Sep 28 2020

Fuel cells are different from secondary batteries that need to be recharged and are a kind of environmentally-friendly power generation systems that generate electricity directly from electrochemical reactions using oxygen as oxidant and hydrogen as fuel.

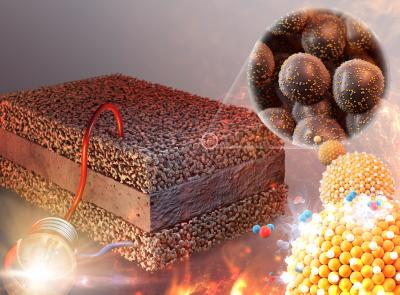

Conceptual diagram of a single-atom catalyst developed by KIST researchers. Image Credit: Korea Institute of Science and Technology (KIST).

Conceptual diagram of a single-atom catalyst developed by KIST researchers. Image Credit: Korea Institute of Science and Technology (KIST).

There are numerous kinds of fuel cells that vary in electrolyte materials and operating temperatures. Amongst them, the solid oxide fuel cell (SOFC), which makes use of a ceramic electrolyte, is attracting a great deal of attention.

Since the SOFC works at elevated temperatures around 700 °C, it provides the highest efficiency among numerous fuel cells, and it can even be used for generating hydrogen through steam decomposition.

To commercialize the technology, the performance of the fuel cells had to be further enhanced, and innovative high-temperature catalyst materials are highly expected.

Such exceptional performance in fuel cell electrode reactions has been demonstrated by platinum (Pt)-based catalysts. Specifically, single-atom Pt catalysts are intensively studied because of their special functionality.

But at elevated temperatures, the Pt atoms are unstable and tend to agglomerate easily. Thus, Pt single-atom catalysts have been utilized only in low-temperature fuel cells, such as polymer-electrolyte membrane fuel cells, which is utilized in hydrogen-electric vehicles.

Under such conditions, a domestic research group has designed a catalyst that needs just a small amount of platinum to considerably improve the performance and can work stably at high temperatures.

The Korea Institute of Science and Technology (KIST) declared that Dr. Kyung-Joong Yoon and Researcher Ji-Su Shin from the Center for Energy Materials Research, along with Professor Yun -Jung Lee from Hanyang University (Hanyang University, President Woo-Seung Kim), designed a single-atom Pt catalyst that can be utilized for SOFCs.

In their study, the entire platinum atoms were uniformly distributed and work separately without agglomeration even at elevated temperatures. This method has been experimentally demonstrated to boost the electrode reaction rate over 10 times.

Moreover, it can function for over 500 hours even at increased temperatures of up to 700 °C and enhances the generation of electric power generation and the performance of hydrogen production by 3 to 4 times. It is anticipated to expedite the commercialization of solid oxide fuel cells (SOFCs)—the next-generation environmentally-friendly fuel cells.

The single-atom catalyst mutually designed by the KIST-Hanyang University research group was created by integrating cerium (Ce) oxide nanoparticles and platinum atoms.

Every platinum atom has been separately dispersed on the surface of cerium oxide nanoparticles, and the robust bond retains the dispersed state of the atoms for a longer period even at elevated temperatures, enabling all platinum atoms to take part in the reaction.

This consequently makes it feasible to significantly enhance the rate of the electrode reaction while reducing the amount of platinum utilized.

For the fabrication process, a solution containing cerium and platinum ions is administered into the SOFC’s electrode, and the catalysts are produced while the fuel cell is working at a high temperature.

Since special equipment is not needed to inject into the electrode, it is anticipated that the newly designed catalyst can be readily used on present-day fuel cell fabrication processes.

The catalyst developed in this study can be applied to a wide variety of solid oxide fuel cells and high-temperature electrochemical devices using an easy and simple low-cost process, so it is expected to accelerate the development of next-generation eco-friendly power generation and energy storage devices.

Dr Kyung-Joong Yoon, Korea Institute of Science and Technology

Yoon added, “Based on the fact that the single-atom catalyst can operate stably even at 700 degrees Celsius or higher, its application fields will be greatly expanded, including high-temperature thermochemical reactions and high-temperature electrochemical reactions.”

The research was performed with a grant from the Ministry of Science and ICT (MSIT), as part of the Institutional R&D Program of KIST and the Korea Research Foundation’s Program on Development of Technology in reaction to Climate Change. The article was published in the new edition of the Energy & Environmental Science journal.

Journal Reference

Shin, J., et al. (2020) Highly active and thermally stable single-atom catalysts for high-temperature electrochemical devices. Energy & Environmental Science. doi.org/10.1039/D0EE01680B.