Self-morphing materials hold great potential for the future of materials science. One field that could impact human society greatly with these materials is architecture. A recent study published in the journal Advanced Science has demonstrated new fabrication techniques for turning conventional construction materials into promising smart, self-morphing materials.

Study: Shaping by Internal Material Frustration: Shifting to Architectural Style. Image Credit: Narin Nonthamand/Shutterstock.com

Taking Inspiration from the Shape-Changing Abilities of Organic Structures

Creating self-morphing materials for industrial applications can take inspiration from nature. Many shape-morphing materials where matter is changed into complex smooth surfaces are abundant in nature, but the phenomenon has only recently been studied as a model for materials design.

Studies into natural shape-changing materials and structures have yielded information on morphological changes, where flat sheets form complex three-dimensional structures. Natural structures achieve this in a quantitatively controlled manner.

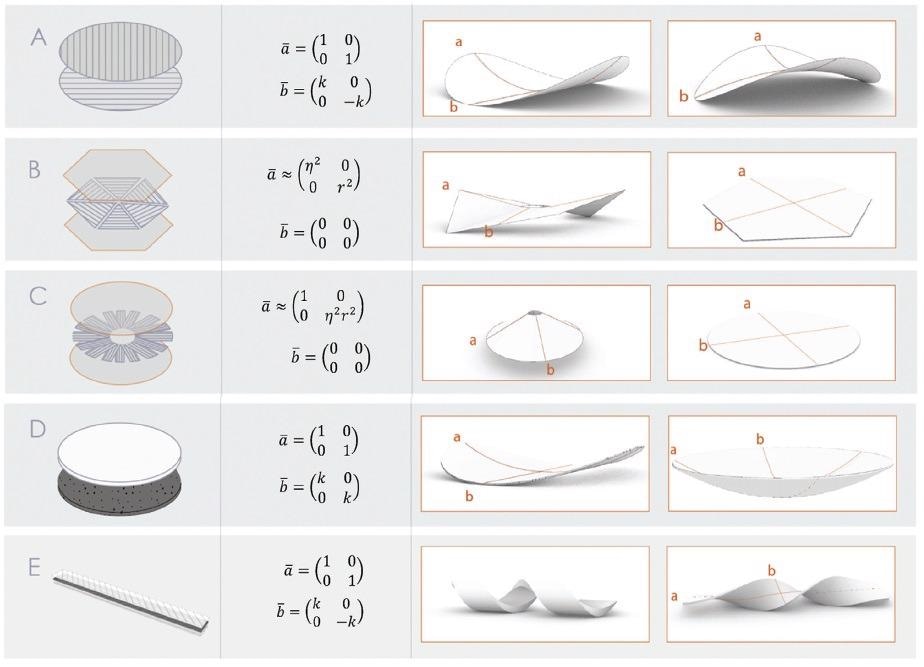

A schematic catalog of possible geometries in frustrated ceramics and frustrated composites, showing the material construction (left column) the reference metrics and reference curvature (middle column), and resulting configurations (right column), within the different regimes: stretchingdominated (left) and bending-dominated regime (right). (see physical examples in Figure S3 in the Supporting Information). Frustrated composites A) incompatible shells made by two layers of unidirectional fibers. B,C) Non-Euclidean Plates, made by one layer of patterned unidirectional fibers sandwiched in two isotropic layers of epoxy. Frustrated ceramics: D) Incompatible shells made by two joint layers of high-shrinkage ceramic (white) and low shrinkage ceramic (dark). E) Triple-layered construction, low shrinkage ceramic sandwiched between two layers of higher shrinkage ceramic with opposing grooves, resulting in twisted ribbons. Image Credit: Blonder, A & Sharon, E, Advanced Materials

Studies performed in this area have scientific importance for their application in biological systems and nanotechnology, but beyond these fields, there is scope for their use in industry. Due to the need to manufacture complex curved surfaces with minimal energy use and effort, shape-changing materials have the potential for industrial design and architecture. Currently, these applications are limited, and the materials mainly explored have been small-scale bilayer structures that undergo uniaxial bending.

