Because of its transparency, quality, biocompatibility, and structural qualities equivalent to those of traditional materials, polylactic acid or PLA is one of the most promising biopolymer possibilities.

PLA is a non-toxic, biodegradable bio-based polymer with great mechanical resilience and plasticity that is generated from starch and/or molasses. EFSA has approved it for use in product, food and beverage packaging.

PLA is made largely of lactic acid, which may be made from renewable sources such as potatoes, grains, and maize starch. PLA is more environmentally benign than oil polymers, which increase fuel energy consumption and greenhouse gas pollution. Furthermore, the gas-permeable characteristics, as well as its transparency to UV radiation, limit its use in various applications, particularly in food packaging.

To predict and increase the shelf life of foods, such limitations must be overcome.

Oxidation reactions, that affect the quality of food and create hazardous chemicals, are caused by both UV light and oxygen.

When exposed to ultraviolet radiation, both artificial and natural, the PLA structure quickly degrades and weakens. This causes the polymer to shift color and allow more UV light to pass through. As a result, improving PLA's barrier and UV protection qualities becomes critical.

Some researchers have used Magnesium Oxide or Zinc Oxide, but recent findings employ tungsten oxide (WOx) with high photoabsorption capabilities and a safety analysis to be used in contact with food that have been issued by the European Food Safety Authority (EFSA).

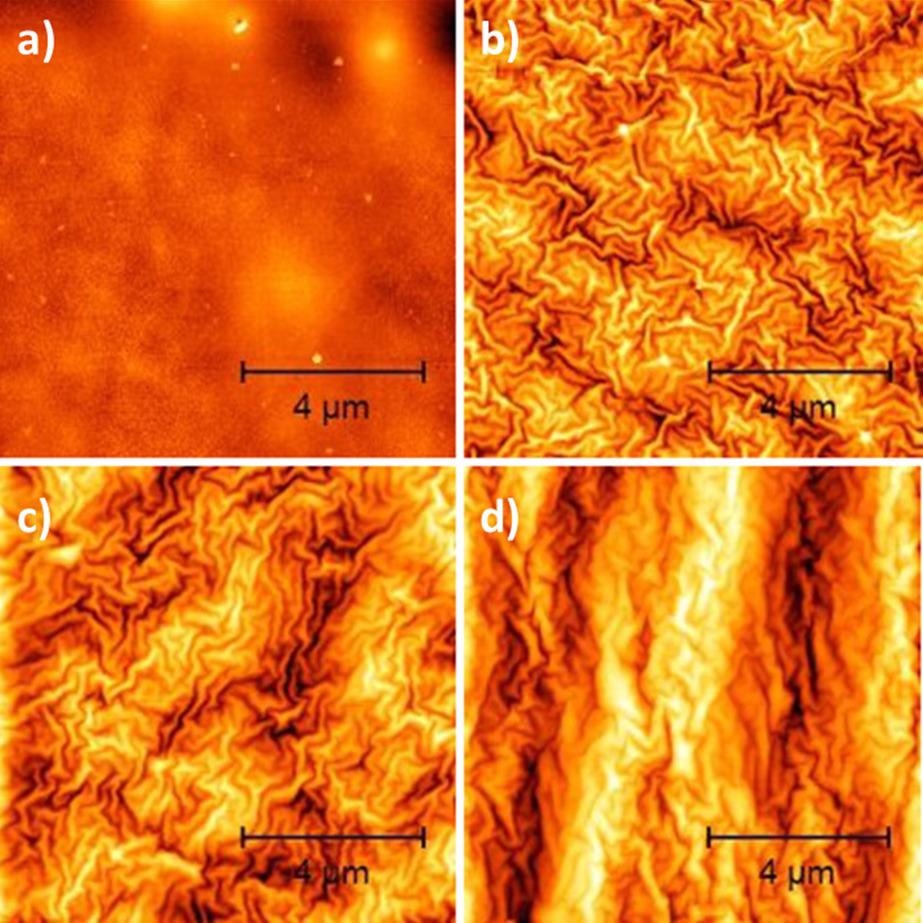

AFM images of (a) pristine PLA and (b) PLA/25 nm WOx, (c) PLA/50 nm WOx and (d) PLA/100 nm WOx.

When WOx was employed as a reheating agent for polyethylene terephthalate (PET), safety tests were done. Additional immigration experiments must be done for various system functions or to be used in alternative polymers, according to the specification. Ultimately, WOx can be utilized as an effective antibacterial to provide active food containers that help avoid foodborne illnesses.

The research employed WOx layers on pure PLA and WOx thin layers on PLA covered with various WOx thicknesses. 30 percent oxygen was maxed to the WOx.

