Jan 23 2020

According to old mythology, horsemen were instructed by Genghis Khan to wear vests made of silk under their body armor to further protect themselves against a series of arrows during combat.

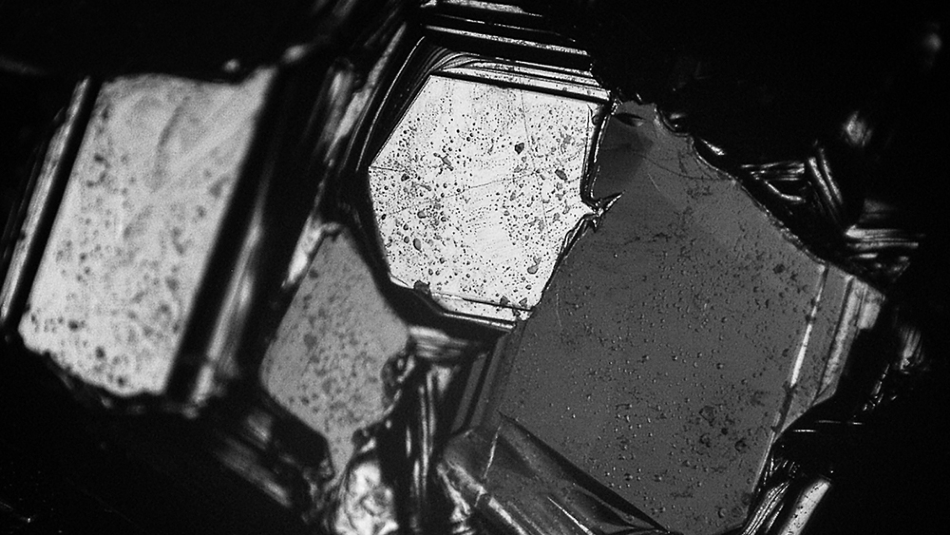

A close-up view of boron carbide crystals. Image Credit: Dharmesh Patel/Texas A&M Engineering.

A close-up view of boron carbide crystals. Image Credit: Dharmesh Patel/Texas A&M Engineering.

Since that period, body armor has evolved considerably. Silk was replaced by ultra-hard materials that function like impassable walls against a majority of ammunition. But even this kind of body armor can probably fail, especially when it is bombarded by fast-moving objects such as high-speed ammunition.

At Texas A&M University, scientists have come up with a novel method that can eliminate the drawbacks found in contemporary armor.

Boron carbide is a material that is often used for constructing body armor. When the researchers added a small amount of silicon to this material, they found that bullet-resistant gear can be made considerably more resistant to fast-moving impacts.

For the past 12 years, researchers have been looking for ways to reduce the damage caused by the impact of high-speed bullets on armor made with boron carbide. Our work finally addresses this unmet need and is a step forward in designing superior body armor that will safeguard against even more powerful firearms during combat.

Dr Kelvin Xie, Assistant Professor, Department of Materials Science and Engineering, Texas A&M University

The research was published in the October issue of the Science Advances journal.

Termed “black diamond,” boron carbide is a synthetic material and takes the second place after another manmade material known as cubic boron nitride, in terms of hardness.

But unlike cubic boron nitride, boron carbide can be produced more easily and on a commercial scale. Boron carbide is also lighter and harder when compared to other armor materials such as silicon carbide, and therefore, it is a perfect choice for protective gear, specifically ballistic vests.

However, while boron carbide has many preferred qualities, it is likely to get damaged quickly upon high-speed impact, which is believed to be a major drawback.

Boron carbide is really good at stopping bullets traveling below 900 meters per second, and so it can block bullets from most handguns quite effectively. But above this critical speed, boron carbide suddenly loses its ballistic performance and is not as effective.

Dr Kelvin Xie, Assistant Professor, Department of Materials Science and Engineering, Texas A&M University

Researchers are aware that boron carbide undergoes phase transformations when subjected to high-velocity impacts. Phase transformation is a phenomenon in which a material alters its internal structure so that it exists in two or more physical states, for example, solid and liquid states, simultaneously.

Therefore, because of the impact of a bullet, boron carbide transforms from a crystalline state, in which atoms are methodically assembled, to a glass-like state, in which atoms are randomly organized. A glass-like state such as this weakens the integrity of the material at the place of contact between boron carbide and the bullet.

“When boron carbide undergoes phase transformation, the glassy phase creates a highway for cracks to propagate,” added Xie. “So, any local damage caused by the impact of a bullet easily travels throughout the material and causes progressively more damage.”

According to an earlier study that involved computer simulations, boron carbide can be made less fragile by introducing a tiny amount of another element, like silicon. Along with his team, Xie explored whether phase transformation can be reduced by adding a small amount of silicon.

To replicate the initial impact of a high-velocity bullet, the scientists used a diamond tip to make well-regulated dents on samples of boron carbide. The width of this diamond tip is smaller than that of a single strand of human hair. Subsequently, the researchers observed the tiny damage caused by the impacts under a high-powered electron microscope.

Xie and his colleagues discovered that even when negligible amounts of silicon were added, the degree of phase transformation reduced as much as 30%, perceptibly decreasing the damage caused by the indentation.

While silicon is suitable to improve the properties of boron carbide, additional experiments have to be performed to find out whether other elements, such as aluminum and lithium, can also enhance the performance of boron carbide, stated Xie.

According to Xie, these more robust cousins of pure boron carbide could also be used in other nonmilitary applications in the days to come. Nuclear shields are one such application.

Adding a small amount of silicon to boron carbide alters the spacing that exists between atoms, and the vacant spaces produced may serve as excellent sites to absorb dangerous radiation released by nuclear reactors, he further added.

Just as in cooking where a small sprinkle of spices can greatly boost flavor, by using a small amount of silicon we can dramatically improve the properties of boron carbide and consequently find novel applications for these ultrahard materials.

Dr Kelvin Xie, Assistant Professor, Department of Materials Science and Engineering, Texas A&M University

The study also involved Dr Sisi Xiang, Yvonne Dieudonne, Dr George M. Pharr, and Digvijay Yadav, all from the Department of Materials Science and Engineering at Texas A&M; and Dr Kevin J. Hemker and Dr Luoning Ma from the Department of Mechanical Engineering at Johns Hopkins.

Other contributors were Bruce Yang, Dr Chawon Hwang, and Dr Richard A. Haber from the Department of Materials Science and Engineering at Rutgers University; Dr Jing Lu from NanoMEGAS USA; and Dr Jerry C. LaSalvia from the U.S. Army Research Laboratory.

The Defense Advanced Research Projects Agency partly funded the study. Xie’s start-up grant from the Texas A&M Engineering Experiment Station (TEES) extended additional support.

Texas A&M engineers develop recipe to dramatically strengthen body armor

Boron carbide is harder and lighter than other armor materials making it an ideal choice for protective gear, particularly ballistic vests. Video Credit: Dharmesh Patel/Texas A&M Engineering.