Surface preparation is a necessary step in obtaining specialized substrates for corrosive layer deposition, spreading rheology, lubrication, liquid thermoflow control, and other activities. Other than the surface roughness morphology, which is mainly associated with the treatment process parameters (temperature, relative humidity, process time scale, and vibrations), solid material wettability is a key quality that reveals specific information on the component miscibility, surface chemical structure, and spatial heterogeneity.

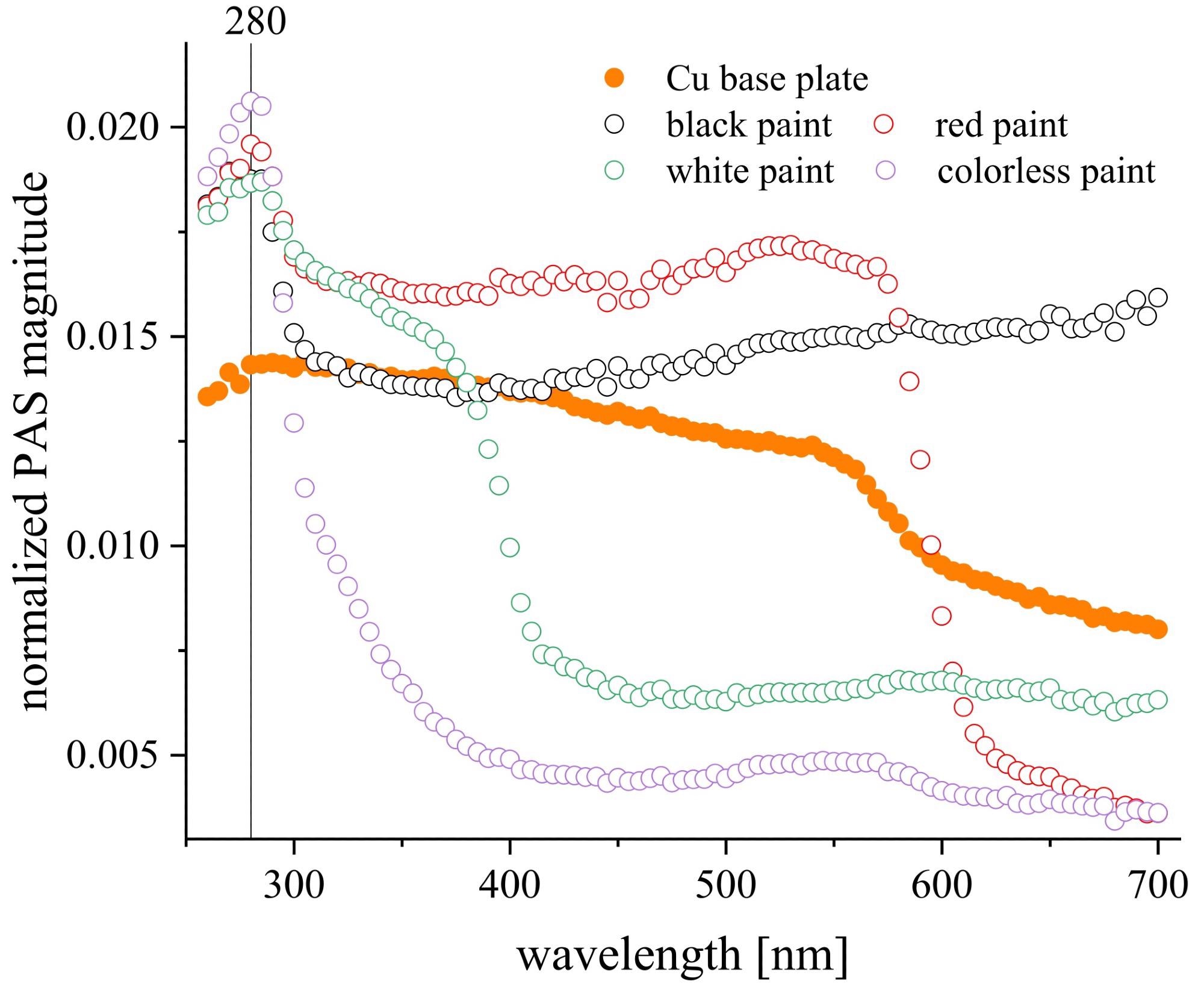

Normalized (with respect to carbon black) photoacoustic spectra for metallic Cu substrata-coated with spread paints; modulation frequency 120 Hz. The spectral band around λ ~ 280 nm points to the presence of a common polymeric component for all the paints investigated, while additional bands show a certain contribution of supplementary pigments. Image Credit: Pogorzelski, S et al., Materials

