The final qualities of 3D printed materials are determined by how all production parameters are established and/or varied. These include those engaged in the curing step as well. Curing effects on stereolithography (SLA) rely on numerous factors, including temperature, curing time, and radiation wavelength.

Importance of Additive Manufacturing

Additive manufacturing (AM), often known as 3D printing, is one of the most transformative technologies of our time. 3D printing may be used to create a highly precise virtual model, which is notably valuable in the aerospace and automobile sectors.

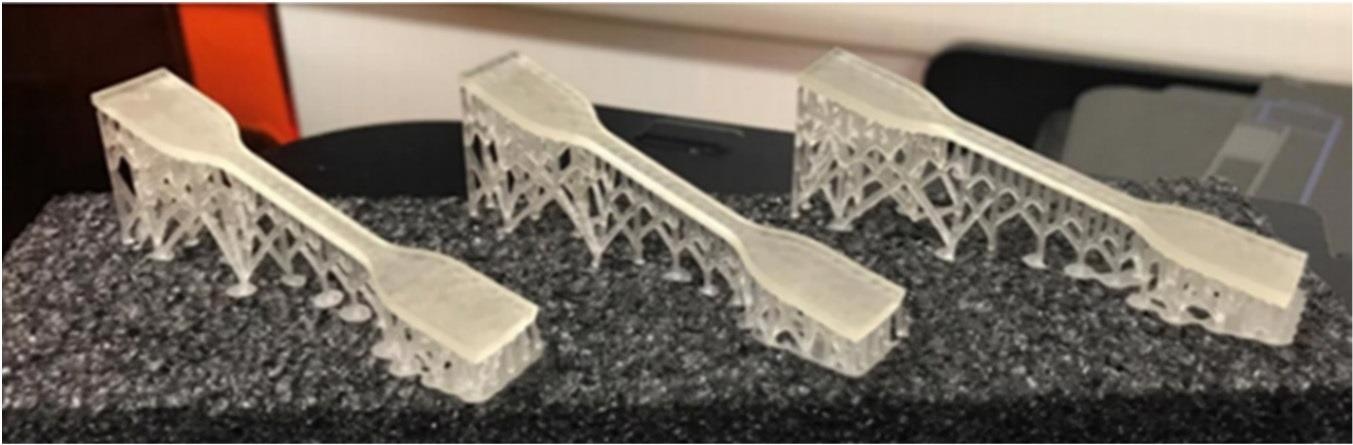

Three-dimensional printed 5A specimens (Form 2, Standard Clear Resin). Image Credit: Riccio, C., Applied Mechanics

It offers a wide range of possible uses, including portable technology with various biological functions and other biotechnological applications, such as custom-made implanted devices.

Limitations of Additive Manufacturing

Although Additive manufacturing is one of the most renowned methods yet it has several limitations associated with its applications. The limited manufacturing throughput and associated expenses are important reasons restricting the usage of AM. Furthermore, due to differences in manufacturing procedures, 3D printed items may have different dimensions than CAD models.

Innovative Stereolithographic Technique

Stereolithography is the method of particular relevance in this investigation (SLA). The goal of SLA is to print tiny layers of a corrosion-resistant material, add and combine them on top of one other to form solid, three-dimensional things. This approach allows for the creation of designs with innovative geometry that would be difficult or even impossible to accomplish using layer-by-layer fabrication techniques. In turn, these geometrical features can increase a module's engineering performance.

SLA employs a photopolymerization technology to produce solid components by selective solidification. It enables excellent component precision, precise surface finish, and strong mechanical qualities.

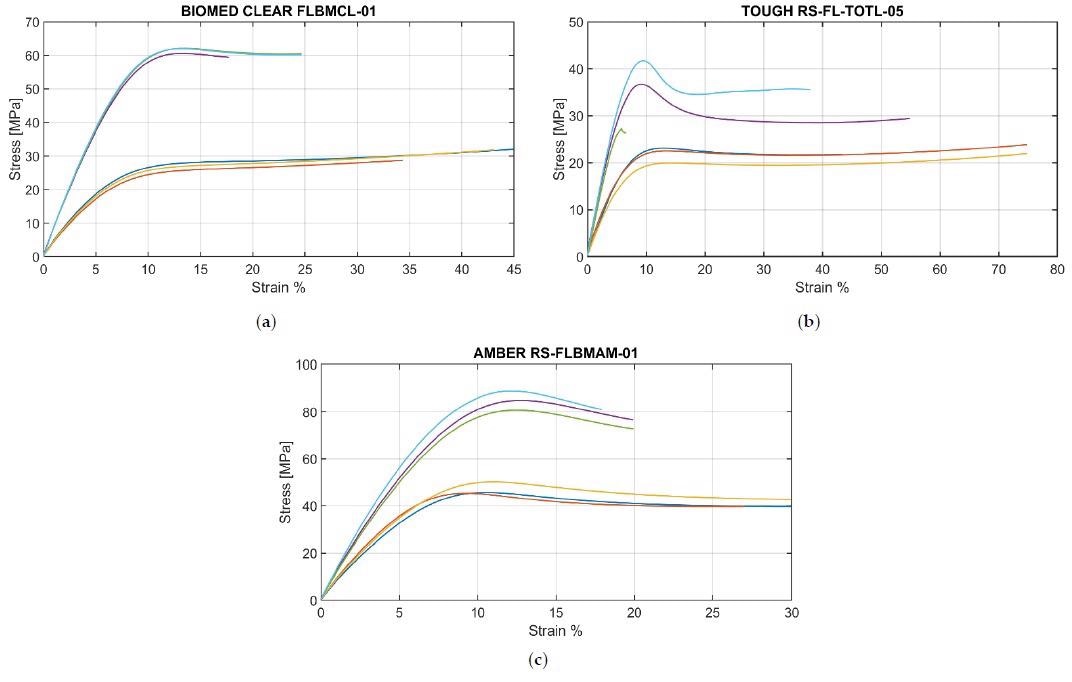

Stress-strain curve green and post-cure of BioMed Clear (a), Tough (b), and BioMed Amber (c) Resins. Image Credit: Riccio, C., Applied Mechanics

The significance of the Curing Treatment Method

To speed up curing, three-dimensional printed items can be treated in an ultra-violet (UV) oven. UV radiation causes the development of extra chemical bonds, which aids the hardening resin in achieving increased structural strength and stability.

