Nov 5 2020

Researchers from the University of Nottingham have solved the mystery of how to utilize inks to 3D-print advanced electronic devices that have useful characteristics, for example, the potential to change light into electricity.

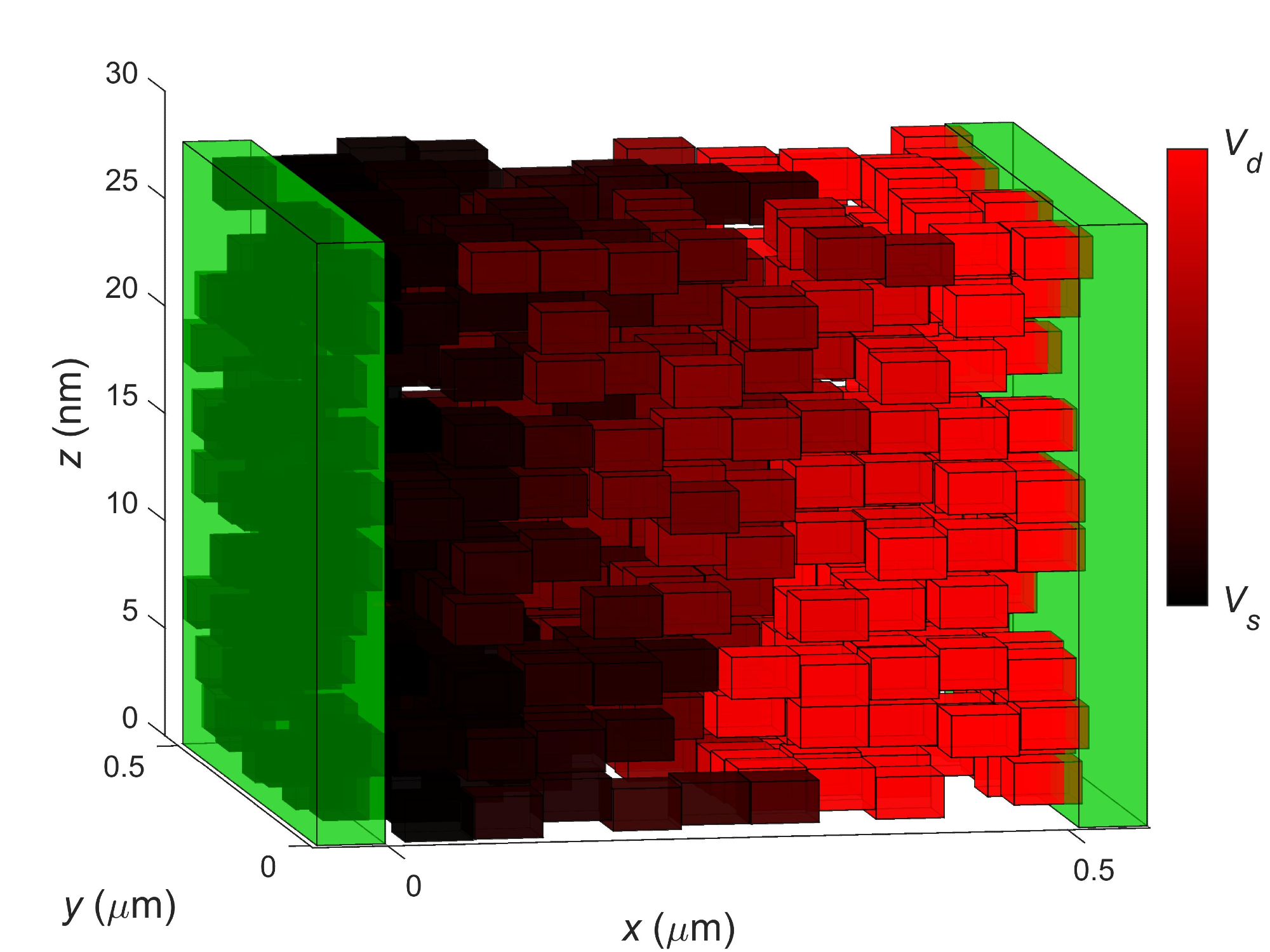

A representative arrangement of graphene flakes in ink-jet printed graphene between two contacts (green). The color gradient corresponds to the variation of flake potentials. Image Credit: University of Nottingham.