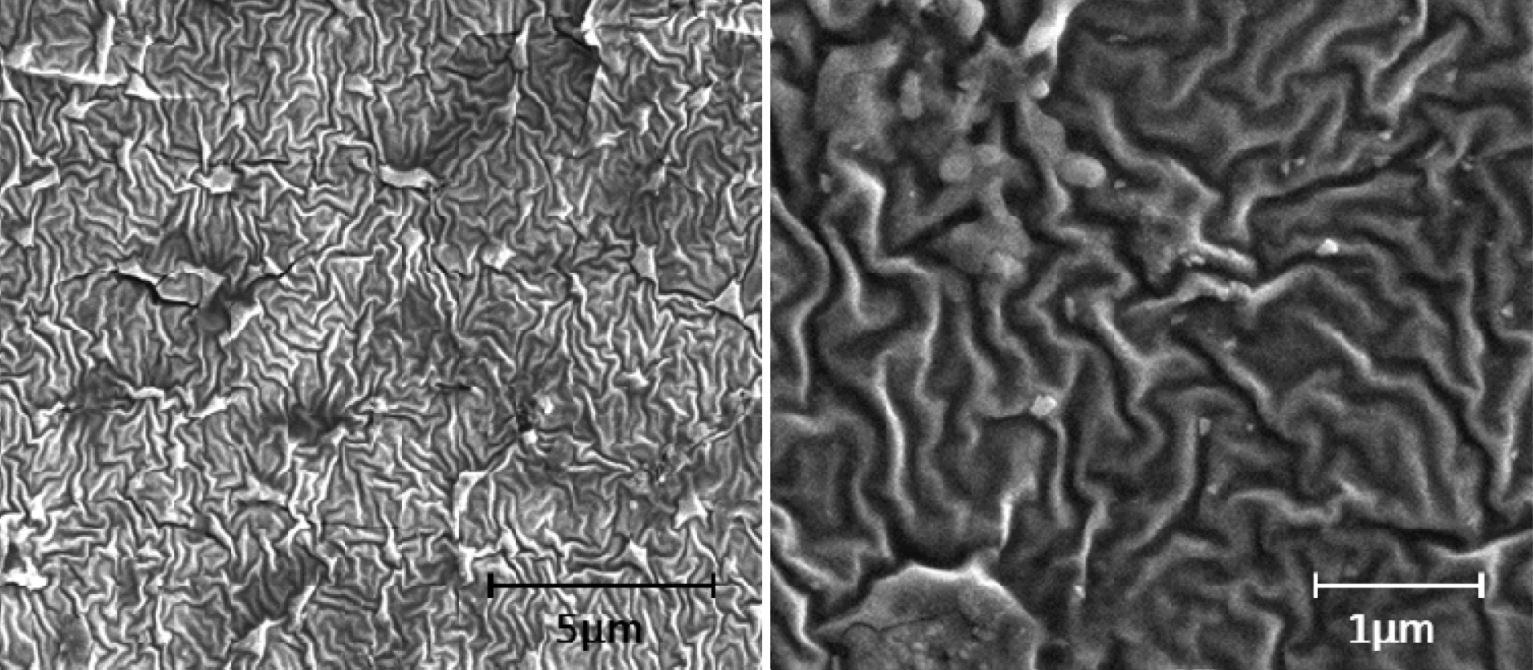

SEM image of PLA/25 nm WOx at different magnifications.

Permeability to oxygen was tested using a high-vacuum prototype model, according to the findings. In manometers operations, the device uses a mass spectrometer to determine gas permeability.

The findings are reliable for a variety of parameters, including the permeability of packing materials, covering many orders of magnitude. An additional benefit is that observations may be traced in situ while sacrificing the benefits of a state-of-the-art advertising instrument; rather, using mass spectrometry, the gas transfer rate can be measured directly, quickly, and purposefully through any tracer gas.

Thermally produced residual stress has given the coating a ripple-like shape.

The accumulating thermal stress is caused by gas particles infringing on the growing layer as well as the huge disparity in thermal expansion coefficients between WOx and PLA.

When opposed to clean PLA, the transmission of the PLA/WOx specimens reduces dramatically across the UV-visible range of wavelength. This demonstrates that sub-stoichiometric WOx or tungsten oxides have adequate photoabsorption characteristics.

The presence of pristine PLA that are fully transparent has been documented in the literature.

The absorption of light by WOx improves on thickness up to 50 nm. Inside this thickness range investigated, higher film thicknesses would not result further in substantial light absorption. In comparison to pristine PLA, the WOx samples diminish light transmittance by around 95% in the UV-B spectrum, 70% in the UV-A spectrum, and 50% in the visible range.

WOx layers, in addition to dramatically lowering UV light transmission, also restrict transmittance in the visible area, retaining polymer transparency.

These was tested for antibacterial properties against E.coli ATCC 8739.

In contrast to pure PLA, the Escherichia coli decline after 24 hours in interaction with the WOx-coated PLA. These early findings support WOx coatings' good antibacterial efficacy versus Escherichia coli.

There seems to be, however, a minimal thickness below which bacteria viability is not compromised. The smaller coating's lower antibacterial activity might be attributable to a lack of effective surface area in comparison to the amount of the E. coli inoculum. In addition, the overall roughness rises, which is a significant element in improving the bactericidal activity of a substantial amount of WOx.

PLA films layered with tungsten oxide thin films increased qualities including oxygen barrier, antibacterial activity, and UV light protection. The electrodeposition process allowed for the creation of sub-stoichiometric WOx coatings of excellent quality and uniformity.

Coatings thicknesses of 50 nm and 100 nm offered the highest overall performance as a result of applications. In comparison to pure PLA, both have a light transmittance loss of roughly 95 percent in the UV-B area, 70 percent in the UV-A spectrum, and 50 percent in the visible range.

Journal Reference:

Pedroni, Matteo, Espedito Vassallo, Marco Aloisio, Milena Brasca, Hao Chen, Giuseppe Firpo, Francesco Ghezzi, Stefano Morandi, Silvia M. Pietralunga, Tiziana Silvetti, and Tersilla Virgili. 2021. "Plasma Sputtered Tungsten Oxide Thin Film on Poly(lactic acid) for Food Packaging Applications" Coatings 11, no. 11: 1281. https://doi.org/10.3390/coatings11111281, https://www.mdpi.com/2079-6412/11/11/1281

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.