Natural fibers are being examined as a possible replacement for synthetic fibers in the manufacture of bio-based composite materials.

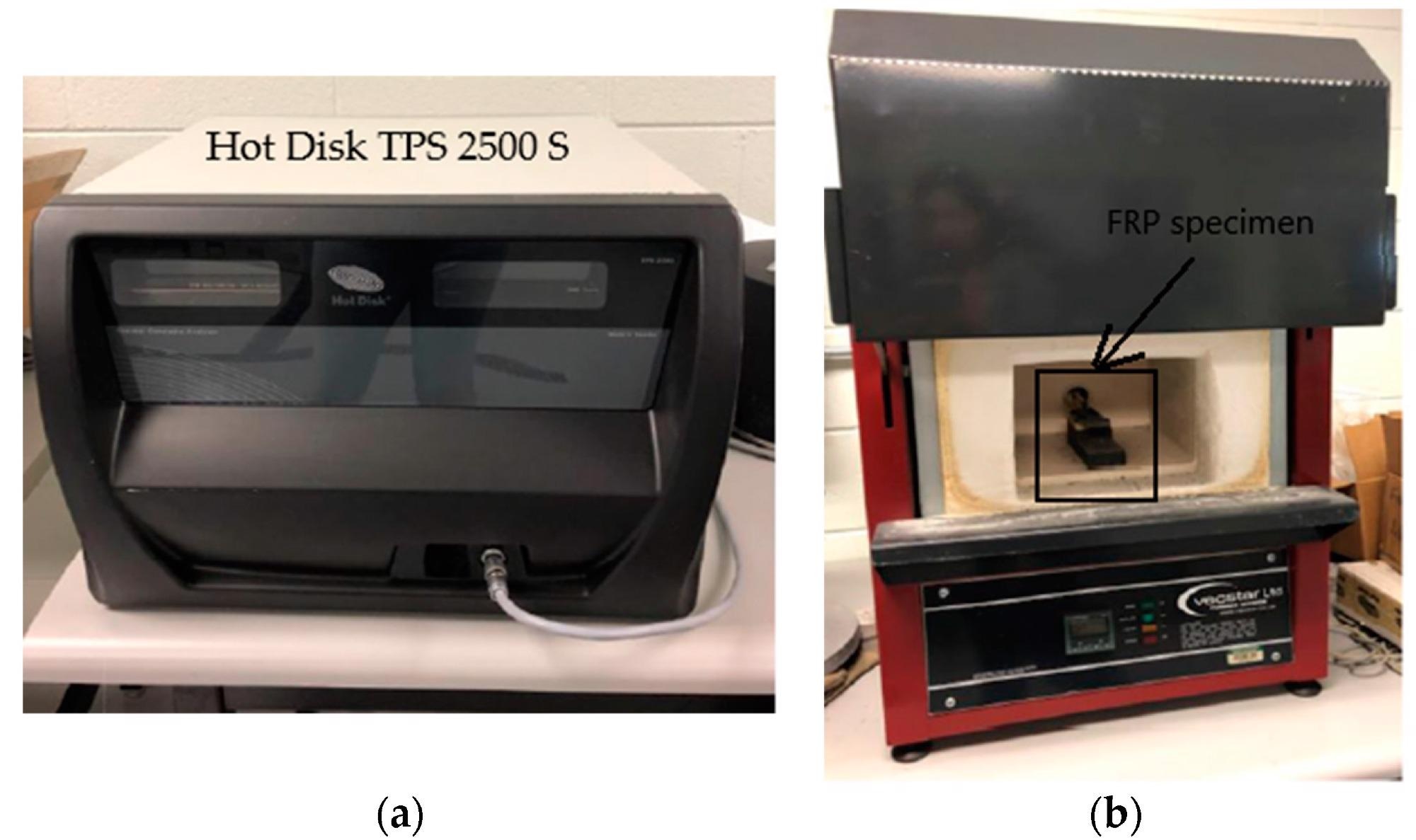

Equipment setup for hot disc method: (a) hot disc thermal constant analyzer and (b) furnace. Image Credit: Kodur, V et al., Polymers

