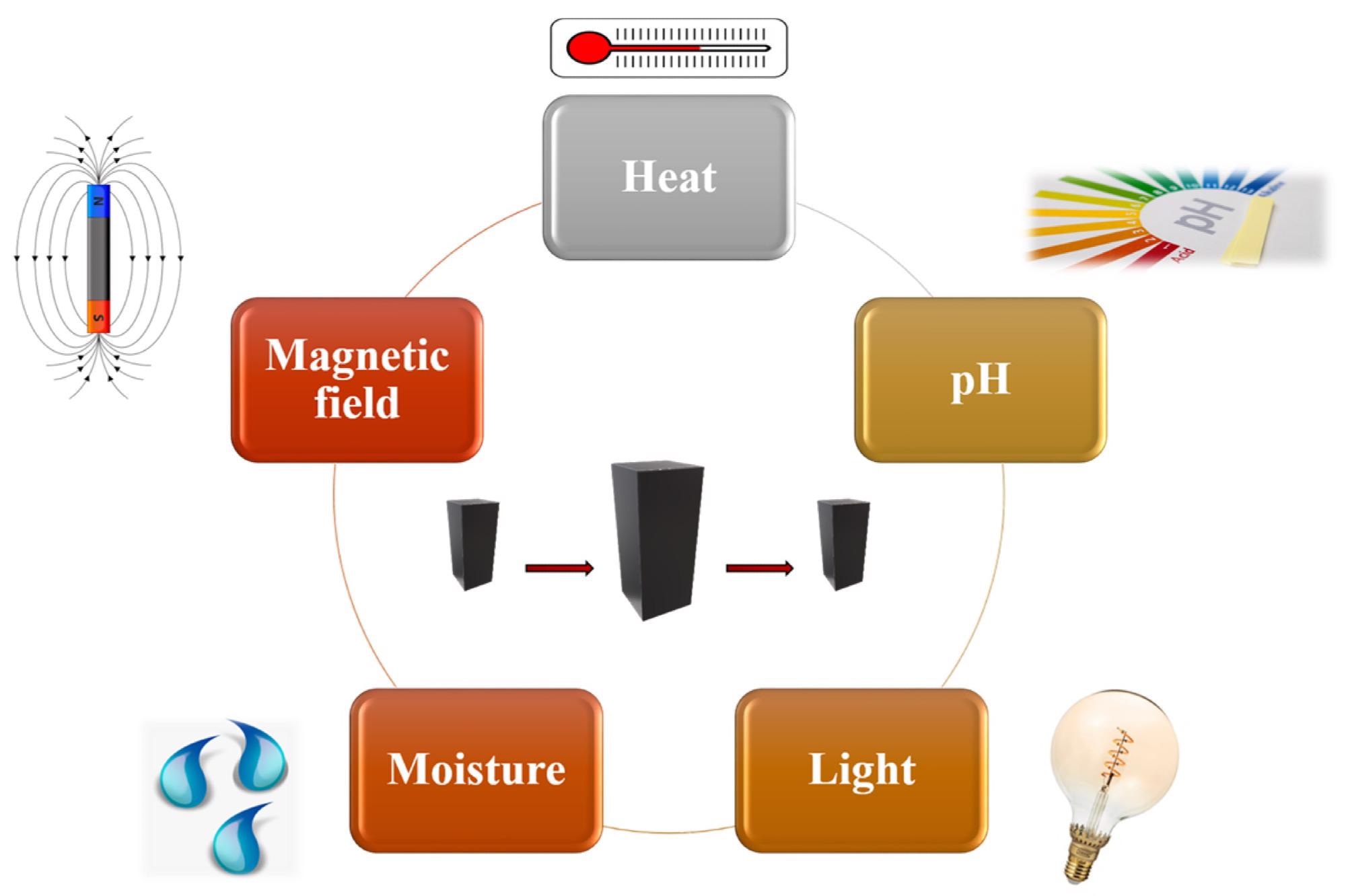

Shape-memory polymers have become a key research area in advanced materials research due to their ability to return to their original shape from a temporary one when external stimuli, such as light, magnetism, electricity, moisture, pH, and temperature, are applied. These smart materials can memorize both single and multiple temporary shapes.

