The researchers, Professor Alina Karabchevsky and Ph.D. student Anastasia Novikova, applied a mechanical dispersion method for extracting graphene from natural mineral shungite rock. They discovered that mineral shungite demonstrates good promise for generating industrial-scale volumes of graphene and graphene-like matter.

Shungite and its Industrial Application

Shungite is a known mineraloid primarily found in Russia near the Lake Onega area of Karelia, near Shunga village – from where it takes its name. Shunga deposits also occur in other areas of Russia, namely Chelyabinsk and Vozhmozero, as well as being found in Austria, India, the Democratic Republic of Congo, and Kazakhstan.

Shungites can vary in their carbon content, going from one end of the spectrum to the other from low- (5%) to high-carbon (80%) content; percent by weight of carbon. Thus, depending on the carbon content, shungite can have varying application potential. Some types may be used for their catalytic properties, whereas others have bactericidal properties.

The structural properties of shungite rocks are responsible for their application in oxidation-reduction processes. Moreover, shungite can be used in blast furnace production of foundry (high-silicon) cast iron and in ferroalloy production.

As a result of its physical and mechanical properties, bulk density, good strength, and abrasion, shungite can be used practically as a filtering material as it also has a sorption capacity for a variety of organic substances. It also demonstrates the ability to eliminate radical particles that can contaminate water supplies.

“Shungite shows the ability to disinfect and purify water from bacteria, spores, simple microorganisms, and blue-green algae. Due to its high catalytic and reducing properties, shungite is often used for wastewater treatment as adsorbents,” says Karabchevsky.

Additionally, since it was first discovered in the mid-18th century, shungite has been used as a pigment for paint and is usually sold under the names carbon black, or shungite natural black.

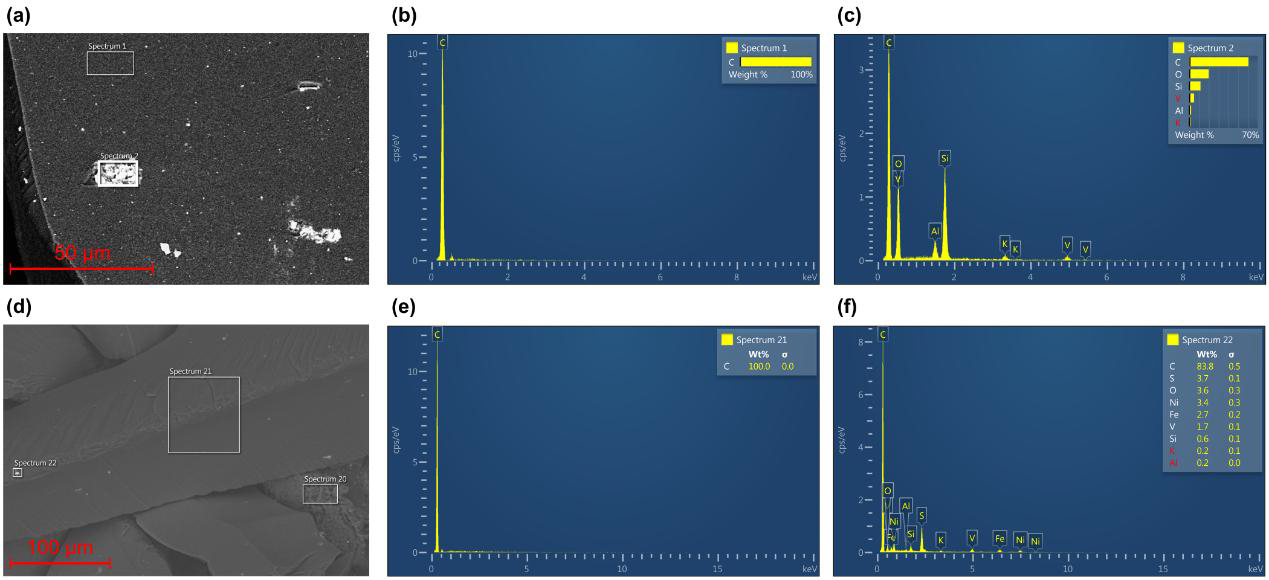

SEM images and EDS images of shungite particles: (a) studied region 1, (b) chemical composition region 1, (c) chemical composition of region 2, (d) studied region 2, (e) chemical composition region 21 and (f) chemical composition of region 22. Image Credit: arXivLabs

Graphene Extraction

In order to prepare the rock for graphene extraction, the pair checked the samples for heavy metal impurities and porosity using a scanning electron microscope (SEM). They also applied other laboratory methods to check the general structural make-up and presence of other minerals in the shungite.