Poor fire resistance and high flammability are the two main concerns with FRP composites, especially bio-based FRPs, and limit their use in structures. When compared to traditional construction materials, the properties of FRP fluctuate dramatically with temperature and must be properly tested using defined test procedures. While there is considerable guidance on the necessary test procedures for characterizing FRP composite properties at ambient temperature, there is less guidance on the test methods for describing capabilities at increased temperatures.

About the Study

In this study, the authors discussed the testing methodologies and processes for the evaluation of the properties of FRP materials at various elevated temperatures. The most appropriate specimen circumstances, testing regime, test methodologies, and other concerns related to testing at elevated temperatures were all discussed.

Furthermore, the applicability of the suggested test methodologies was demonstrated using typical FRP specimens in a case study. The applicability of the specified test methodologies for measuring bio-based FRP composites' high-temperature capabilities was also underlined.

The researchers presented a detailed analysis of test methods and procedures defined in current standards (including International Organization for Standardization (ISO) standards and the American Society for Testing and Materials (ASTM)) and published papers.

The team described the most appropriate test methods for high-temperature material characterization of FRP composites, including bio-based FRPs, in the temperature range of 20 to 600 °C. A review of the numerous test methods was carried out to evaluate the mechanical and thermal properties of synthetic FRP composites. In addition, the most appropriate test methodologies for characterizing important material characteristics of the FRP at elevated temperatures were discussed.