However, this smart shape-morphing ability is not an intrinsic characteristic of these materials; rather, it is achieved by designing the polymer’s molecular structure and setting the programming and recovery stages. These stages are required to set the original and temporary shape. These advanced materials require switching domains.

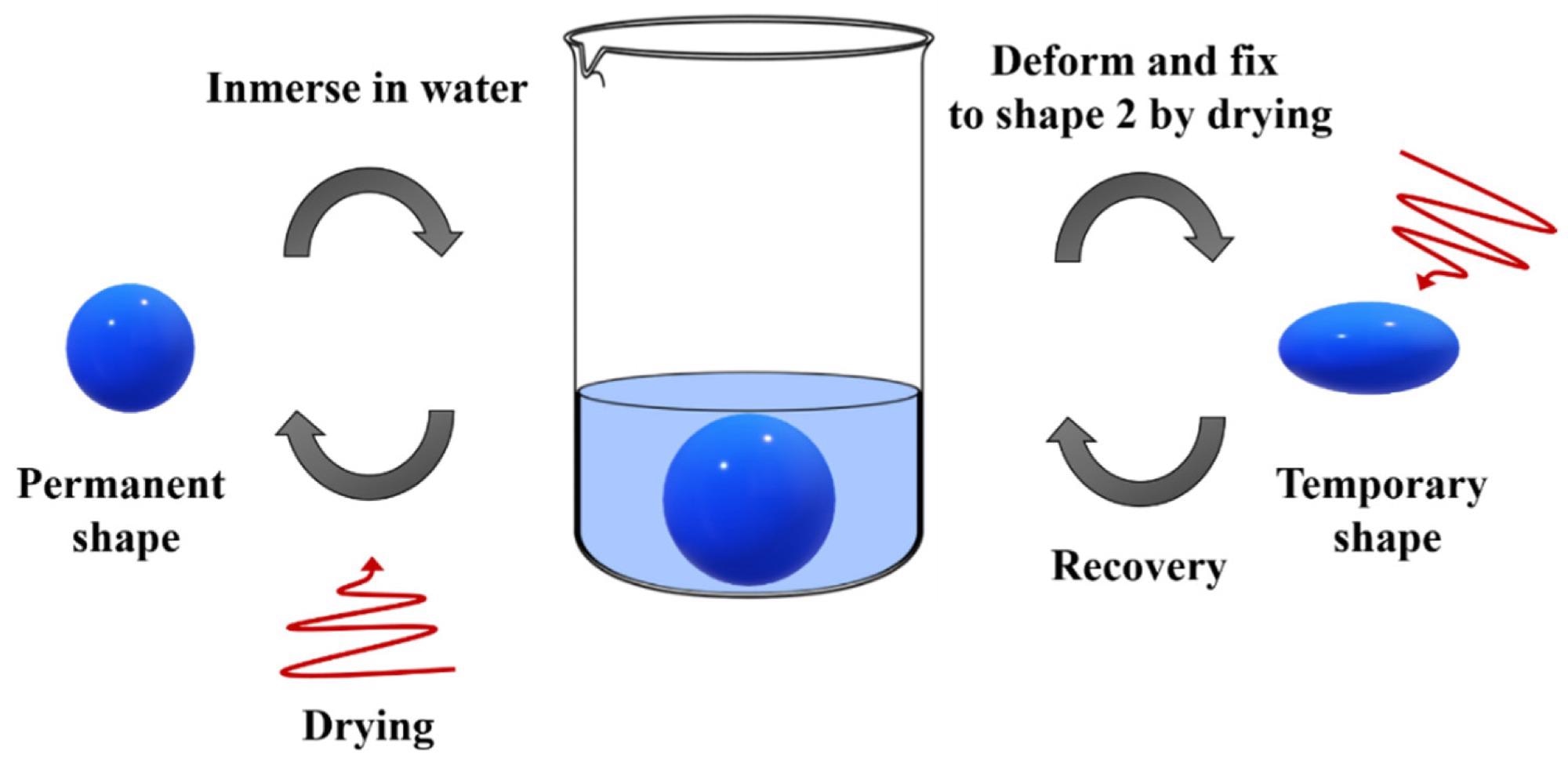

Chemical or physical network points within the materials determine the original shape of the material, whilst switching segments in the polymer fix the temporary shape. The switching points are the part of the material that responds to external stimuli. Different transitions such as reversible molecule cross-linking, glass transitions, liquid crystal transitions, and melting transitions are used to establish the temporary shape.

Stimuli-responsive shape-memory polymers. Image Credit: Salaris, V et al., Polymers

Thermally-induced shape-memory polymers are the most commonly used types of these smart materials. Heating them above a certain temperature (typically the glass transition temperature) causes a change from a rigid to a soft shape.

Deformation into the desired temporary shape occurs which corresponds to a change in entropy and molecular conformation when an external force is applied, and cooling below the glass transition temperature and the gradual removal of external force fixes the temporary shape through molecular chain freezing and the applied force is stored as entropic energy.

When reheated, there is an increase in mobility of the polymeric chains, releasing this entropic energy and driving the material back to its entropically favorable state which corresponds to its original shape.

Advantages of Shape-Morphing Polymers

There are many advantages to shape-morphing polymers that have facilitated their research focus in smart materials research. These include their relatively low cost, low density, biocompatibility, biodegradability, and high recoverable strain up to two hundred percent. Additionally, transition temperatures can be tailored in these materials.

Moreover, there is wide application potential for these materials in sectors such as biomedical sciences, bionics engineering, nano-optoelectronics, packaging, and aerospace.

Mechanism of water-responsive shape recovery. Image Credit: Salaris, V et al., Polymers

