Superhard materials are virtually incomprehensible solids with high electron density and high bond covalency. As a result of these unique properties, they are of significant interest in certain industrial areas such as abrasives, cutting tools, disc brakes, and wear-resistant and protective coatings. As such superhard materials are widely used in many industrial applications, like mining, defense, and space industries.

Mechanical hardness is typically used to gauge the applications of materials in machining and manufacturing industries using the Vickers hardness test, superhard materials are those that exceed hardness values of 40 gigapascals.

Diamond is the hardest known material used in industrial applications and while scientists have been synthesizing diamonds for decades the process necessitates high pressure and temperatures which can yield high costs. Therefore, researchers are often seeking alternative superhard materials that demonstrate the appropriate hardness and thermal stability at relatively low costs.

New research has developed superhard transition-metal borides through solid solution effects and grain boundary strengthening. Recently published in Accounts of Materials Research, the researchers describe their progress and review the factors that contribute to the material’s hardness.

“Inspired by the highly covalent bonding network found in diamond, our group has focused its efforts on designing new superhard materials by combining incompressible transition-metal atoms with light elements (e.g., boron and carbon),” says co-author professor Sarah H. Tolbert in the Department of Materials Science and Engineering, UCLA.

Superhard Transition-Metal Borides

The team started working with osmium dioboride (OsB2), which, although not a superhard material, by adding boron to the Os lattice significantly boosts the corresponding hardness factor. “Since our introductory work on OsB2, we have produced a range of superhard transition-metal borides with the aforementioned design parameters, including ReB2, WB4, and MB12 and their solid solutions,” explains Tolbert.

Hardness as a mechanical property is a result of both intrinsic and extrinsic effects and depends on the chemical bond strength and energy dissipation at grain boundaries, respectively. Materials that are intrinsically hard (e.g., diamond) have high resistance to both volume and shape changes (bulk modulus and shear modulus, respectively).

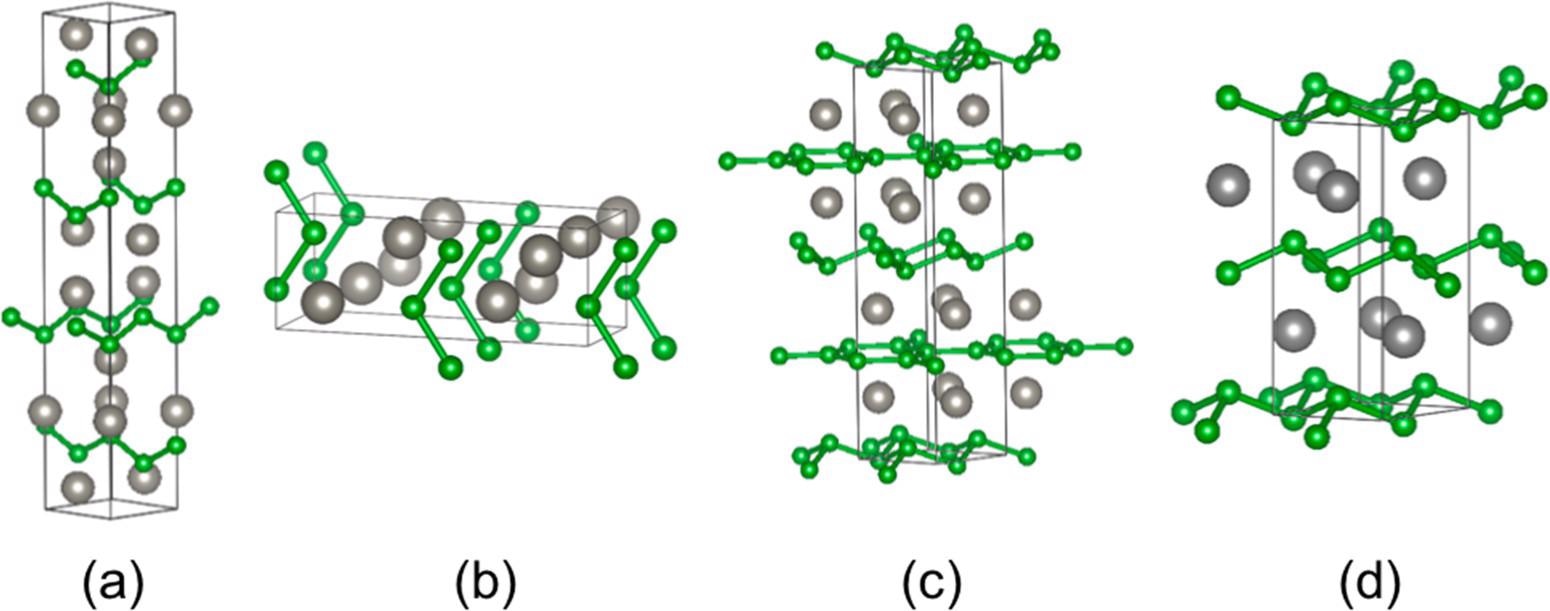

Crystal structures of (a) tetragonal α-WB, (b) orthorhombic β-WB, (c) WB2, and (d) ReB2. Gray atoms represent metals, while smaller, green atoms represent boron. Image Credit: Lisa E. P et al., Accounts of Materials Research

Solid solution formation is a technique that can be applied to increase the intrinsic hardness of a material, this process is where one type of atom is substituted for another atom. Conversely, extrinsic effects can be introduced by creating smaller grains and increasing the grain boundaries of the material.

“Both solid solution effects and grain boundary hardening impede the dislocation motion by introducing nonuniformity into the crystal lattice, consequently leading to higher hardness,” says Tolbert. The metal borides created by the UCLA team were formed at ambient pressure employing high-temperature solid-state techniques including arc melting and molten flux synthesis.

Machine Learning for Data-Driven discovery

One of the advances that the UCLA researchers introduced into their work was the inclusion of machine learning for the high-throughput screening of data. Machine learning has become a useful tool for materials discovery and data-driven discovery has been recently used to reveal new compositions for superhard materials.

While it is relatively easy to analyze the extrinsic properties of superhard materials, intrinsic properties such as electronic configurations, atomic radii, and chemical bond strength are much more difficult to review. However, machine learning capabilities deliver promising results in the field of data-driven discovery for superhard materials.

“Using ensemble learning designed to rule out hypotheses outliers after multiple training runs, algorithms achieving high accuracy (R2 = 0.97) were created and 68 superhard materials were discovered from a set of 66,000 compounds in Pearson’s crystal data set, a reasonable value because these materials are scarce,” explains Tolbert.

Consequently, the development of superhard, ultra-incompressible materials could lead to further advances in machining and manufacturing industries as well as finding use in diverse applications such as in the mining and space industries.

The team at UCLA discovered that transition metals with high valence electron density coupled with small, covalent-bond-forming atoms, such as boron, can potentially be ideal candidates for superhard materials.

The study highlights the design of superhard metal borides and considers the factors that contribute to their superhard properties. Furthermore, Tolbert explained that the work explores future avenues for designing and developing superior materials to meet the needs of next-generation engineering applications.

References:

Hardening Effects in Superhard Transition-Metal Borides Lisa E. Pangilinan, Shanlin Hu, Spencer G. Hamilton, Sarah H. Tolbert, and Richard B. Kaner Accounts of Materials Research Article ASAP DOI: 10.1021/accountsmr.1c00192 https://pubs.acs.org/doi/10.1021/accountsmr.1c00192

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.