Materials that can self-morph into complex three-dimensional shapes and curvatures by geometrical frustration for architectural applications need to be explored further if the technology is to be fully realized for this purpose.

The Research

The research focused on imbuing fiber composites and clay—two traditional construction materials—with shape-morphing properties, which demonstrates the possibility of creating smart, self-morphing materials from commonly used materials in the construction industry. The quantitative connection between the small-scale structure of the material and the global three-dimensional surface were verified by controlled experiments.

The team demonstrated and developed the theory of incompatible sheets in the lab using so-called “model” materials. These materials include nematic elastomers, gels, and elastomers. It was demonstrated that the properties of these materials did not meet the specific requirements of the architecture industry such as robustness, strength, stiffness, durability, cost, and standard dimensions. New materials must therefore be developed to meet these needs.

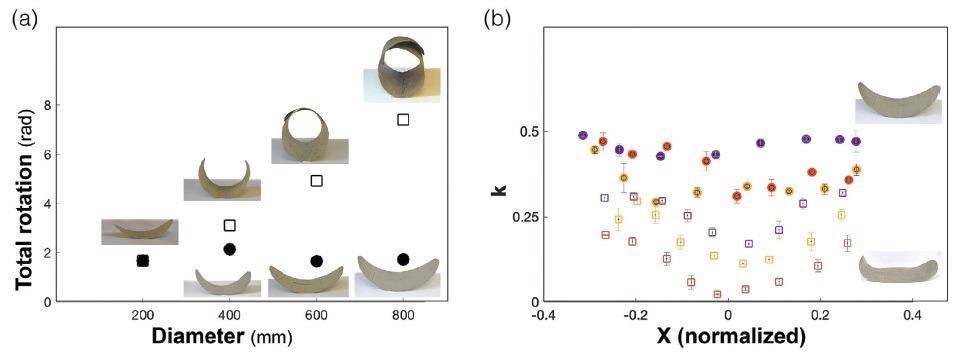

Scaling up and the effect of gravity in FC samples. a) Total surface rotation versus disc diameter measured for free-hanging discs (negligible gravity effect). Discs with constant thickness of 2 layers (open squares) demonstrate linear increase of total surface rotation, as visible in inset photos. Discs with proportionally varying thickness (solid circles), demonstrate constant surface rotation, i.e., preservation of shape upon scaling. b) The local curvature measured along the principal direction of horizontally placed discs (non-negligible gravity effect), as function of the normalized distance from the disc’s center. While in discs with proportionally varying thickness (solid circles) the curvature is approximately constant, discs of constant thickness of two layers (open squares) flatten in their center, by their own weight. Discs diameters: 800 mm red; 600 mm yellow; 400 mm purple. Inset: images of 800 mm scaled (top) and unscaled (bottom) discs. Image Credit: Blonder, A & Sharon, E, Advanced Materials

Ceramic and fiber composite materials were selected for the research due to their conventional use in the architecture industry as thin sheets for cladding and other purposes. Another property that made them attractive targets for self-morphing materials was the change in volume they undergo during fabrication.

Shrinkage was previously seen as an undesirable trait in resin and composite materials for architecture purposes but is a key property in these self-morphing materials as it helps realize a larger range of structures and scales.

Additionally, scalability of the structures was demonstrated, including a method that helps them cope with the effects of self-weight. Furthermore, the team presented a method to construct fiber composites with complex curvature distribution.

Furthermore, the need for an appropriate design tool where theory can be used to create complex 3D surfaces was also explored in the research. Physical simulation tools do currently exist, but these are not suitable for the design community’s desire to create complex 3D shapes. A software interface that allows computation of fiber distribution required for creating complex 3D shapes as well as the 3D surface for a given fiber pattern was demonstrated.

This research demonstrates that 3D self-morphing materials for large-scale use in architecture is feasible. The authors of the study have stated that it should serve as proof of principles, and the researchers point out that various subjects that still need to be studied and optimized before these materials can be used in the architecture industry.