Electrospinning Shape-Morphing Polymers

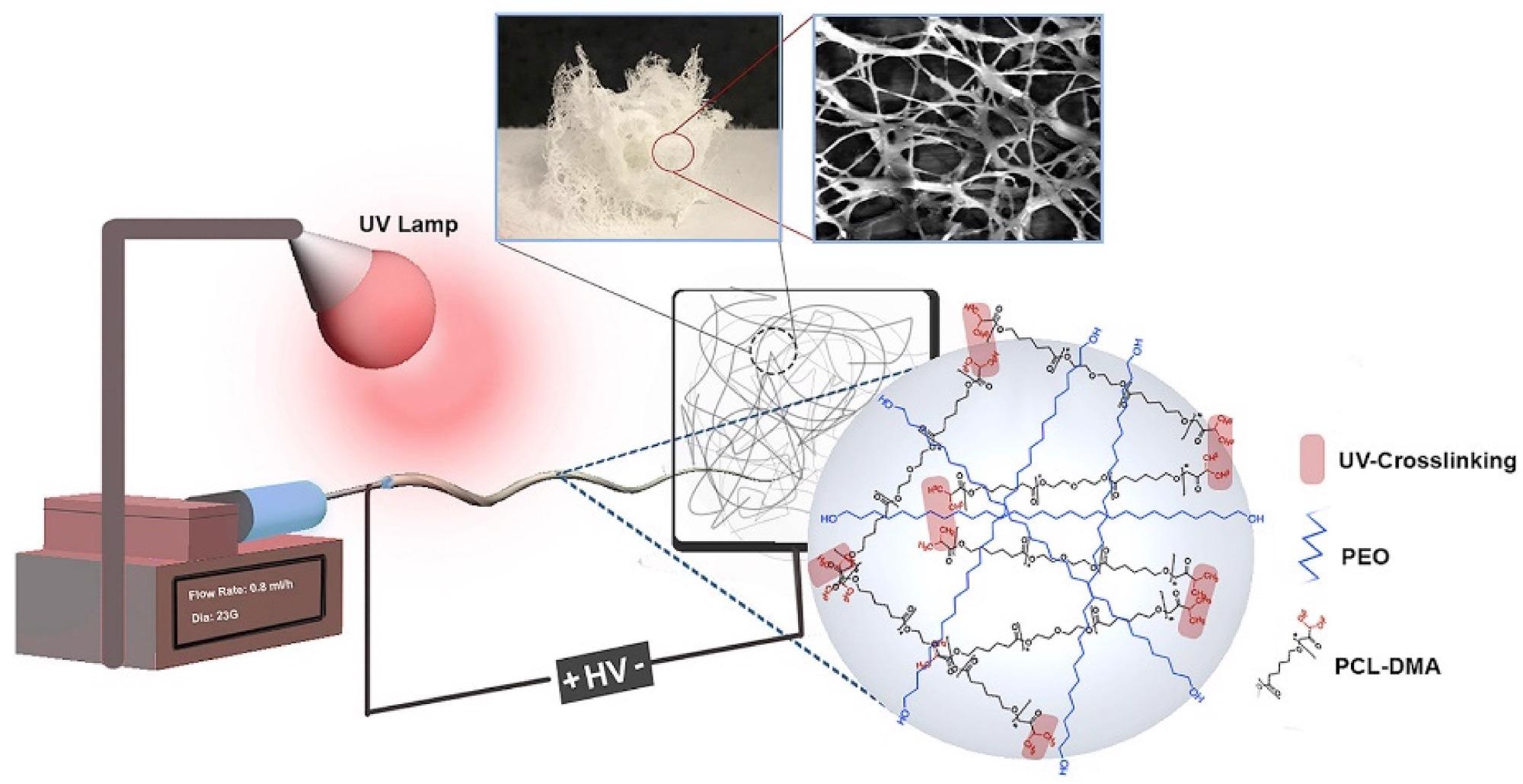

Electrospinning was developed in the 1930s and involves producing fiber mats by applying a jet of polymers in solution which is electrostatically charged. High voltage supplies are necessary, and the system consists of three main elements: a high voltage supply, spinneret, and collecting plate.

Shape-memory fibers have been studied due to intrinsic features such as high axial ratios and superior mechanical properties due to their molecular orientation. Multiple polymers such as polystyrene, PLA, and polyacrylonitrile have been used for electrospinning polymeric fibers. Fiber formation depends strongly on variables such as solution and solvent concentration, viscosity, and surface tension.

Electrospinning can produce fibers ranging in size from nanometers to micrometers. In recent years, there have been several studies on combining electrospinning with shape-morphing polymeric fiber behavior. However, with less than fifteen papers in the last seven years, this is regarded as a new and challenging research topic.

The Research

The review presented in Polymers has been published with the goal of pointing out the importance of these two issues in smart material design. Attention is specifically focused on the design and processing of electrospun shape-memory polymeric fibers and their potential commercial applications. The results of the review have demonstrated that the field needs further exploration, but there are promising results in fields such as sensors, electronics, and biomedicine.

Representation of the sponge-like 3D scaffold. Image Credit: Salaris, V et al., Polymers

The authors have analyzed 230 papers in the current literature, highlighting recent advances and providing current and future perspectives on shape-memory polymeric fibers. Particular attention has been paid to the application of electrospun shape-memory nanomaterials in medical sciences. These materials can mimic natural extracellular matrix structures for use as scaffold materials for applications such as tissue engineering and drug delivery.

The authors have noted considerable progress in the field of late, with optimization of these materials to improve their properties and extend their field of application and triggering stimuli such as magnetic fields, electrical fields, and pH. Novel fabrication techniques have extended their use to applications in fields such as robotics and aerospace engineering, such as energy harvesting.

Finally, the authors have noted that further research is needed to optimize the working parameters of the materials and significant challenges still need to be addressed. Furthermore, there exists the need for deeper efforts in material design to exploit the properties of electrospun shape-memory polymeric fiber materials for advanced applications in multiple fields, including electronics, robotics, and biomedical sciences.

Further Reading

Salaris, V et al. (2022) Shape-Memory Materials via Electrospinning: A Review [online] Polymers 14(5) 995 | mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/5/995

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.