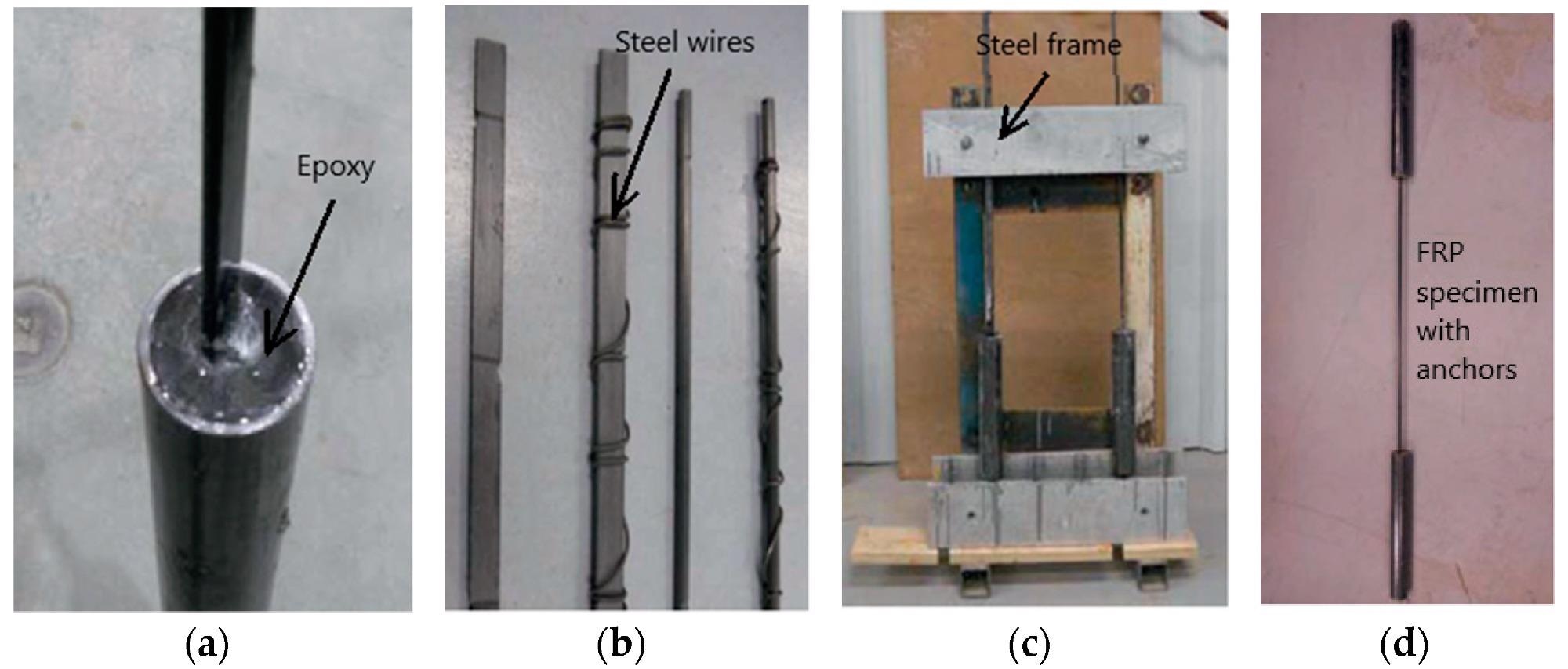

Fabrication of anchor system for FRP specimens indicating (a) epoxy filling, (b) steel wires, (c) steel frame, and (d) test specimen. Image Credit: Kodur, V et al., Polymers

Observations

The erosion of bond strength was reported to be rapid in the 20 to 200 °C temperature range, and the near-surface mounted (NSM) FRP only retained 20 to 30% of its initial strength at 200 °C. According to the results of the testing, the epoxy started to burn at roughly 400 °C, which caused damage to the FRP-concrete bond. At 400 °C for carbon FRP (CFRP) strips and 300 °C for CFRP rods, the bond strength was minimal. Concrete had compressive strengths of 50 MPa and 48 MPa after 90 days and 28 days, respectively.

The modulus and strength of CFRP specimens degraded gradually between 20 and 300 °C, then rapidly beyond 300 °C. The tensile strength and elastic modulus of NSM CFRP strips were determined to be 1641 MPa and 150.8 GPa, respectively, in room temperature tests, while the comparable values for CFRP rods were 1577 MPa and 130.9 GPa.

Several studies reported that since bio-based composites had a similar construction, the procedures and recommended guidelines for specimen conditions, anchor systems, heating and loading rates, and other factors could be used to conduct property tests on the bio-based FRP composites to generate suitable material property data in the temperature range of 20 to 600 °C.

The high-temperature property data from the tests could be used to enter relevant property relations into numerical models for the forecast of the capabilities of bio-based FRP under various fire exposure situations.