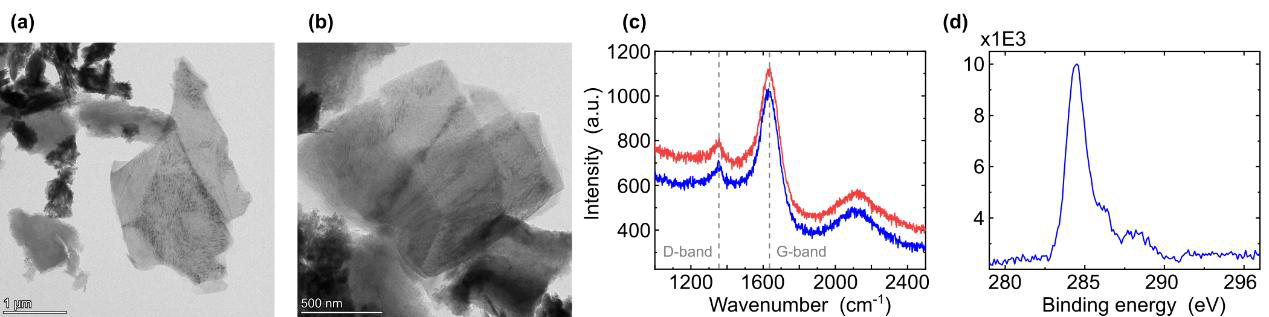

Once sample analysis and preparation were complete, Karabchevsky and Novikova were able to extract graphene from shungite rock after mechanically processing a sample sourced from Karelia, using a digital ultrasonic cleaner.

Karabchevsky and Novikova found that since large volumes of samples can be processed using this method, there is no risk of secondary contamination, and subsequent sample processing methods are not necessary.

Since the extraordinary characteristics of graphene are already widely known throughout the wider scientific research community, numerous production and synthesis methods have already been developed. However, many of these methods are either multi-step processes or require the use of chemicals and strong oxidizing and reducing agents.

TEM images of dispergated shungite sample at (a) magnification of X13500 and (b) magnification of X35000. (c) Raman spectrum of processed shungite and (d) XPS spectra of lines of carbon in the shungite spectra. Image Credit: arXivLabs

In Conclusion

As much as graphene and other carbon films demonstrate great application potential and have had relative R&D success, processes for working with these materials are still in development. Part of the challenge is making graphene extraction cost-effective, which means finding the right dispersion technique is key.

As previously stated, such dispersion or synthesis methods are laborious and not very environmentally friendly, and the intensity of these techniques can also lead to defects in any graphene produced, therefore diminishing the exceptional qualities expected of graphene.

The application of ultrasonic cleaners for the synthesis of graphene takes away the risks and costs associated with multi-step and chemical methods. Applying this method to natural mineral shungite paves the way for a new and environmentally sound way of producing graphene.

“It does not require additional costs and does not imply secondary contamination of the environment and this creates new prospects for the use of Shungite, stated Karabchevsky.

As such, Karabchevsky and Novikova have shown how green fabrication of graphene could also provide new opportunities across a wide range of industries: from electronics (electrodes), optics to biotechnology (biosensors, drug delivery, biomedicine), energy (supercapacitors, solar cells, energy harvesting) and ecology (sorbents for wastewater, air purification).

References:

Anastasia Novikova and Alina Karabchevsky, ‘Green-extraction of carbon thin films from natural mineral Shungite’ arXivLabs. https://arxiv.org/abs/2110.12790 accessed October 2021]

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.