A representative arrangement of graphene flakes in ink-jet printed graphene between two contacts (green). The color gradient corresponds to the variation of flake potentials. Image Credit: University of Nottingham.

The research work demonstrates that jet inks, consisting of minute flakes of two-dimensional (2D) materials, like graphene, could accumulate and collectively mesh the varying layers of these complex, custom-made structures.

With the help of quantum mechanical modeling, the team also demonstrated how electrons travel via the 2D material layers, to gain a deeper understanding of means to modify the innovative devices in the days to come.

By linking together fundamental concepts in quantum physics with state-of-the art-engineering, we have shown how complex devices for controlling electricity and light can be made by printing layers of material that are just a few atoms thick but centimetres across.

Mark Fromhold, Study Co-Author, Professor, and Head of the School of Physics and Astronomy, University of Nottingham

Professor Fromhold continued, “According to the laws of quantum mechanics, in which the electrons act as waves rather than particles, we found electrons in 2D materials travel along complex trajectories between multiple flakes. It appears as if the electrons hop from one flake to another like a frog hopping between overlapping lily pads on the surface of a pond.”

The study titled, “Inter‐Flake Quantum Transport of Electrons and Holes in Inkjet‐Printed Graphene Devices,” has been published in Advanced Functional Materials—a peer-reviewed journal.

Graphene is generally described as a “super material” and was initially produced in 2004. This material has several special properties, for example, it is highly flexible, stronger than steel, and is the best conductor of electricity to be ever developed.

Graphene and other similar 2D materials are often produced by sequentially exfoliating one layer of carbon atoms, which are organized in a flat sheet. These carbon atoms are then used for making customized structures.

But it has been difficult to create layers and integrate them to produce intricate, sandwich-like materials, and the process often involved meticulous deposition of the layers by hand and in a sequential manner.

Ever since the discovery of graphene, there has been a phenomenal growth in the number of patents that involved graphene. But to fully leverage the potential of this material, scalable manufacturing methods should be designed

The latest article demonstrates that additive manufacturing—often called 3D printing—using inks, wherein tiny graphene flakes (measuring a few billionths of a meter across) are suspended, offers a potential solution.

By integrating sophisticated manufacturing methods to develop devices along with advanced techniques of quantifying their characteristics and quantum wave modeling, the researchers found out precisely how single-layer graphene can be effectively replaced by inkjet‐printed graphene as a contact material for 2D metal semiconductors.

While 2D layers and devices have been 3D printed before, this is the first time anyone has identified how electrons move through them and demonstrated potential uses for the combined, printed layers. Our results could lead to diverse applications for inkjet‐printed graphene‐polymer composites and a range of other 2D materials.

Dr Lyudmila Turyanska, Study Co-Author, Centre for Additive Manufacturing, University of Nottingham

Dr Turyanska continued, “The findings could be employed to make a new generation of functional optoelectronic devices; for example, large and efficient solar cells; wearable, flexible electronics that are powered by sunlight or the motion of the wearer; perhaps even printed computers.”

The research was performed by engineers from the Centre for Additive Manufacturing and by physicists from the School of Physics and Astronomy who share a common interest in quantum technologies. It was carried out under the £5.85m EPSRC-funded Programme Grant, Enabling Next Generation Additive Manufacturing.

The team employed a broad range of characterization methods, such as thermal gravity analysis, micro‐Raman spectroscopy or laser scanning, electrical measurements, and an innovative 3D orbiSIMS instrument, to offer an in-depth functional and structural understanding of inkjet‐printed graphene polymers, and the impacts of annealing or heat treating on performance.

The subsequent steps for the study are to improve the control of depositing the graphene flakes by utilizing polymers to control the way they organize and align and try out different kinds of inks with an array of flake sizes.

The team is also hoping to create more advanced computer simulations of the materials and the way they operate together, thus creating ways for large-scale production of devices modeled by them.

Journal Reference:

Wang, F., et al. (2020) Inter‐Flake Quantum Transport of Electrons and Holes in Inkjet‐Printed Graphene Devices. Advanced Functional Materials. doi.org/10.1002/adfm.202007478.