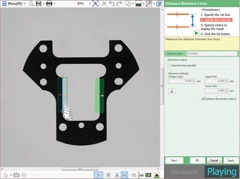

The system’s technology uses automatic edge detection to ensure zero operator subjectivity on all part or component applications. Data is even collected and recorded every time a part is measured. The system’s ability to eliminate operator error, measure parts more quickly, provide automatic data collection and be easy enough to use for all operators, makes the IM Series ideal for a diverse part or component portfolio.

FOUR REASONS TO SWITCH TO THE IM-7000 : ELIMINATE ERROR, MEASURE FASTER, BETTER REPORTING, EASE-OF-USE.

|

1 INCREDIBLY FAST PART INSPECTION

Measurements can be taken while checking the entire part with no need for positioning. Part Inspections that would take a considerable amount of time with conventional systems can be taken in just a few seconds with the IM Series. Automatic edge detection identifies part features and can be saved allowing parts with the same shape to be identified and measured at the push of a button.

|

|

2 EASY OPERATION THAT ANYONE CAN USE

All 2D measurements can be done easily using just the click of the mouse. Even complex measurements such as a radius or curved surfaces couldn't be easier. Virtual line settings are created by just clicking on the screen allowing measurements to be taken very quickly.

|

|

3 ELIMINATES HUMAN ERROR

Alignment and other human errors will not occur as edges are automatically detected in order to identify profile measurements. Dirt and burrs are also automatically detected and excluded. What's more, errors due to focusing distance are eliminated by using a lens with a large depth of field.

|

|

4 EASILY GENERATE INSPECTION REPORTS

Every time a part is measured on the system, data is automatically recorded. The unit can take the data and generate its own, customizable inspection reports.

|

By creating a system that can help to eliminate operator error, measure parts more quickly, provide automatic data collection and be easy enough to use for all operators, KEYENCE believes the IM Series is ideal for companies with a diverse part or component portfolio. If you are looking to invest in new measurement technology, we’d appreciate you considering the Instant Measurement Series. The systems versatility makes it ideal for all industries and all process applications.