Wetting measurements based on contact angle (CA) determination are one of the most sensitive and widely used surface sensing techniques, with an analytical depth of only a few nanometers.

About the Study

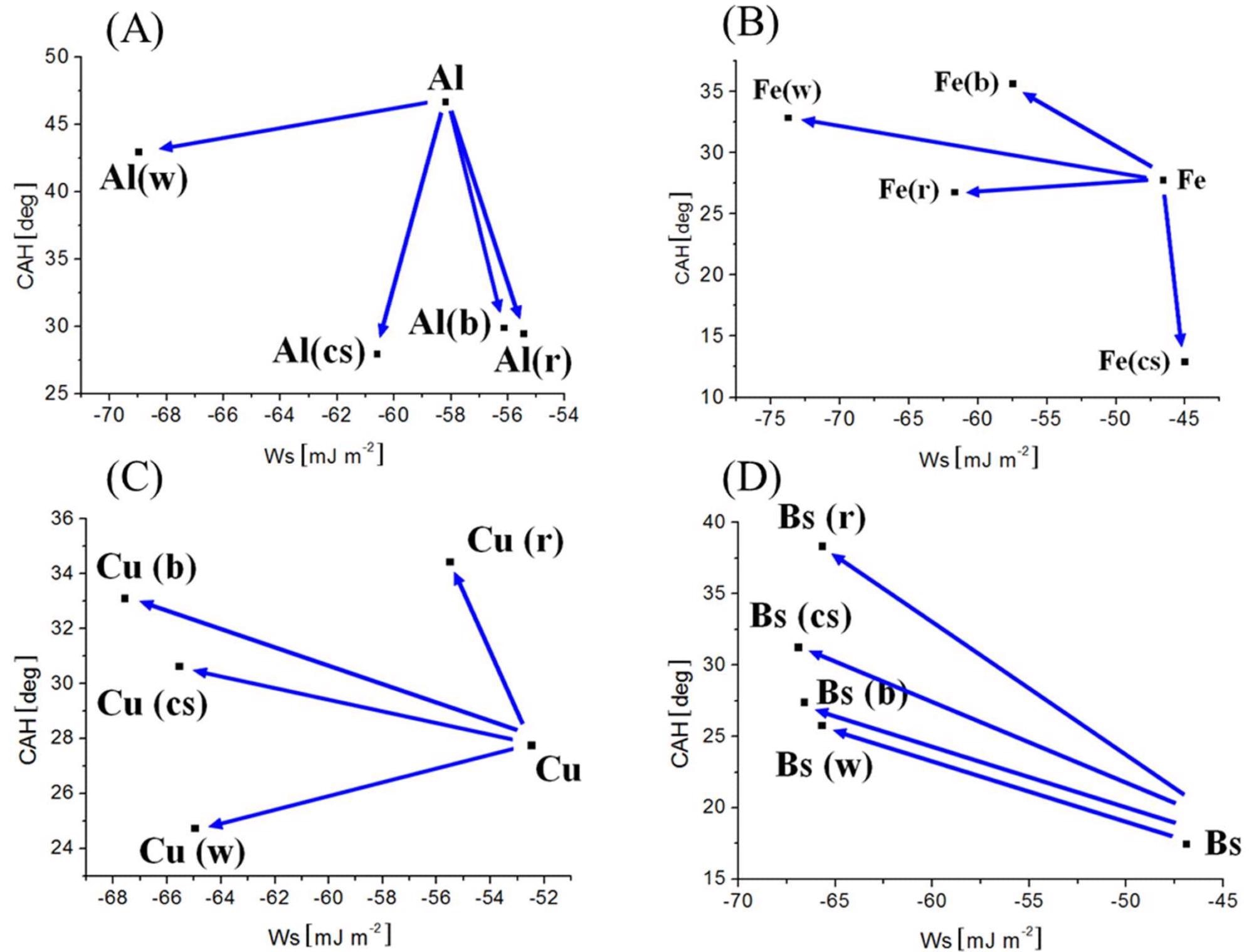

In the present study, the authors determined the wettability of metallic (Fe, Al, Cu, brass) surfaces that were painted using polymeric sprayed paints. The CA hysteresis (CAH) methodology was used to measure wettability, with dynamic CAs (advancing ΘA and retreating ΘR) identified using the inclined plate method. The equilibrium, ΘY, CAH = ΘA- ΘR, film pressure, Π, surface free energy, γSV, works of adhesion, WA, and spreading, WS, were all taken into account.

The effect of surface roughness and surface heterogeneity on wettability were studied using the registered 3D surface roughness profiles. Wetness measurements were performed based on the CA determination. Several theoretical approaches based on the so-called Young equilibrium CA, ΘY, were used to determine the solid surface free energy, γSV, and its components. The CAH routine was used to determine the solid substratum's interfacial interaction parameters and apparent surface free energy.

The 2D adsorptive film pressure, Π, surface free energy, γSV, work of adhesion, WA and spreading, WS were chosen as the condition level indicators of the analyzed polymeric paint-coated surfaces and clean metallic surfaces (reference), in addition to dynamic CAs.

The CAH was determined from the sessile drop shape examined with an inclined plate system and the axisymmetric drop shape analysis profile (ADSA-P) technique was used to derive CAs from the sessile drops. The experimental points distribution in the CAH vs WS plane was compared to the wettability evolution trend in order to discriminate between two surface processes that were occurring at the same time.

