As the world moves toward a low-carbon economy, the need for batteries to store energy and power news products is increasing. Lithium-ion batteries are commonly used currently, but they suffer from resource scarcity and increased costs, making them insufficient for many applications such as storage in next-generation power stations. Alternatives need to be explored urgently.

Due to these challenges, batteries using potassium and sodium ions have emerged as viable alternatives. This is due to the abundance of resources and the relatively low cost of manufacture.

Cathode materials for fuel cells using sodium and potassium have been the focus of much research, creating an admirable library of materials for this use, but the situation with anode materials is different. Graphite has been explored, but it suffers from low performance and is insufficient in respect to capacity.

Hard carbon is a much more promising material for this new generation of batteries due to its structural and electrical properties. It has been extensively studied for its applications.

Hard Carbon as a Material for Batteries

Hard carbon is a material that has been explored for its application as an anode for sodium-ion and potassium-ion batteries. However, limitations with the material exist which prevent its current adoption for commercial applications. Hard carbon suffers from poor rate performance and low initial Coulombic efficiency, due to poor conductivity and irreversible reactions which form solid electrolyte phase films.

Additionally, natural polymers that act as precursors for hard carbon tend to melt and foam during pyrolysis, which is a commonly used fabrication method for hard carbon. This creates a large surface area and consequently, lessens the material’s initial Coulombic efficiency. Additionally, gas is created in the process. Traditional preparation methods suppress foam formation but are wasteful in terms of energy and time.

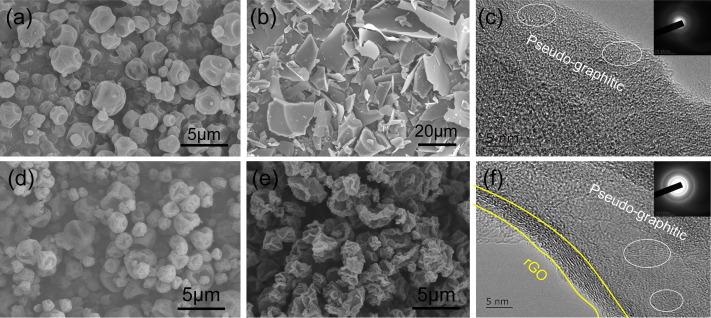

SEM images of samples before and after pyrolysis (a-b) HC and (d-e) HCG; HRTEM images of (c) HC and (f) HCG and the inset is the selected electron diffraction. Image Credit: Yan, L. CEJ

In order to facilitate its commercial adoption for the battery industry, the properties of hard carbon must be improved, and current fabrication techniques are woefully inadequate. Therefore, alternative strategies are required. Now, a team of researchers in China has demonstrated a hard carbon manufacturing process that significantly improves its properties and function as an anode.

Improving the Performance of Hard Carbon

The study, published in the Chemical Engineering Journal in November 2021, has demonstrated a new process for improving the rate performance of hard carbon, making it a more commercially viable material that meets the global battery industry’s needs.

The process uses a low-temperature pyrolysis technique which uses spray-drying to prepare microspheres of hard carbon/graphene carbon with a favorable reduction in their surface area. Starch granules are coated with graphene oxide sheets and pyrolyzed at 900oC. This makes them into a high initial Coulombic efficiency anode. By coating starch in-situ with graphene, energy consumption and preparation time are improved. This process is used instead of pretreatment methods traditionally used to avoid the formation of starch foams.

Benefits for the material when prepared with this process include a microcrystalline structure that is highly ordered, good conductivity, and abundant mesopores in the structure. The hard carbon/graphene carbon materials produced by the process have the highest initial Coulombic efficiency of any carbon-based anode currently in existence.

Kinetics analysis of the material revealed a significantly improved rate performance, the performance being better in potassium ion batteries than silicon ion batteries. Fuel cells with these anodes display excellent energy density.

The work in the study demonstrated a process for creating hard carbon-based anodes with improved properties that create fuel cells with lower energy consumption and expand the materials that can be used for silicon ion and potassium ion batteries. This process is scalable, giving it real potential to create fuel cells that meet the energy demands of the future.

What Does This Mean for the Future?

The world is going to need a lot more battery storage as we move away from conventional fossil-fuel power stations, as well as for electric vehicles and other environmentally friendly applications. However, there is only a finite supply of lithium for current battery types, so new fuel cells need to be explored.

Manufacturing hard carbon/graphene carbon anode materials with superior rate performance and better initial Coulombic efficiency will provide efficient solutions for the problems of commercial adoption of the new generation of fuel cells by multiple industries.

Further Reading

Yan, L (2021) In-situ graphene-coated carbon microsphere as high initial Coulombic efficiency anode for superior Na/K-ion full cell [online] Chemical Engineering Journal 133257 | sciencedirect.com. Available at: https://www.sciencedirect.com/science/article/abs/pii/S1385894721048324

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.