Due to their high energy density, long life span, and environmental friendliness, lithium-ion batteries (LIBs) have become the most promising storage devices for electric vehicles and hybrid electric vehicles. However, the swift development of electronic industries requires LIBs to deliver higher energy density to meet the demands of high-performance electronic devices.

Electrodes such as cathodes and anodes usually determine the capacity of LIBs. Carbonaceous materials, especially graphite, have been widely used in commercial LIBs devices. However, these conventional anodes are limited by their low theoretical capacity (372 mAhg-1).

Transition Metal Oxides as Anodes in LIBs

To increase the energy density of LIBs and replace graphite, several other types of anode materials such as metal oxides, metal sulfides, and alloys have been developed. Among these materials, transition metal oxides (TMOs), which have a theoretical capacity 2-3 times higher than that of graphite, are a good replacement for graphite and the most promising anode materials for LIBs.

However, TMOs are generally plagued by serious volumetric expansion during the repeated cycle process, which leads to electrode pulverization, thus exhibiting poor cycling stability. To improve their structural stability and electrochemical performance, rational design of anode materials has been confirmed as an effective strategy as illustrated in an article published in the Journal of Alloys and Compounds.

TMOs with Hollow Structures are Better Anodes for LIBs

TMOs with hollow, mesoporous, and hierarchical structures have been developed for use as high-performance anodes for LIBs. Due to the substantial advantages given by unique architecture, TMOs with hollow structures attract the most attention among them.

The hollow interior can serve as a buffer space to accommodate the large volume variation during the charge/discharge process, effectively preventing structural collapse. As a result of this, the cycling performance of the anode materials can be much improved.

Besides, the large surface area provided by such a hollow structure provides electrode materials with sufficient Li storage sites. Furthermore, materials with a hollow structure can provide shorter diffusion paths for both Li+ ions and electrons compared with bulk materials. This effectively facilitates the kinetic process, resulting in a much-improved rate capability.

Template-Based and Template-Free Synthesis of TMOs

Being straightforward and versatile, the template-based method is the commonly used strategy to prepare materials with hollow structures. Generally, the preparation of a precursor with a core-shell structure and the removal of the core via thermal decomposition or chemical etching are two necessary steps in the construction of a hollow structure through a template-based method. However, this procedure is costly and leads to environmental pollution.

In addition, the geometrical configuration of hollow structures prepared by the template-based method is usually spherical because it is difficult to uniformly deposit shell materials onto a core substrate with a high curvature surface.

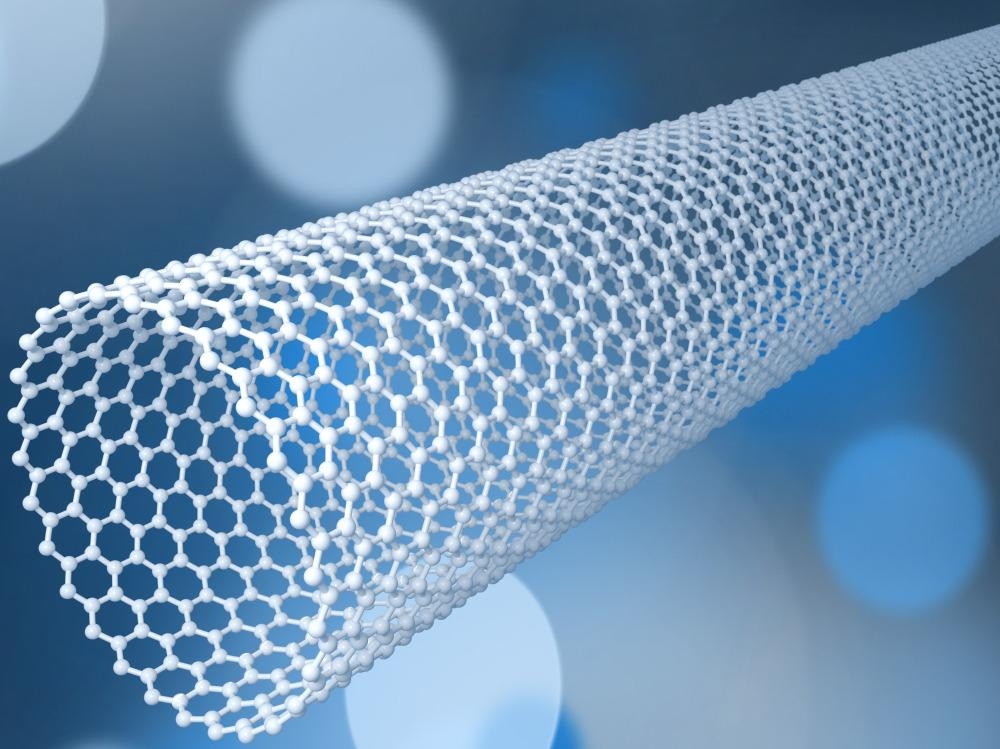

Image Credit: ustas7777777/Shutterstock.com

Several template-free methods based on hydrothermal/solvothermal process, Kirkendall effect, Ostwald ripening, and electrospinning technique have disadvantages such as a long reaction period and low yield, which severely limit their application. Hence, it became necessary and urgent to develop facile and efficient synthesis protocols for the controllable preparation of hollow structures of various TMOs like Co-based TMOs nanotubes.

A Two-Step Template-Free Method to Synthesize Co-Based TMOs

In this synthetic protocol, only two simple steps including a wet-chemical reaction to prepare a solid precursor and a calcination process were required, effectively avoiding the usage of additional templates. Benefitting from this protocol, Co3O4 and binary Co-based TMOs including MnCo2O4 and NiCo2O4 could be easily prepared by using different metal salts.

Characterization technologies such as transmission electron microscopy (TEM), X-ray diffraction (XRD), and X-ray photoelectron spectroscopy (XPS) were used to analyze the structure and composition of the as-prepared Co-based TMOs, which demonstrated the hollow tubular structure of all samples.

By tracing the morphology evolution of the precursor of Co3O4 nanotubes calcined at different temperatures, it was found that the crystallization of TMOs and the removal of organic compounds were carried out simultaneously during the calcination process, which has a crucial influence on the formation of the desired hollow tubular structure.

The synthesis of the hollow structure was achieved by a simple calcination treatment without the usage of additional templates. The crystallization of TMOs and the thermal decomposition of organic compounds together prompted the formation of the desired hollow tubular structure during the calcination process demonstrated by the morphology evolution of solid nanorod precursor calcined at different temperatures.

Template-Free Co3O4 Nanotubes Exhibit Enhanced Performance

When used as anodes for LIBs, the template-free Co3O4 nanotubes exhibited much better cycling performance and rate capability than that of the solid Co3O4 nanoparticles. The improvement in electrochemical performance could be attributed to the favorable hollow tubular structure, which provided sufficient active sites, a shorter diffusion path, and enough buffer space for the electrochemical repeated charge/discharge process.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.