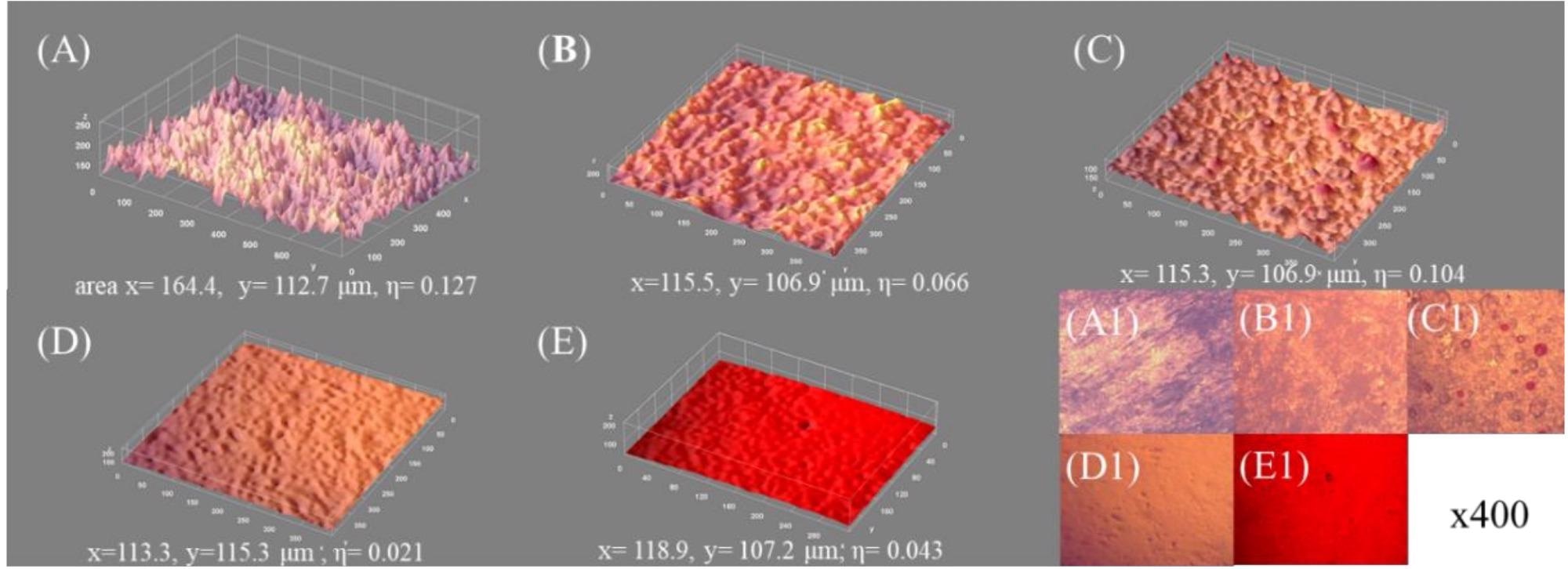

Confocal microscopy studies were performed to evaluate the 3D surface architecture using advanced image analysis programs, as well as to determine the correlations between the roughness fluctuation coefficient, η and the surface wettability parameters.

Contact angle hysteresis, CAH, as a function of work of spreading, WS, for metallic surfaces: (A) Al, (B) Fe, (C) Cu, and (D) brass alloy, clean-reference, and coated with color paints: w—white, b—black, r—red, and cs—colorless (transparent). The data evolution was indicated with the arrows in reference to the clean surface case. Image Credit: Pogorzelski, S et al., Materials

Observations

In this study, the researchers observed that the modified surfaces showed hydrophobic water/solid interactions, with a dispersive term contribution to γSV of (0.66–0.69). It was also observed that the clean metallic surfaces were discovered to be hydrophilic (ΘY<90°) with a high γSV, heterogeneous, and rough, with a significant CAH. The surface coverage showed the evolution of the parameters, with ΘA increasing, ΘR decreasing, γSV decreasing, WA decreasing, and WS decreasing, which were correlated to surface hydrophobization and revealed base substratum specific fingerprints. It was also observed that the CAH was linearly connected to the dimensionless roughness fluctuation coefficient, η.

Furthermore, CAH and ΘR were shown to be highly linked with the adhesive qualities of the surfaces. It was determined that. It was also demonstrated that the γSVd/γSV ratio fell from (0.74–0.77) γSV to (0.62–0.69) γSV when the metallic substrates were treated with paint. The following trend of the surface wettability energetics parameters' variability was observed: ΘY, ΘA, and ΘR increased, whereas CAH, γSV, Π, WA, and WS decreased. The Cassie–Baxter model predicted the stable thermodynamic state of the interface for rough surfaces (roughness parameter Rf > >1). It was also determined that the high Π values were linked to structured water molecules at the interface.