Key Issues Addressed by the Technology

The requirements of the architecture industry for sustainable fabrication of materials including complex-curved materials are pressing and urgent. Fabrication techniques can be resource-intensive, and the impact of mold-based fabrication needs to be addressed and reduced. Currently, alternative techniques such as active bending and form-active molds are being explored.

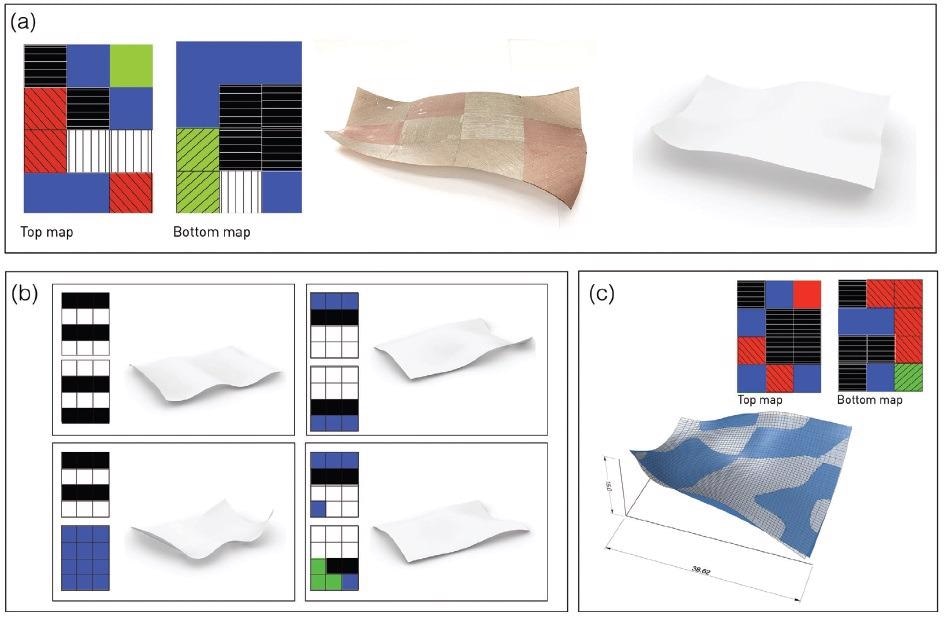

Complex curved panels design and fabrication through pixelization method a) fabrication of a panel according to top and bottom maps with colored tiles indicating fiber orientation (black -x aligned; white—y aligned; red and green—± 45°; blue- neutral, no fibers). A FC sheet of 800 mm × 600 mm(middle) compared to the simulated surface (right). b)Demonstration of forward-design process: various generating top and bottommaps (left) and their simulated surface configurations (right) (see experimental realizations in Figure S5, Supporting Information). c) Demonstration of inversedesign process: target surface was set as the surface obtained in simulation (a). Found surface (blue) compared to target surface (white). The standard deviation between surfaces is 0.53, over a global height of 15.0 (3.5% deviation). Note that the maps of fiber orientations differ from the original one in (a). Image Credit: Blonder, A & Sharon, E, Advanced Materials

Furthermore, there is the issue of the transportation volume of materials. Realizing an off-site fabrication method where flat materials can be transported efficiently to the site and rapidly take form once positioned will have benefits for transportation challenges and on-site management. Other key aspects that need to be addressed include change of scale and materials and the design of specialist equipment for on-site fabrication.

What This Research Means for the Future of Architecture

Several key challenges have been addressed in the research to realize truly smart, self-morphing materials that are sustainable and can be implemented at an architectural scale. Innovation like this is moving the architecture industry forward into the 21st century, significantly improving current practices in the field.

Further Reading

Blonder, A & Sharon, E (2021) Shaping by Internal Material Frustration: Shifting to Architectural Style [online] Advanced Science | onlinelibrary.wiley.com. Available at: https://onlinelibrary.wiley.com/doi/full/10.1002/advs.202102171

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.