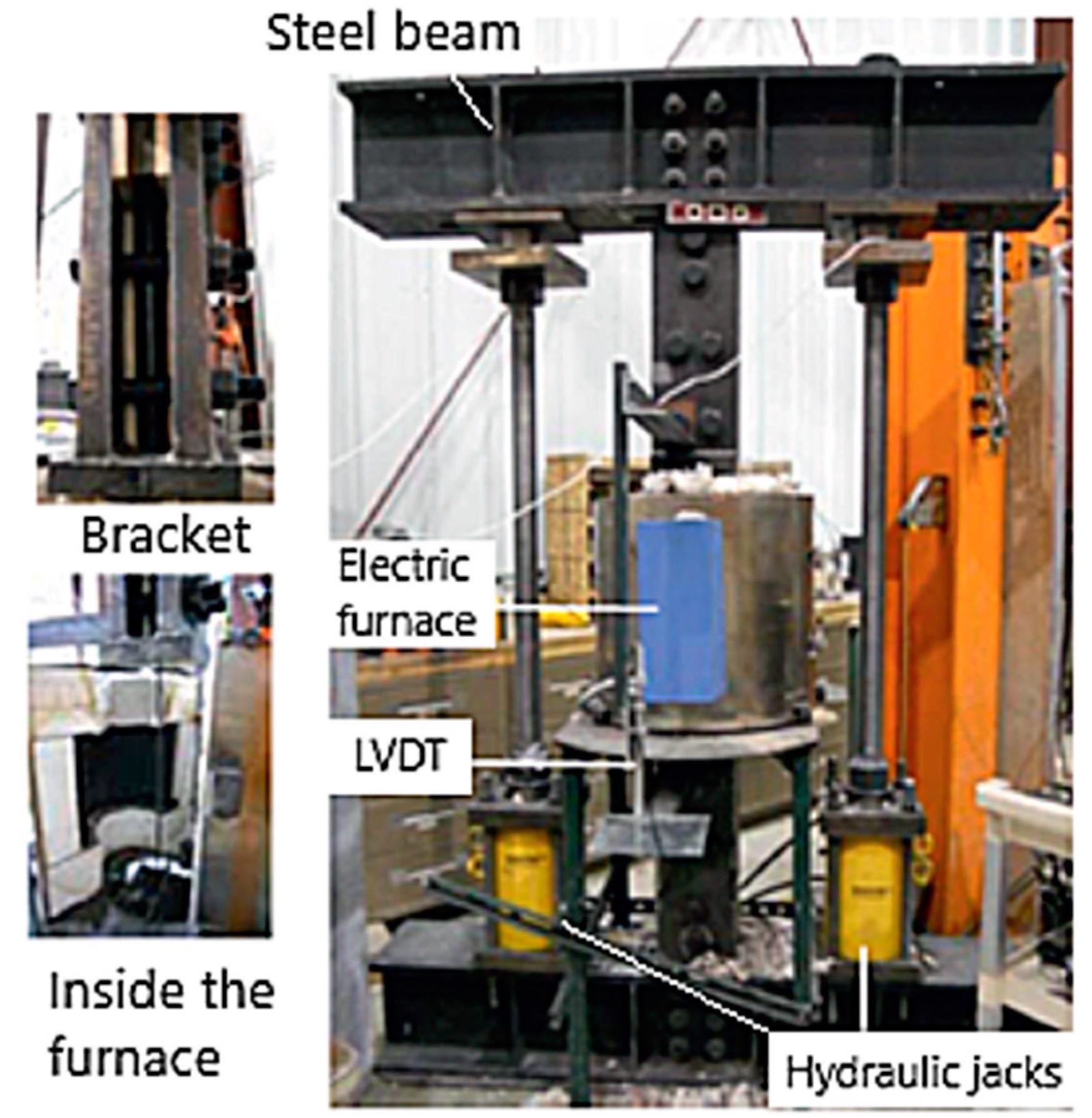

Test setup for FRP composite strength test at elevated temperatures. Image Credit: Kodur, V et al., Polymers

Conclusions

In conclusion, this study discussed the test procedures and methods for the evaluation of the mechanical and thermal properties of FRP composites at high temperatures. The most appropriate test procedures for high-temperature material characterization of FRPs were recommended based on the studied literature. In current codes and standards, no defined test methods or procedures were found for the characterization of the high-temperature properties of bio-based and synthetic FRP in the temperature range of 20 to 600 °C.

For characterization of the material properties of bio-based and conventional FRP composites in the 20 to 600 °C temperature range, efficient test procedures based on a review of test methods in published literature and current standards could be used. The case study demonstrated that the recommended test methodologies for the evaluation of mechanical and thermal properties of FRP composites could be used to accurately assess the FRP composites' high-temperature properties. The case study on conventional FRPs demonstrated that the recommended test methodologies are capable of capturing variations in thermal and mechanical properties at elevated temperatures.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Kodur, V., Venkatachari, S., Matsagar, V. A., et al. Test Methods for Characterizing the Properties of Fiber-Reinforced Polymer Composites at Elevated Temperatures. Polymers 14(9) 1734 (2022). https://www.mdpi.com/2073-4360/14/9/1734