The Π values were found to be higher (29.2–42.9 mN m-1) than the reference sample (19.0–28.4 mN m-1), which was attributed to the effect of the interfacial arrangement of water molecules in the bulk phase on the surface treatment.

3D surface morphology and microscopic images (magnification 400×) of brass (clean) (A and A1, respectively) and covered with paints of different kinds: (B,B1) colorless, (C,C1) white, (D,D1) black, (E,E1) red; distance scale: 36 pixels = 10 μm; image-covered surface areas and surface roughness fluctuation coefficients, η, are given underneath. Image Credit: Pogorzelski, S et al., Materials

Conclusions

In conclusion, this article elucidated the variations in the wettability of metallic surfaces caused by different surface treatments. The authors emphasized that the CAH methodology, which is based on the three observable parameters ΘA, ΘR, and liquid surface tension, γLV, can be beneficial in studying surface-mediated processes like lubrication, liquid coating, and thermoflow. They also observed that in general, paint-treated metallic surfaces showed more hydrophobic surface qualities than untreated surfaces.

The authors also demonstrated that since CAH remained nearly identical for both the reference and treated samples, the surface wettability was attributed mostly to compositional changes at the interface rather than surface roughness and homogeneity.

Overall, the authors believe that the proposed CAH approach is a useful tool for monitoring and quantifying the wettability of surface-treated solid substrata that are also subjected to pollutant stress, as found in natural environment evaluations.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.