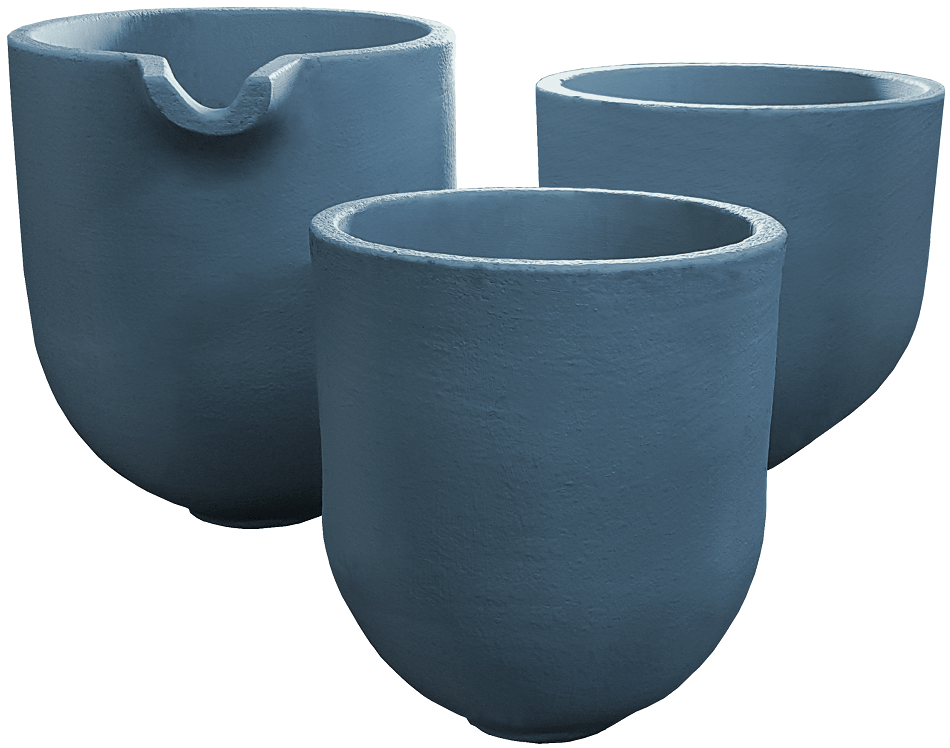

A technological advance in materials science is supporting customers to increase productivity, by offering more than a 50% increase in the lifespan of crucibles used in the aluminium casting process*. VAluStar™ crucibles are the latest and most advanced range of crucibles developed by Morgan Advanced Materials.

Conceived by Morgan’s Molten Metal Systems business, the crucibles are highly resistant to oxidation at low temperatures thanks to Morgan’s proprietary glazes. They are particularly suited to holding aluminium and aluminium alloys in electric resistance furnaces.

VAluStar™ crucibles are high density, clay-bonded, iso-statically pressed crucibles that contain a high graphite and silicon carbide content.

We are delighted to launch our VAluStar™ crucibles. We are confident they will add huge value to the aluminium casting industry by reducing downtime and maintenance, therefore increasing productivity. Our new family of crucibles has been developed to resist oxidation, which is a common challenge for operators in modern foundries and cast houses. We’ve rigorously tested them against other crucibles in similar operating conditions, and VAluStar™ has shown that it has a significantly longer lifetime than all other iso-statically pressed crucibles in low temperature applications.

Robin White, General Manager, Molten Metal Systems

To demonstrate the difference, Morgan tested the VAluStar™ in a 24-hour aluminium melting and holding application, against a conventional iso-statically pressed crucible. The latter needed to be replaced after eight months due to a reduction in thermal conductivity and when top brim cracks occurred due to oxidation.

Meanwhile, the BNS 200 VAluStar™ crucible’s lifetime was 14 months, exceeding the conventional crucible’s service life by 75% in similar conditions. As well as the extended life of the crucible, thermal productivity was improved by 24%.

Crucially, both crucibles were split in half for analysis. While the conventional crucible showed brim oxidation and oxidation nests, the VAluStar™ crucible only showed a slight brim oxidation, which was caused by the insulation fibre.

For more about Morgan’s Molten Metal Systems business and the VAluStar™ crucible technology, please visit http://www.morganmms.com/en-gb/products/crucibles/noltina/valustar/

*when compared to existing Morgan Advanced Materials crucibles.