Temperature dependency is a key feature of the curing process, as heat speeds the process. As the curing temperature rises, it takes less time to achieve a state in which the material has the best mechanical characteristics imaginable, resulting in a quicker cure rate.

The enhanced movement of free radicals in the molecular chains can be linked to the influence of UV curing at high temperatures on mechanical characteristics. It was discovered that annealing with a 405 nm light source produced the best elasticity and compressive strength.

There has been no comprehensive assessment of the curing effects on a wide number of regularly used SLA products, which was the goal of the latest research.

Commercial SLA Resin Synthesis

Commercial resins for 3D stereolithography are typically composed of oligosaccharides and monomers coupled with one or more photoinitiators, as well as additional components. These components are used to stabilize the resin, increase its reaction speeds, and improve its other qualities.

The most recent investigation used six type 5A specimens that were 3D printed for each resin following the BEN-ISO 527 standard.

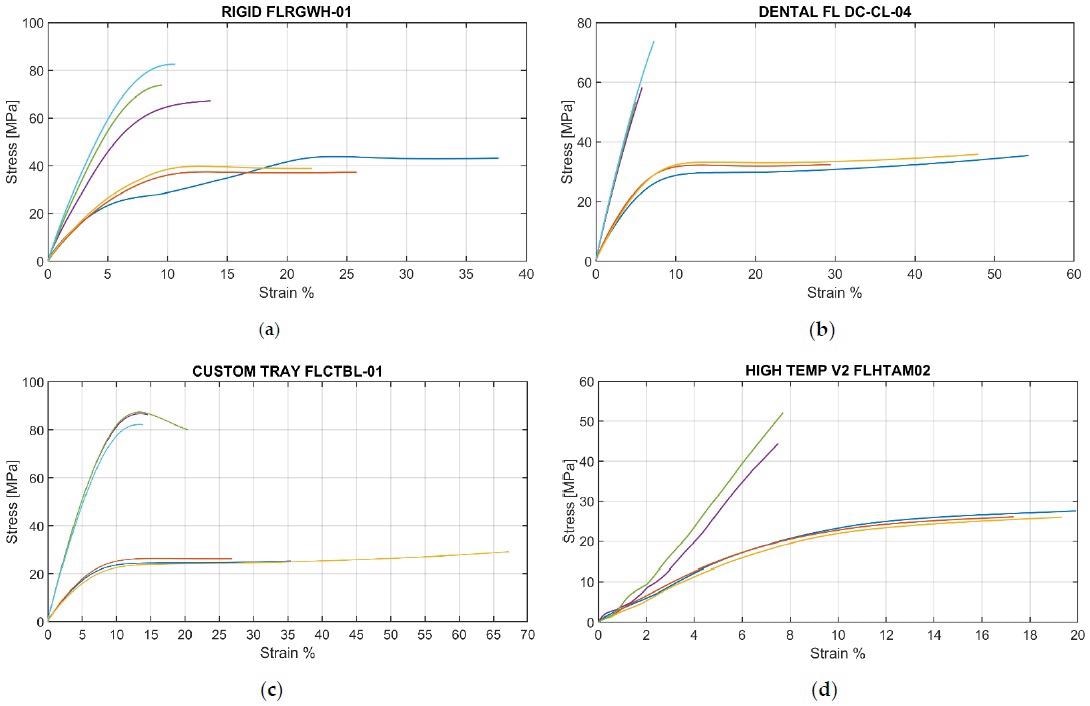

Stress-strain curve green and post-cure of Rigid (a), Dental LT Clear (b), Custom (c), and High Temp (d) Resins. Image Credit: Riccio, C., Applied Mechanics

Research Findings

The researchers found that owing to the curing, the tensile toughness and elasticity values of each resin rose. The substance became more friction resilient in all situations, with a minimum increase in strength properties of 29% for Tough Resin and a maximum increase of 215 percent for Custom Tray Resin.

All three resins enhanced their breaking load and Young's modulus values as a result of curing treatment. The curing procedure increased the resistance of both resins (breaking load increased by 36% for Tough 1500 Resin and 59% for Tough 2000 Resin), as well as yield strength and stiffness.

The resilience of the material and inherent toughness underwent a notable increase as well.

Although a few materials showed notable variance, the materials became more brittle after the process. According to the results of the tests, the curing process can cause some resins to have a more fragile characteristic.

Limitations of the Curing Process

In general, the curing procedure has the critical drawback of significant enhancement of the brittle nature of the material—the shift from ductility to brittle results in a significant loss of toughness.

In short, all resins' Elastic modulus and compressive strength improve during the curing process. However, the technique lowers the flexibility of all resins, creating brittle behavior in some circumstances. Still, the advantages of the curing process outweigh the limitations and are the sole reason it is utilized in various industries.

References

Riccio, C., Civera, M., Ruiz, O. G., Pedulla, P., Reinoso, M. R., Tommasi, G., . . . Surace, C. (2021). Effects of Curing on Photosensitive Resins in SLA Additive Manufacturing. MDPI Applied Mechanics. https://www.mdpi.com/2673-3161/2/4/55

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.